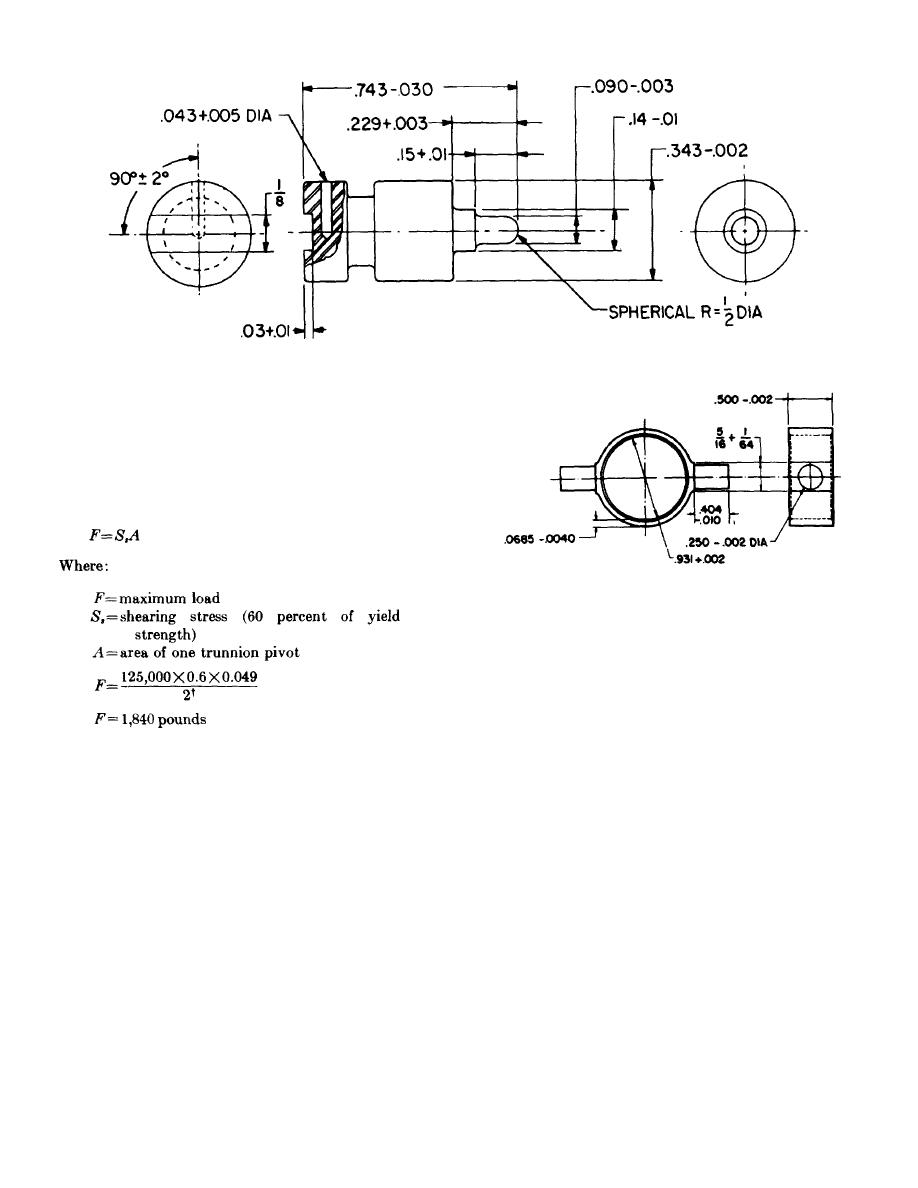

Figure 74. Thruster firing pin.

shearing stresses. Stress concentrations around the

trunnion pivots should be minimized by avoiding sharp

corners where the pivots join the trunnion ring.

c. The trunnion pivots must be strong enough to

permit the full tension load to be applied to the thruster

without deforming or shearing the pivots.

The

maximum load which the 0250-inch-diameter pivots can

withstand is -

Figure 75. Trunnion for thruster.

From this calculation, it is obvious that one pivot can

withstand the maximum load in shear. The trunnion

could also fail by tearing through the ring on both sides

of a pivot. The area which is subject to tearing is:

A =2 X trunnion ring thickness X trunnion width

A-=2 X 0.060 X 0.500

2

A= 0.600 in.

Section IV. M4 INITIATOR

Operating tempera ..............-65to 160F.

82. General. The M4 initiator (Delay-Initiator with

ture range.

Cartridge, Lap Belt Release, M4) was designed to

Envelope:

operate a lap-belt release or other propellant actuated

Maximum

device. The initiator is operated mechanically and

length ...........................6 inches.

contains a 2-second delay element.

Maximum width ................3 inches.

Maximum thick-

83. Design Requirements. The specifications for the

ness .............................2 inches.

M4 initiator include the following performance

Method of operation ............Mechanical, with 20-

requirements and physical characteristics:

to 35-pound pinpull.

† Safety factor of 2 is used for structural member.

90