A = 1.61 X 0.119 = 0.192 in. 2

Assuming the block will be made of aluminum, the

tension load required to tear the male clevis is:

It is obvious from the above calculation that the design

can easily withstand the 2,000-pound tension load

required; therefore, the male clevis part of the block is

designed more than adequately. Aircrewmen worry less

about the apparent strength of the device when

lightening procedures are not used in this section. The

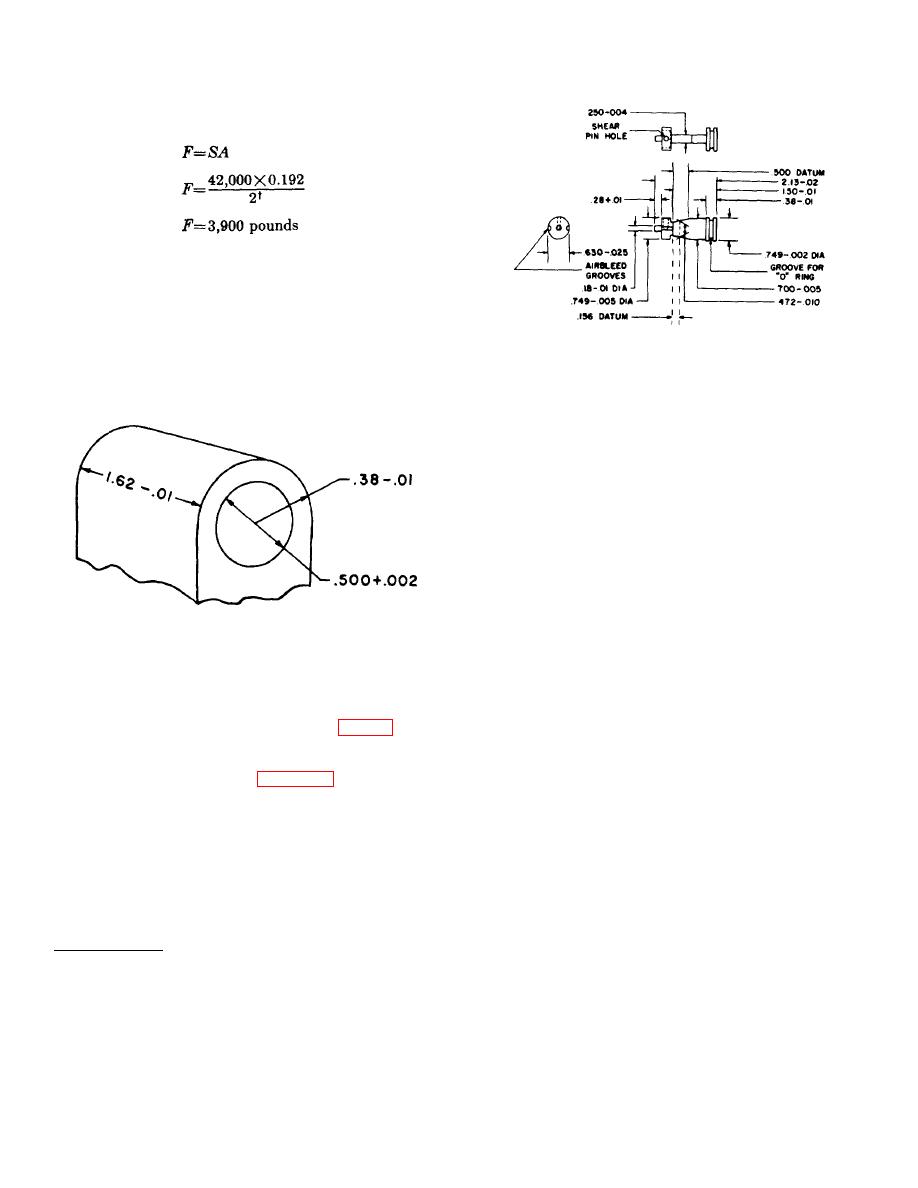

Figure 62. Firing pin for catapult.

walls of the block in the area of the latch slots must be

thick enough to provide sufficient bearing when the

shear pin is used to hold the firing pin in position prior to

tension load is applied. Areas of stress concentration

actuation.

must. be avoided when designing the block.

b. The gas from the initiator must give the firing

pin sufficient kinetic energy to unlock the latches and

actuate the primer. Since the energy supplied to the

primer is equal to the force exerted on the firing pin

times the distance it travels (less losses), the firing pin is

provided with sufficient area to exert the proper force

and sufficient travel to develop the necessary energy to

fire the primer. However, since this firing pin performs a

dual function, the unlatching operation must be

considered. The firing pin travel as -well as the firing

pin itself must be sufficiently long that the camming

angle is not too steep.

Figure 61. Enlarged view of block mounting hole

c. The plug acts as a firing pin guide. The closed

(male clevis).

end of the plug seats against the head of the cartridge to

support the cartridge. A small hole is provided in the

plug to allow the tip of the firing pin to pass through and

66. Firing Mechanism .

to protrude so as to strike the cartridge. The plug not

a. The firing mechanism consists of the firing pin

only supports the head of the cartridge but stops the

and its guide (the plug). The firing pin has cylindrical

forward motion of the firing pin to prevent piercing the

ends and a flat, tapered, center section (fig. 62). The

cartridge primer. The dimensions of the base of the

tapered surfaces are the camming surfaces which move

firing plug must insure the proper protrusion of the firing

the latch toward the center, unlocking the catapult as the

pin.

firing pin is driven forward. Figure 37 illustrates the

shape and action of the firing pin. One cylindrical

d. The size of the shear pin for the firing pin must

section of the firing pin contains a groove into which an

be such that the pin will fail when the gas pressure

O-ring is fitted for sealing purposes. The other circular

develops a force on the firing pin of 220 pounds;

section has a shear pin hole (which is aligned with the

however, it must not fail when the assembled device is

shear pin hole in the block) and air bleed grooves. A

dropped 6 feet onto a concrete slab in three different

copper

positions. The force behind the firing pin is 110 pounds

when 250 psi is applied. In calculating the pin size it

must be realized that there are many variables involved,

and the only way of establishing the actual pin size is

through performance and drop tests.

†2 is the safety factor for structural members.

80