(The actual pressure should be at least twice this, to

c. The cartridge case selected for this application

allow for such effects as temperature and friction.) The

is 0.550 inch in diameter; however, the body of the

volume swept by the moving piston is 0.20 X 1.5 or 0.30

thruster cannot be made with an inside diameter small

cubic inch. The initial free volume of the cylinder,

enough to house the cartridge properly and still maintain

taking into account the cartridge retainer, etc., is 0.98

the specified outside diameter without adding

cubic inch. The total final interior volume of the thruster

appreciably to the weight of the assembly. Equally

is then 1.28 cubic inches.

important, if the inside diameter of the thruster was

d. Since the thruster must also supply bypass gas,

made small enough for proper housing of the cartridge,

the initial volume of the device would be decreased and

the charge weight is calculated in two parts. The

the expansion ratio would be increased. For these

minimum charge for thrust is found from figure 22 to be

reasons, the inside diameter of the thruster body is

0.25 gram (550-pound load, lifted 1.5 inches). The

made as large as possible. A cartridge retainer, similar

charge required for bypass can be calculated from

to the type used in initiators, is employed to prevent

equation (51) with suitable interpretation of Pt The

plugging of the bypass port and to prevent shatter of

required pressure at the end of 4 feet of hose is 1,000

propellant at -65F. This retainer fits snugly around the

psi; however, turbulent, high-velocity flow at the bypass

cartridge. The breech is threaded into internal threads

tube entrance will cause loss of pressure to about 70

in the cartridge retainer to hold the cartridge and

percent of the theoretical value, i.e., 1,000 psi is 70

cartridge retainer in place in the assembly. Four slots

percent of Pt. From equation (51), the required charge

are machined in the walls of the cartridge retainer.

is found to be about 1 gram. The total charge, for thrust

These slots permit the walls of the cartridge to rupture

and bypass, then, is approximately 1.25 grams.

and allow the propellant gas to escape while retaining

e. Assume that the ballistician will use H8

the propellant grain in the cartridge.

propellant for the workhorse studies. H8 is suitably

slow-burning, and one grain has adequate size (7/8-inch

long, with 3/8-inch O.D.) to fit the chamber and weight

(2 grams) to approximate the charge. Equation (57)

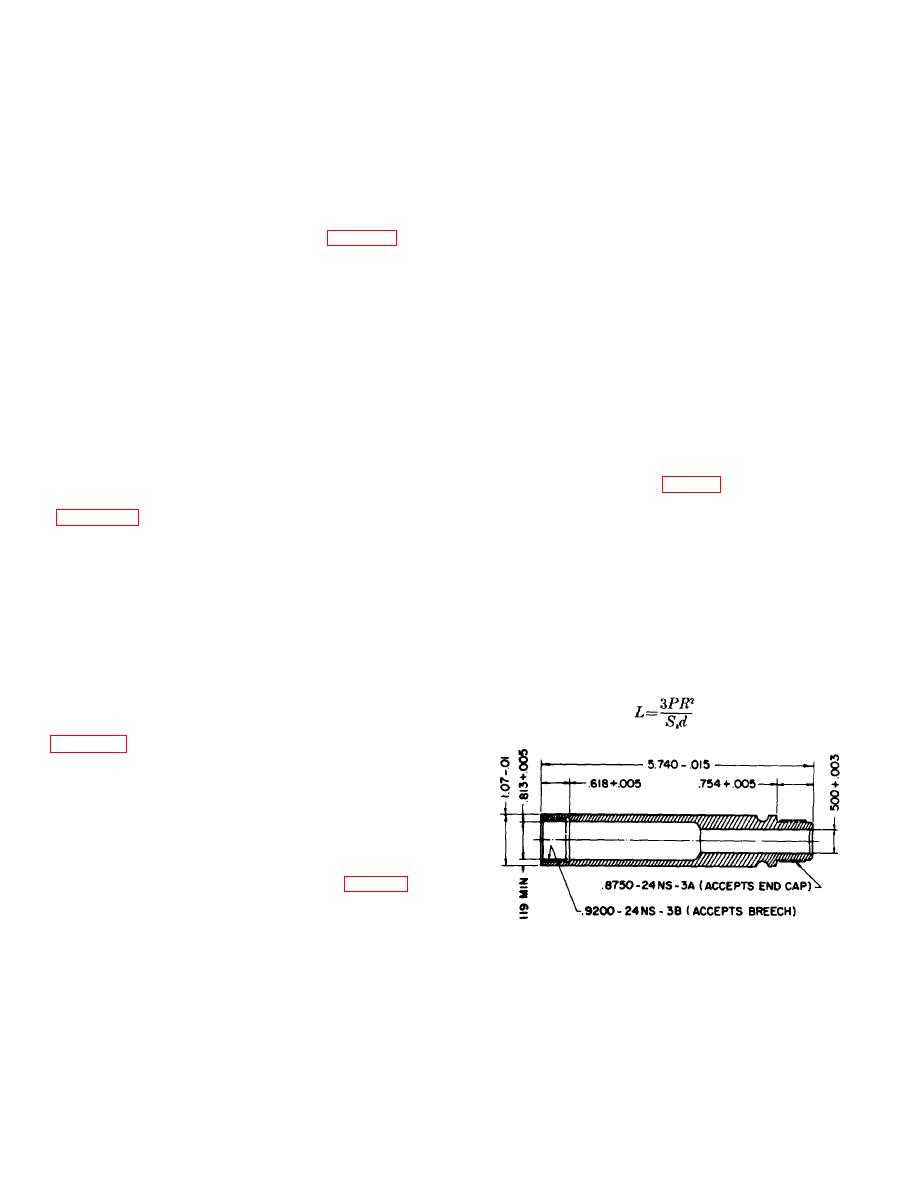

external threads on one end for assembly to the end cap

and internal threads on the other end for assembly to

opening of the bypass port. Using the 2-gram charge

the breech. The body houses the cartridge at the

5

and 1.28-cubic inch chamber volume, with 3.1 x 10 ft-

breech end and houses part of the piston at the other

lb/lb impetus and a B1 value of .45, the chamber

end. The remainder of the piston is housed in the end

pressure, Pt, is about 5,700 psi. Thus, it satisfies the

sleeve.

requirement for a pressure twice the minimum.

b. The maximum pressure which the threaded

(The value of B1 was chosen near the minimum

area (between the end cap and the body) will withstand

because the thruster is small, and the work done

is calculated by using equation (11).

represents only about one-fifth the total charge

(It is assumed that the body will be made of 705T6

requirement.)

aluminum.)

74. Cartridge. a. The cartridge consists of a case

containing the propellant, igniter, primer, and head.

standard cartridge cases is 0.550 inch. This case size is

satisfactory because the igniter will be placed in the

main propellant chamber along with the grain.

(Separate igniter chambers are seldom used with small

cartridges.) The cartridge case selected has a chamber

length of 1 inch.

b. A 72M percussion-type primer is selected for

use with the igniter in the cartridge. (See table IX for

data on this primer.)

Figure 68. Body of thruster.

85