prevent motion of the stroking member before firing.

This function is of special importance in devices

operating against tension loads, since the lock prevents

the piston from extending prior to actuation of the

device.

The two locked sections often act as a

structural element, e.g., to hold the pilot seat in its

position in the plane.

Initial locks also prevent

unintentional separation of the device due to tampering,

vibration or dropping.

b. Final locks are required on some devices to

maintain the piston in the end-of-stroke position,

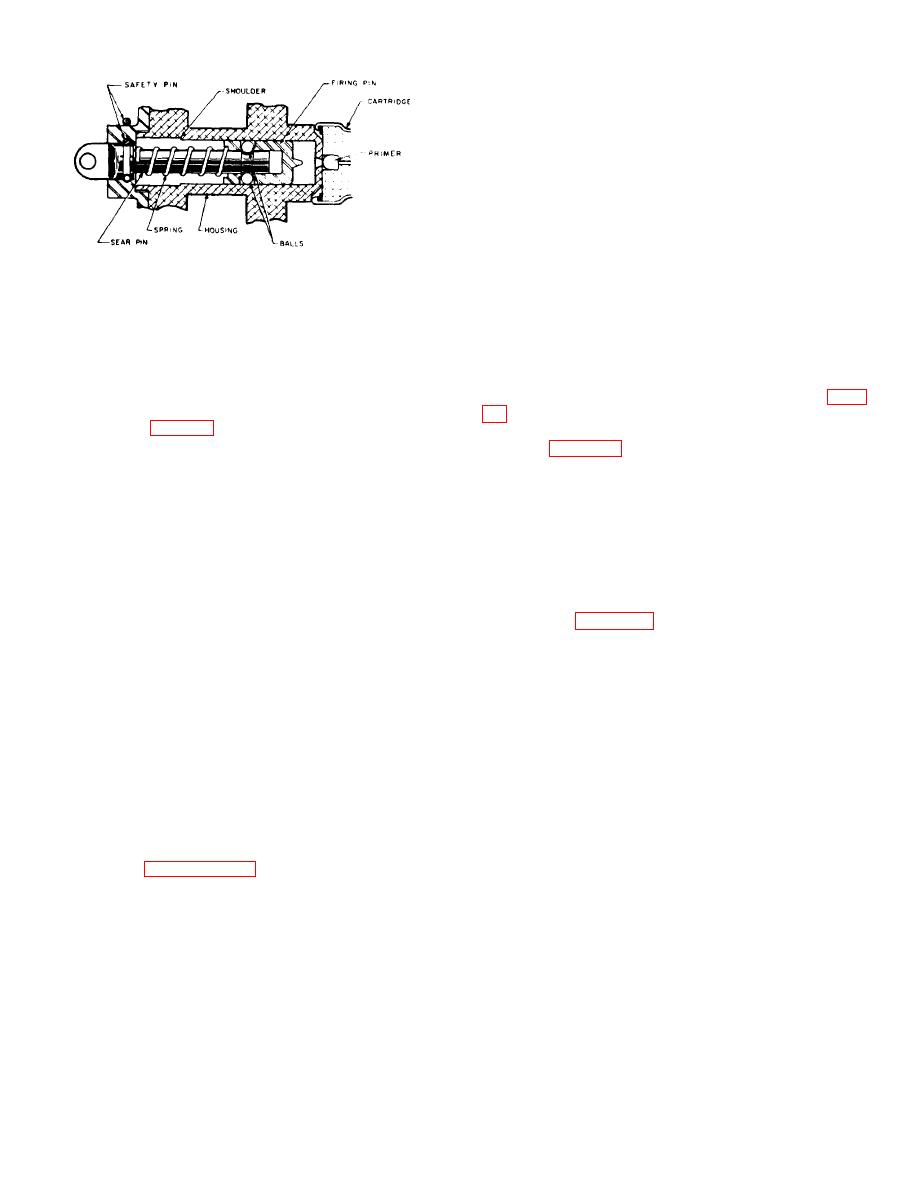

Figure 35. Mechanically operated firing mechanism.

extended or retracted, as the case may be. The final

lock generally is a simple arrangement, consisting of a

(pin) to be disengaged from the firing pin,

snap ring or self locking ball lock which locks into a

and the sear (pin) is withdrawn from the

groove or other depression in the piston.

device. The firing pin then is propelled by

c. While an initial lock requirement may be met by

the compressed spring against the

a simple shear pin or shear ring which locks a piston and

cartridge which contains a percussion

housing together, the problems involved with shear pins

primer.

(covered in this chapter under "Special Problems," para.

(3) The energy required to fire the primer

consideration. A method used in several thrusters is

force and the firing pin travel. The spring

shown in Figure 36. This thruster does not unlock until

is designed to provide several times the

the cartridge fires. When the cartridge fires, gas

all-fire energy of the primer thus providing

pressure forces the piston forward (compressing the

a substantial factor of safety.

spring but not moving the end sleeve) until the four

locking keys drop into a groove in the piston, removing

(4) The selection of spring configurations can

the connection between the housing and the piston. The

best be made by using tables available in

spring keeps the piston in the locked position prior to

spring design handbooks. Such tables

firing. A somewhat similar device is used to lock the

present spring forces and deflection per

tubes of many removers and catapults, except that the

turn for round wire helical springs of

locking keys are released by the firing pin prior to firing

various materials.

the catapult. Figure 37 shows a pair of locking keys

(5) The spring always is kept in a preload

(latches) in position on a firing pin. When gas pressure

position (partially compressed) to insure

is provided behind the firing pin, the pin is propelled

continuous engagement between the

toward the cartridge. As the firing pin moves toward the

spring and the firing pin. This continuous

primer, cam action draws the keys inward, thus freeing

engagement prevents vibration of the

the stroking members.

firing pin when assembled in the device.

d. Design requirements usually list the initial and

Propellant actuated devices are never

final lock requirements from which the size of the

designed with firing pins in the cocked

components involved may be established. The total

position. However, the cocking and firing

shear area and the total area in bearing determine the

of the device is initiated by a single

size of locking keys or locking rings. The emphasis of

operation.

such designs should be on functioning reliability.

(6) The actual procedure followed in

42. Seals. a. Seals in propellant actuated devices

designing a mechanical firing mechanism

perform two important functions: they prevent the entry

may best be seen by referring to

of moisture and dirt during extended storage periods

prior to firing, and they

mechanically

operated

initiator

is

illustrated.

41. Locking Mechanisms. a. Two functional types of

locking mechanisms are used in propellant actuated

devices: initial and final locks. Initial lock mechanisms

41