(2) If no difficulty is anticipated in staying

within the envelope specified, it may be

advantageous at the start of mechanical

design, to tentatively select a cartridge

case and build the chamber and body

around it. The selection of a case is

based on the volume of the propellant

which it must contain and on its estimated

diameter.

The diameter may be set

provisionally according to the limitations

of final envelope size. Propellant volume

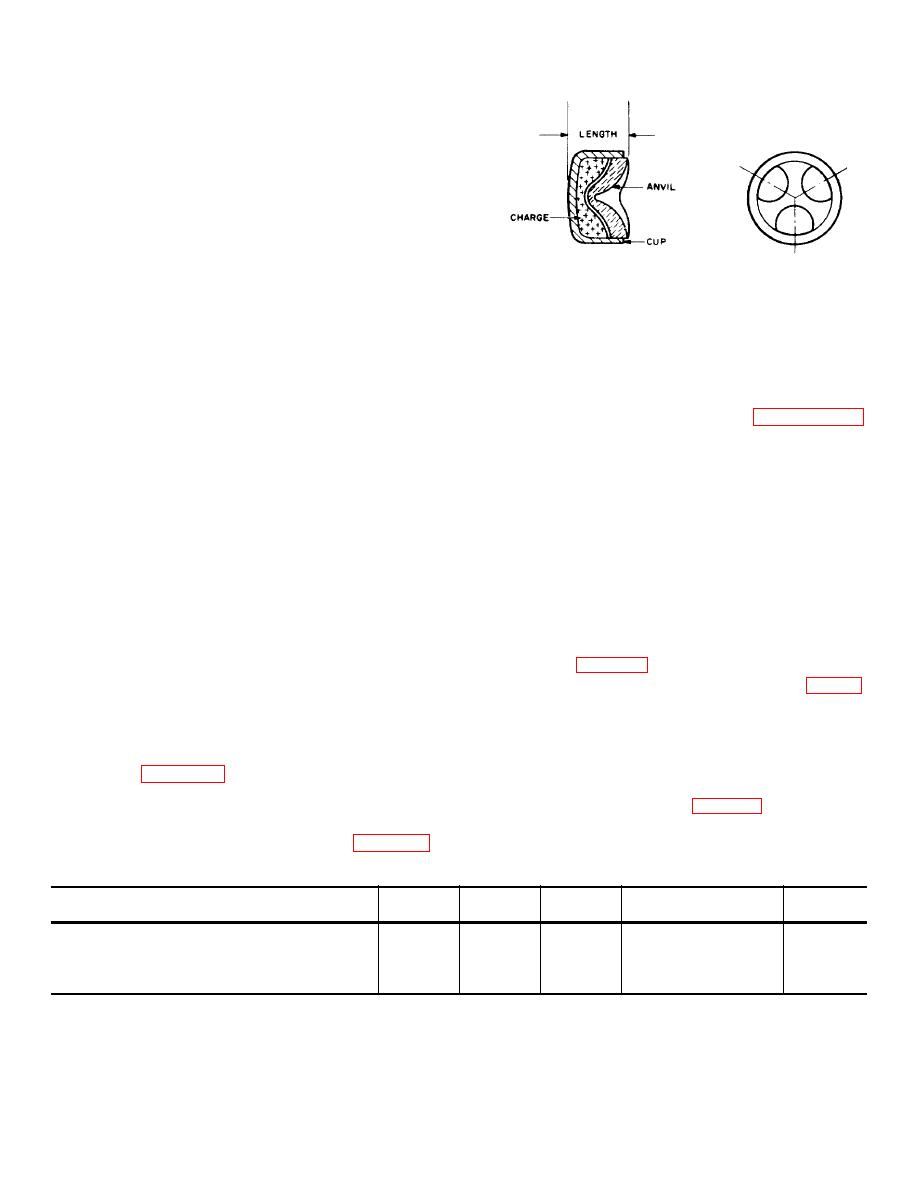

Figure 28. Percussion primer.

may be computed from the propellant

grain dimensions. A propellant density of

(2) The sensitivity of primers, as measured

0.06 pound per cubic inch may be used

by all fire height, which varies from one

with most compositions and large grain

model to another, must be determined in

configurations.

accordance with established test methods.

e. Cartridge Head.

The size of the firing pin and the depth of

indent necessary to fire these percussion

(1) The head of the cartridge, generally made

primers is discussed in paragraph 40,

of aluminum and grooved to accept an O-

firing mechanism.

ring to seal the cartridge, contains a

percussion-type primer or a tapped hole to

e. Cartridge Seals.

accept an electric ignition element. When

(1) The cartridge must be hermetically sealed

a percussion primer is inserted in the

to permit storage for as long as .3 years

center hole of the head, the edges of the

without affecting ballistic performance.

head, adjacent to the primer, are crimped

As previously described, the primer is

to seal the cartridge. In addition, lacquers

separated from the propellant by a thin

or silicone sealants can be used.

web at the base of the cartridge head. An

(2) The base of the cartridge head, under the

O-ring between the head and the cartridge

primer recess, is machined to a thickness

case completes the propellant chamber

between 0.006 and 0.010 inch to insure

seal, and a crimp around the primer

that it will "blow through" when the primer

completes its seal. Methods of testing

fires. Prior to cartridge actuation, this thin

cartridges for leaks are described in

web separates the primer from the

propellant or igniter, since the volatile

(2) The feasibility of a new design (fig. 29)

chemicals of these may desensitize the

which uses extrusion cold-weld seals and

primer mixture if permitted to come in

eliminates all nonmetallic parts of the

contact with it.

cartridge is being studied. This design

d. Primers.

promises to provide a seal far superior to

any now used. Other designs eliminating

(1) Figure 28 shows a typical percussion

nonmetallic parts but relying on lap welds

primer.

The

dimensions

and

are illustrated in figure 30. This continued

compositions of the four primers in

research indicates the importance of

common use in propellant actuated

sealing problems in cartridges.

devices are presented in table IX.

Table IX. Percussion Primers Used in Propellant Actuated Devices

Designation

OD (in.)

Length (in.) Charge weight

Composition

All fire energy

(grains)

(in. oz)

M29A1 .............................................................

0.205

0.115

0.42

5061 Rem .................

18

M42..................................................................

0.170

0.115

0.33

WC #793 ..................

26

72M..................................................................

0.212

0.125

0.55

5061 Rem ................

60

50M..................................................................

0.317

0.225

2.20

5061 Rem ................

120

36