TM 10-5410-228-10

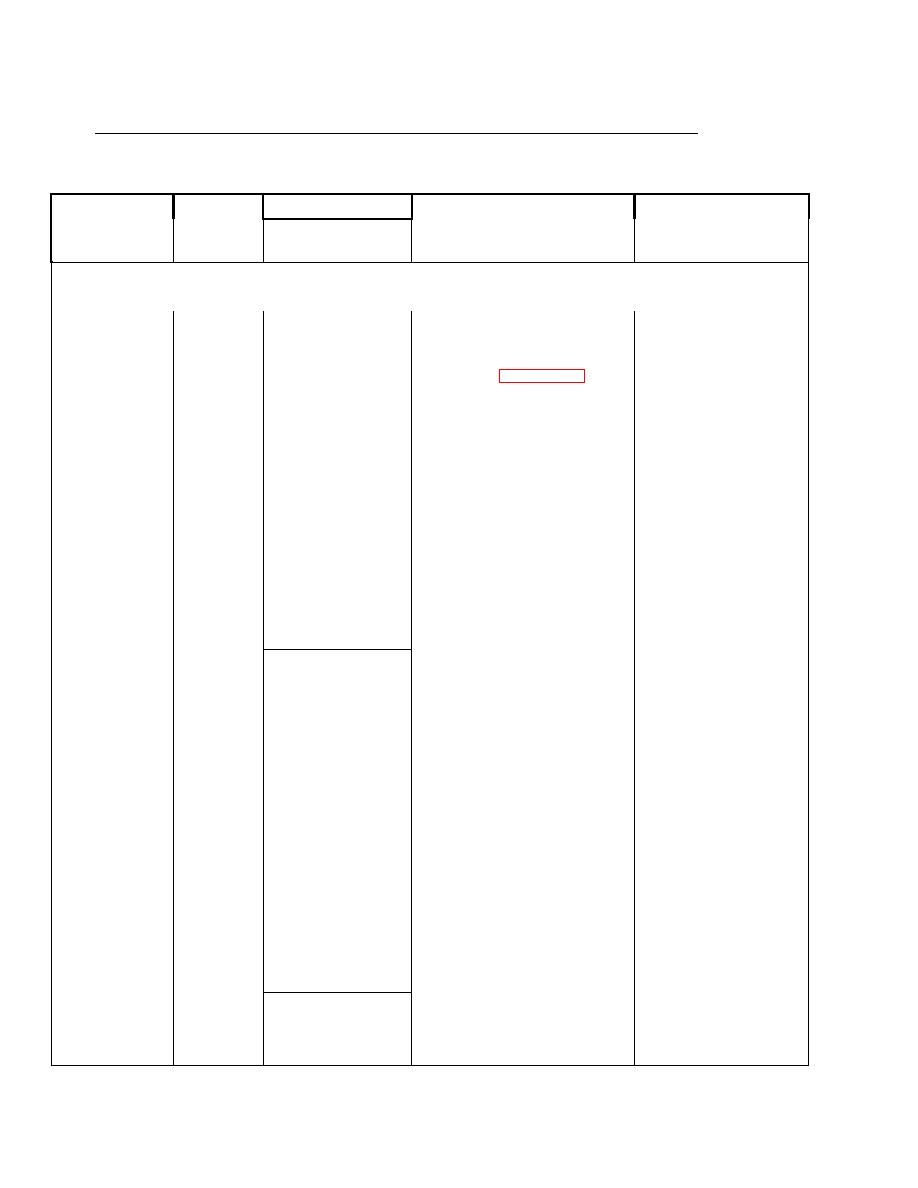

2.21 OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Continued.

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

NOTE

If unit sits in rain or snow, check and drain overflow container as required.

26

B

Hydraulic overflow

Check container for cracks and

container (driver

missing or damaged fasteners.

side compartment)

Check container and empty as

required per para 3.12.3.

27

B

Drain hose (driver

Check hose for kinks and tears

side compartment)

and loose or missing clamps.

Verify that shut off valve is in

closed (horizontal) position.

28

B

Antenna and

Check for loose or missing

Loose or missing

mounting bracket

hardware. Check for cut or

hardware which

(driver side)

frayed wiring and loose or

prevents normal

disconnected connector.

operation.

29

B

Drain tube, clamps

Check for cracks and loose or

and guard (driver

missing hardware.

side)

ECV - inside cab

30, sheet 3

B

EPG control unit

Check wiring harness for

Loose or broken wire.

damage.

31

B

Vehicle control box

Check for loose or missing

Loose or missing

1A4A8

hardware. Check connectors

hardware which

for security. Check that call

prevents normal

buttons and buzzer are

operation.

operational.

32

B

Hydraulic fluid

Check indicators and alarm for Damaged indicators or

level and fluid

damage.

alarm.

alarm indicators/

alarm

33

B

Tachometer/hour

Check for cracked lens and

meter

loose or missing hardware.

Check for cut or frayed wires.

Check wires are connected to

tachometer/hour meter.

ECV - underneath

34

B

EPG magnetic

Check for cut or frayed wires.

Cable is disconnected or

pickup (on flywheel) Check cable is connected to

damaged.

EPG magnetic pickup.

2-38