TM 10-5410-228-10

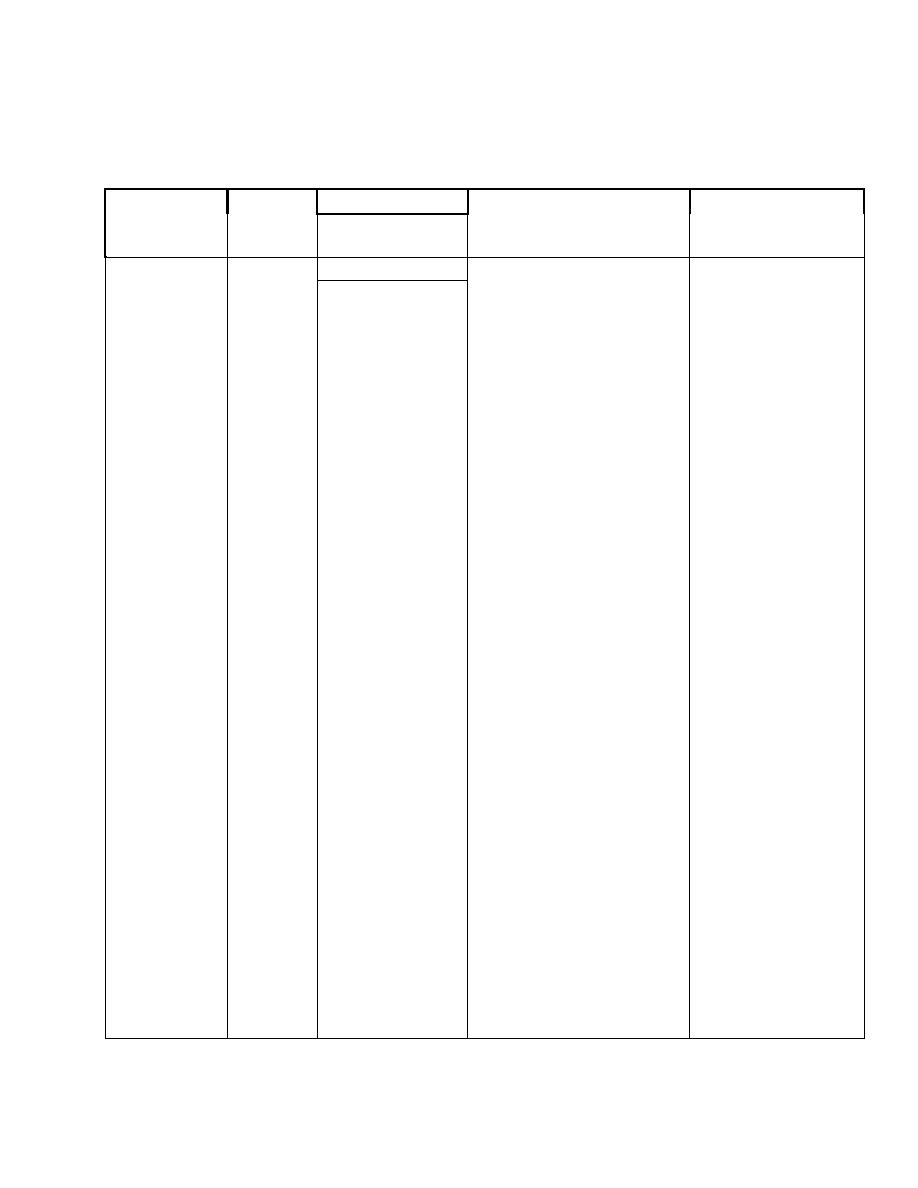

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

LMS - outer

14

B

LMS

Loose or missing

15

B

Antenna and

Check for loose or missing

hardware which

mounting bracket

hardware. Check for cut or

prevents normal

(passenger side)

frayed wiring and loose or

operation.

disconnected connector.

16

B

Window (passenger

Check window for breaks or

Window has hole or is

side)

holes.

broken.

17

B

Relief valve

Check for damage or

Relief valve damaged or

(passenger side)

obstruction.

obstructed (air

shipment only).

18

B

Tailgate/block

Ensure ropes are not frayed

Tailgate cannot be

assembly (each side) and tailgate is raised to

raised or lowered.

stowed position.

ABS not secured.

19

B

Transport cover

Ensure transport cover is

secured. Check for broken or

missing buckles and torn or

frayed fabric.

Loose or missing

20, sheet 2

B

Power panel (driver Check CB for serviceability;

hardware which

side)

covers are on connectors.

prevents normal

Check air inlet screen for

operation.

blockage. Clean as required.

Check for loose or missing

hardware. Check ground

stud for missing wing nut.

Check connectors for broken

pins or corrosion.

21

B

Relief valve (driver

Check for damage or

Relief valve damaged

side)

obstruction.

or obstructed (air

shipment only).

22

B

Window (driver side) Check window for breaks or

Window has hole or is

holes.

broken.

23

B

Steps (driver side)

Check for loose hardware.

Ensure all steps can be

positioned for climbing.

24

B

Compartment

Check for cracks and loose or

guard (driver side)

missing hardware.

25

B

Compartment

Check for accumulation of

(driver side)

fluids, dirt and debris. Clean

as required.

2-37