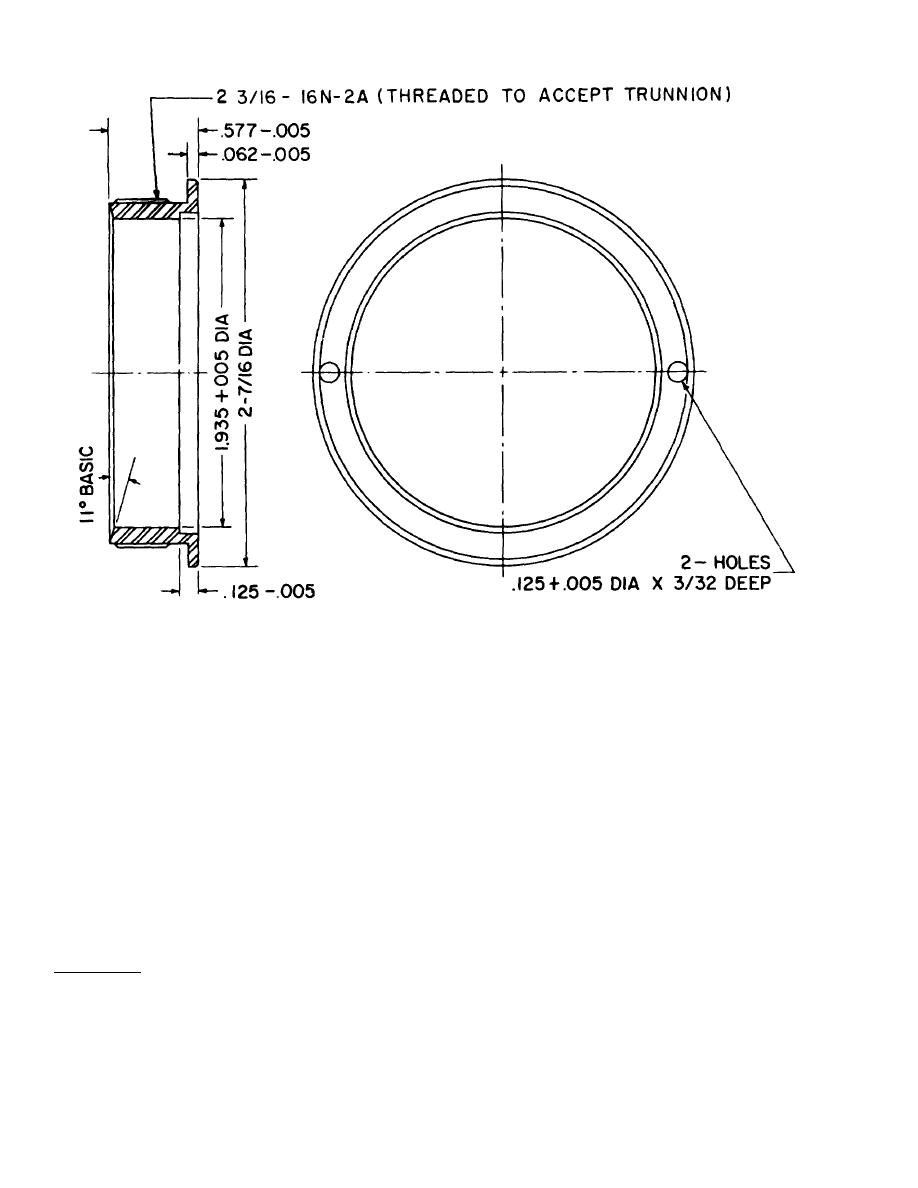

is assembled to the trunnion, the bottom face of the ring

inside the telescoping tube.) If O-ring seals were used,

becomes the upper bearing surface for the latches. A

they might tear as they passed the holes. The seals fit

pair of shallow holes are provided to aid in assembling

in grooves machined in the trunnion and inside tube. A

the ring to the trunnion.

small tab on the spring seal fits into a small hole drilled

in the grooves. The arrangement keeps the seals from

d. The seals used on the ends of the inside tube

rotating in the grooves and threading out of the grooves,

and inside the trunnion are spiral, wound-wire seals.

thereby preventing undesirable friction.

(Wire seals are used because they must pass over holes

in the telescoping tube when the inside tube moves

Section III. M3A1 THRUSTER

the M3A1 thruster are presented below:

70. General. The M3A1 thruster was developed to

release the control column stowage spring and to

Operating temper ..........-65to 160F.†

operate the seat-actuator disconnect in the B52 aircraft

ature range.

escape system.

Stroke ..........................1.5 inches

Firing mechanism .........Gas operated by a 500 psi

71. Design Requirements The design requirements for

min ‡

† At the time of development, devices were not required to function at 200F.

‡ When a device is designed to furnish 500 psi to function the firing mechanism of another propellant actuated

device, it is customary to design it to supply 1,000 psi to insure functioning.

83