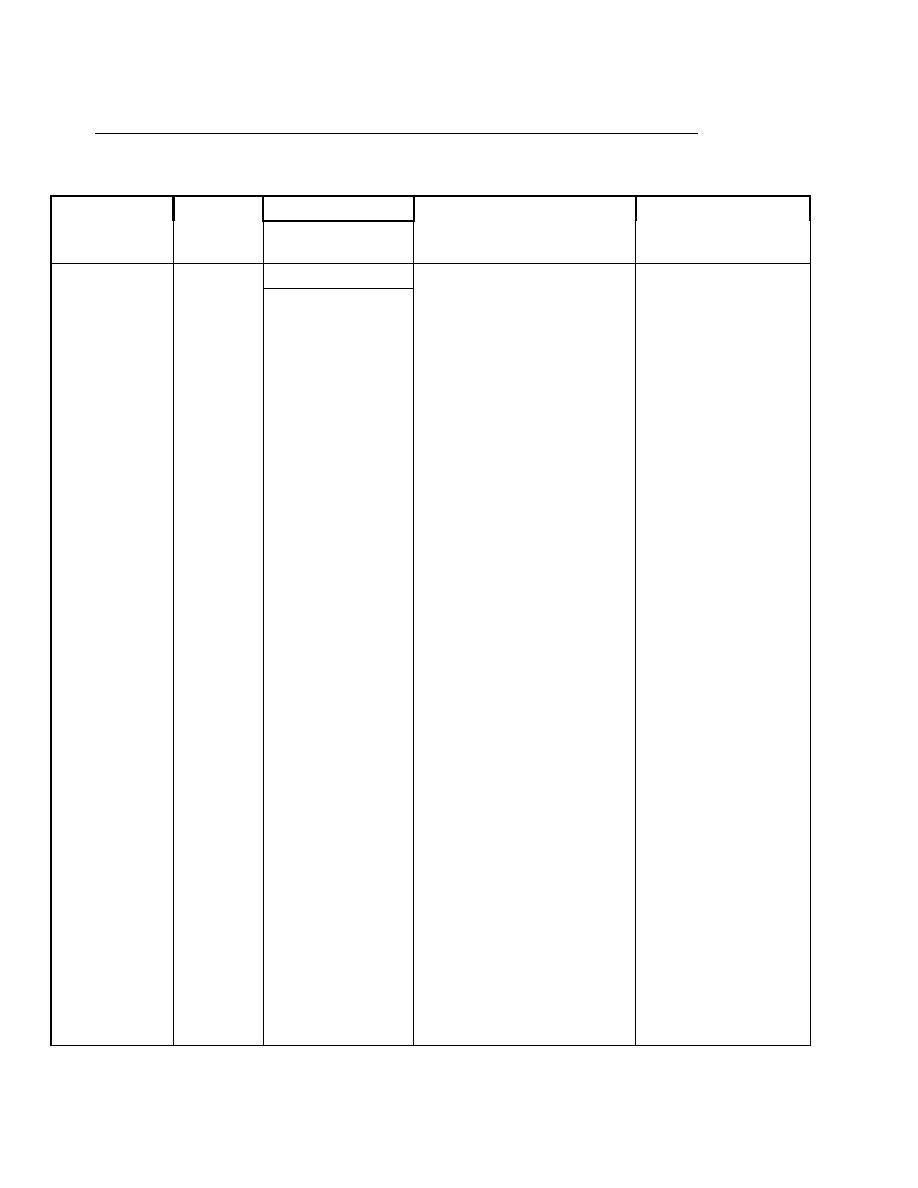

TM 10-5410-228-10

2.21 OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Continued.

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

LMS - interior

42, sheet 5

B

Return air vent

Check for moisture, damaged

Boot damaged or

boot, leaks around boot.

leaking.

43

B

Forward Light Box

Check for loose or missing

Assembly 1A4A5

hardware. Check that lights

are operational.

44

B

Exit/entry door

Check that door operates

Door does not close or

without binding. Check for

open properly. Loose or

loose or missing hardware.

missing hardware

Check seals for damage.

which prevents normal

operation. Damaged

seals.

45

B

Control box

Check for loose or missing

Loose or missing

assembly 1A4A18

hardware. Check that call

hardware which

buttons and buzzer are

prevents normal

operational.

operation.

46

B

Passenger seat belts Check belts for security and

Belts not secure or do

(each side)

proper operation.

not operate properly.

47

B

Passenger chairs

Check for holes, tears or

and back rest (each

excessive wear.

side)

Check hinges for binding and

48

B

Mission Oriented

for loose or missing hardware.

Protective Posture

(MOPP) gear

storage boxes (each

side)

49

B

Rear light box

Check for loose or missing

assembly 1A4A7

hardware. Check that light is

operational.

50

B

Rear control panel

Check for cracked or broken

Loose or missing

1A4A4

gages, indicators and controls.

components/hardware

Check for loose or missing

which prevent normal

hardware. Check gage pointers

operation. Gages cannot

are at zero.

be set to zero.

51

B

Rib pressure gage

Check that set points on gage

Set points cannot be

1A4A4PG1

are set to 1.5 and 2.9 psi.

set. Gage cannot be set

Adjust gage to read zero.

to zero.

52

B

Power mode switch

Check switch for damage

Switch does not operate

1A4A4S1

which prevents normal

properly.

operation.

2-40