TM 10-5410-228-10

2.21 OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Continued.

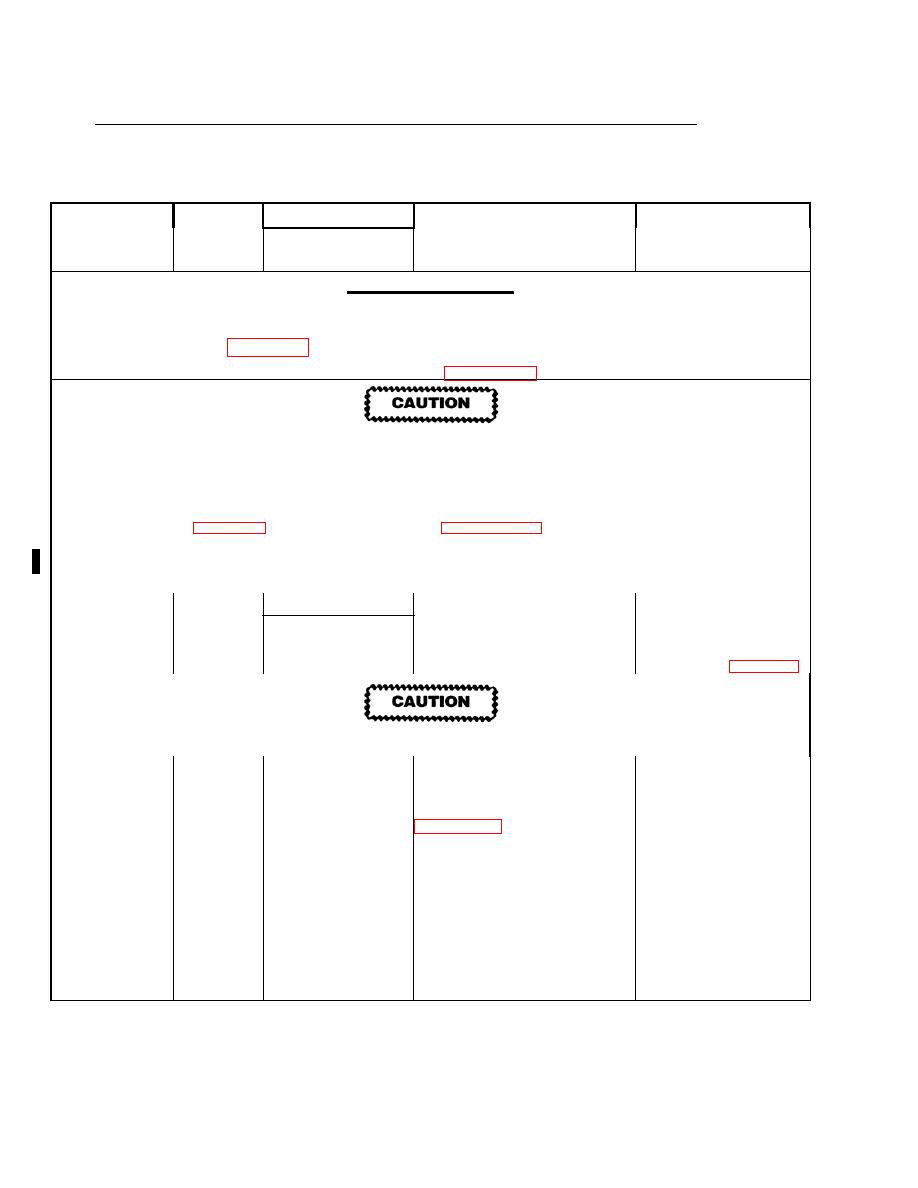

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

OPERATIONAL CHECK

BEFORE operational checks pertain to ECV, LMS, ABS and 10 kW TQG.

Items 62 through 131 pertain to operation of CBPS and should be performed before the

mission. Refer to Figure 2-1, sheets 8 through 12.

Install ECU work platform per para 3.12.1 to check ECU.

To prevent damage to hydraulic pump, EPG switch must be set to OFF before setting ESS

MODE switch to OFF or any mode position.

NOTE

Start ECV per TM 9-2320-387-10. Engage EPG system and perform operational procedures

according to para 2.24. Deploy ABS according to para 2.24.2.2. Check operation of air beam

inflation and CBPS over pressurization (NBC mode). Check heating, cooling and venting

controls and indicators. Allow equipment to operate for a minimum of ten minutes. While

system is operating, check items 62 through 69, sheet 9.

ECU

62, sheet 8

B

ECU

Open doors on ECU and check Damaged hydraulic

for damaged hydraulic

components. Class III

components and leaks.

leak, refer to para 2.20.

Do not mix or substitute any other hydraulic fluid with MIL-H-5606.

63

B

Hydraulic fluid level Check sight gage for fluid

No fluid in sight glass.

level between hot and cold

fill marks. Add fluid per

para 3.12.4.

64

B

Air conditioner

Open door and check level of

Oil level below `MIN' in

compressor sight

oil in sight glass.

sight glass.

glass (COOL mode)

65

B

Wet/dry sight glass Check center of sight glass

Sight glass fluid

(cool mode)

indicator. Colored stud should

changed color to pink.

be blue in color (dry). Check

Bubbles/streaks in R22

for bubbles/streaks in fluid

refrigerant.

flowing through sight glass,

indicating low R22 refrigerant.

2-42

Change 1