TM 10-5410-228-10

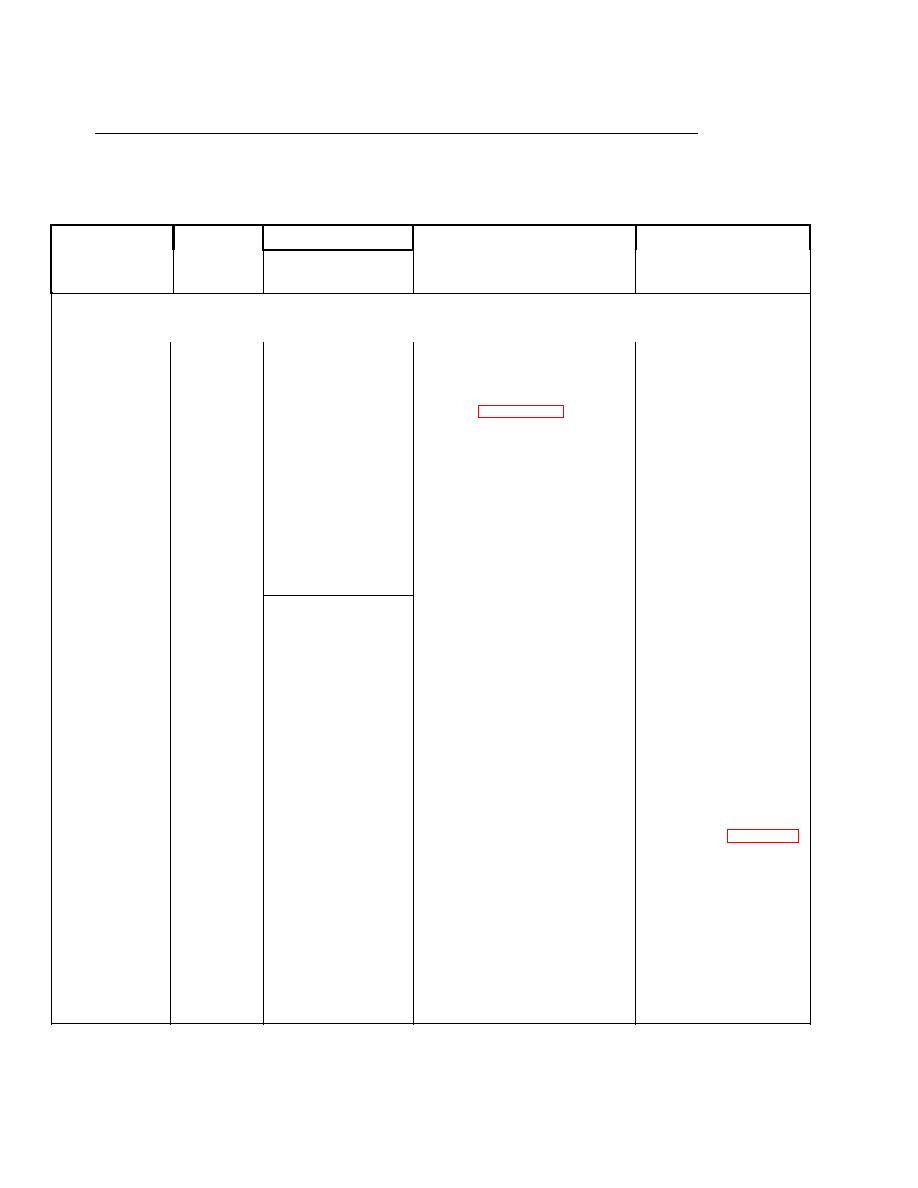

2.21 OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Continued.

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

NOTE

Note direction of airflow arrow on filter when installing.

Filter missing. Missing

6

B

Intake filter screen

Remove access panel and

or damaged gasket.

(passenger side)

check filter for blockage.

Remove all dirt and debris.

Wash per para 3.12.2. Check

gasket.

7

B

Mist eliminator

Check mist eliminator for

Any blockage of air

blockage. Clean as required.

flow.

8

B

Drain tubes, hoses,

Check for cracks or cuts in

clamps and guards

tubes and hoses. Check for

loose or missing hardware and

damaged hose guards.

ECV - passenger

side

9

B

Hydraulic shut off

Ensure hydraulic shut off

Hydraulic handle in

valve (red handle)

handle is in open position (in

closed position.

line with hose).

10

B

Hydraulic shut off

Ensure hydraulic shut off

Hydraulic handle in

valve (in passenger

handle is in open position (in

closed position.

side compartment

line with hose).

red handle)

11

B

Compartment

Check hydraulic lines for

Damaged hoses and

tubing, hoses and

damaged hoses, loose or

loose or missing

fittings

missing hardware, and

hardware which

prevent normal

evidence of leaks.

operation. Class III

leak, refer to para 2.20.

12

B

Auxiliary power

Check motor for signs of

Damaged motor or

pack (in passenger

overheating, discoloration,

connectors. Loose or

side compartment)

cut or frayed wiring, and loose

missing hardware

which prevents normal

or disconnected connectors.

Check for loose or missing

operation.

mounting hardware.

13

Compartment

Check for dirt and debris.

Clean as required.

2-36