the gas inlet port and exerts pressure on the firing pin.

Bypass require ..............Bypass at end of stroke,

When sufficient pressure is built up behind the firing pin,

ments.

500 psi at end of 4-ft.

the shear pill is sheared and the firing pin is propelled

hose

toward the cartridge, where it strikes the primer. The

Lock requirements ........Initial lock required

primer fires the igniter charge (black powder) which

Thrust

Propel 550-pound weight

ignites the propellant in the cartridge. Propellant gas,

upward through 1.5-

generated by the burning propellant, causes the

inch stroke

cartridge case to rupture. The propellant gas then flows

Structural loads ............800 pounds in tension

into the volume behind the piston. Gas pressure on the

Envelope

Envelope and mounting

piston forces it forward, compressing the spring and

are to remain the same

causing the locking keys through cam action, to move

as those of an earlier

out of the annular groove in the end cap into the piston

thruster, the T3

unlocking groove.

The piston continues to move

Locked-shut .................The thruster shall with-

forward until it contacts the end sleeve. At this point,

stand locked-shut fir-

the piston transmits the force through the end sleeve to

ings without mechani-

the load. As the piston nears the end of its stroke, the

cal failure

O-ring around the piston enters an enlarged section in

No-load ........................The piston shall not

the end cap, permitting propellant gas to escape around

separate from the body

the piston and through the bypass port while the piston

when the thruster is

completes its stroke.

fired without load

73.

First Order Approximations .

a.

Before

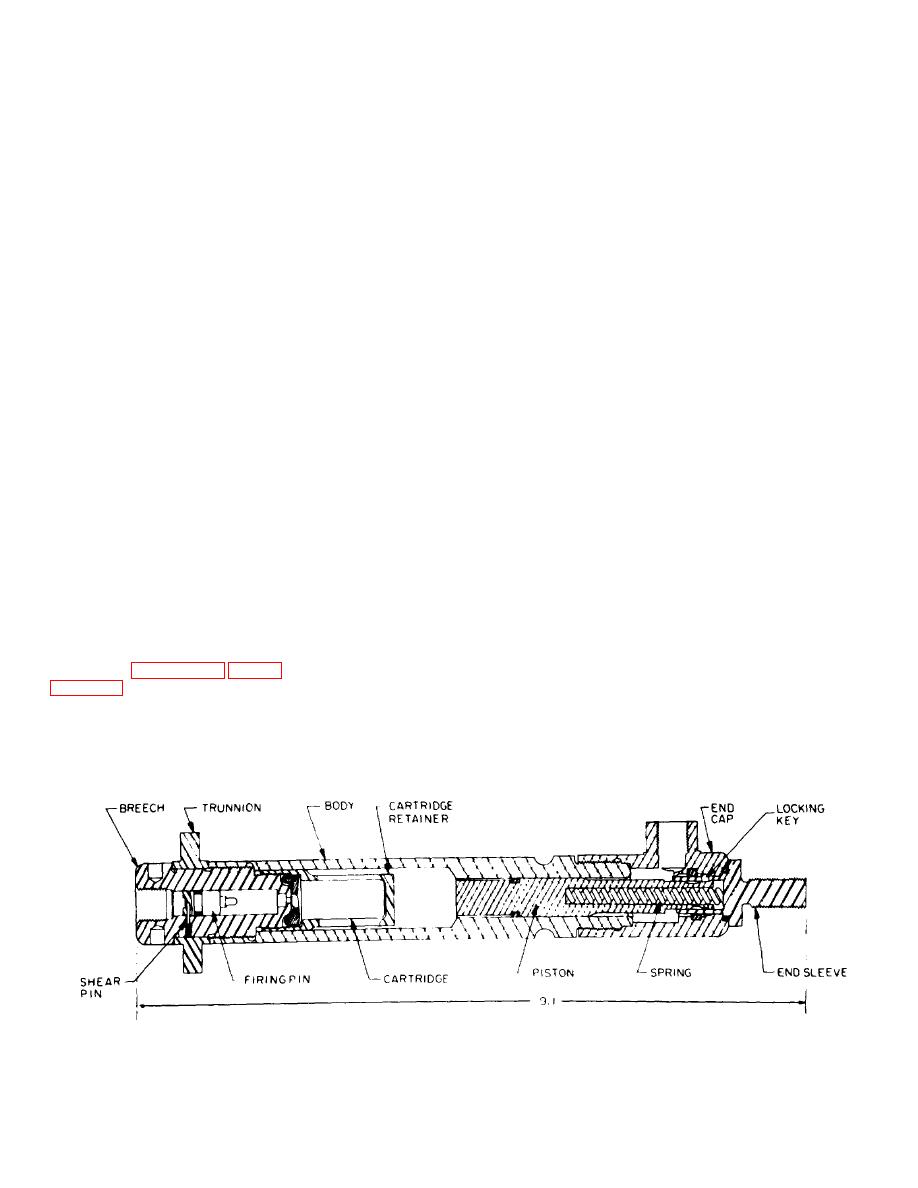

72. Component Layout. a. Since the envelope

workhorse models of the thruster can be fabricated,

dimensions are specified, the stroke is short, and the

using the tentative layout already discussed, the

load to be propelled is light, it is expedient to fit the

propellant charge must be estimated so that a cartridge

necessary components into the envelope and then, with

size can be approximated. The pressure needed to

a better knowledge of the volumes involved, estimate

produce the desired thrust, with the selected piston is

the charge.

used to establish the wall thicknesses and other

b. All components of the thruster may be mounted

component dimensions.

on a single longitudinal axis. A typical gas firing

b. The thruster is designed to supply gas at a

mechanism is fitted to the envelope near the gas entry

pressure of 1,000 psi to a 0.062 cubic-inch chamber at

port. A cartridge, the exact size of which is still

the end of 4 feet of hose after moving a 550-pound

undetermined, is placed in front of the firing mechanism.

weight vertically upward for 1 1/2 inches.

A piston is then fitted in the remaining space in the

envelope. A locking mechanism similar to the one

c. The tentative diameter of the piston is 0.50 inch,

described in paragraph 41 (fig. 36) is fitted in the piston.

with a corresponding area of 0.20 square inch. To raise

the 550-pound load, the minimum pressure required is

operates in the following manner: Propellant gas from

2,750 psi.

an initiator enters

Figure 67. Thruster component layout.

84