cartridge end has external threads to which the block is

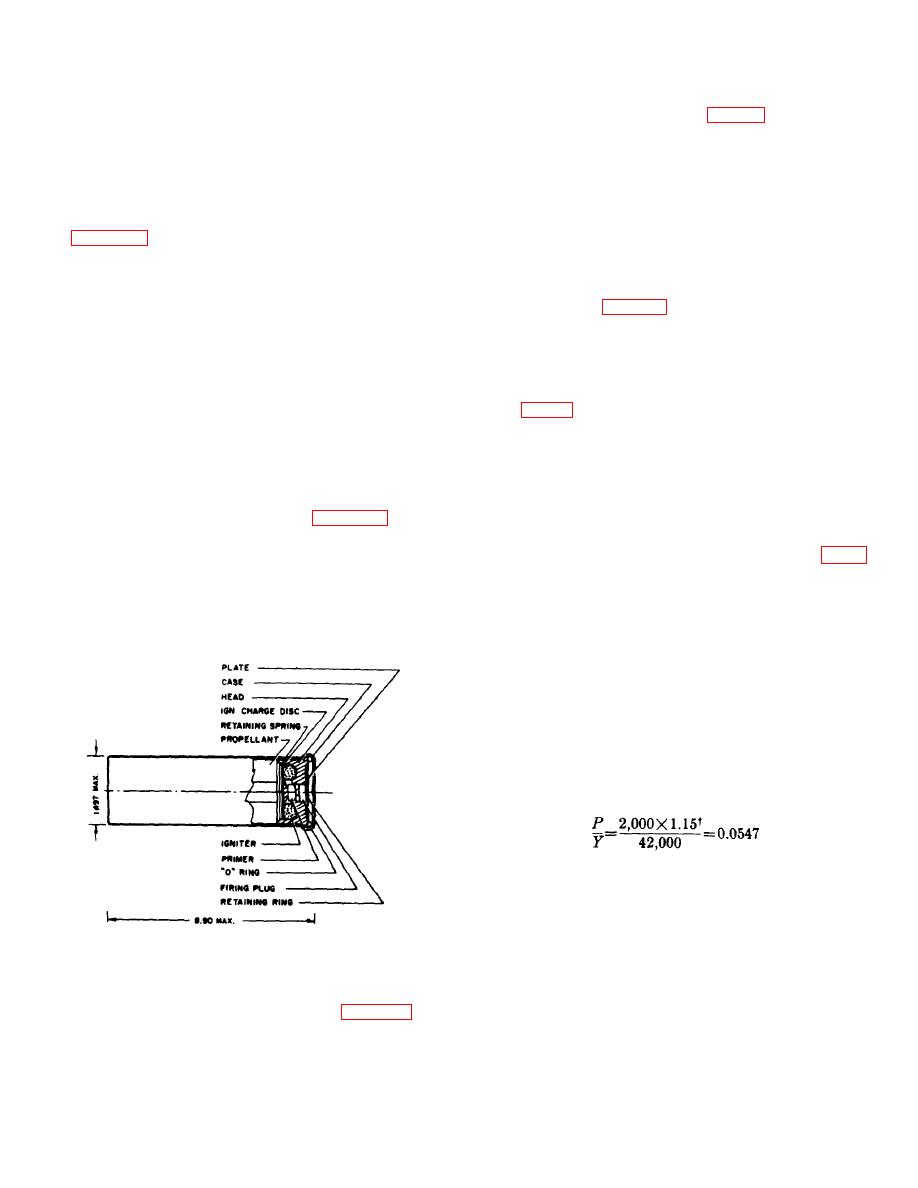

c. A standard head is selected for the cartridge.

attached. The outside surface of the inside tube is

The top of the cartridge head has a shallow, lard

machined, except at the ends (fig. 57) to a slightly

diameter recess which is used to position the retaining

smaller diameter to reduce friction as it strokes. Four

ring, which retains the firing plug and M61 primer. The

slots are machined in the cartridge end of the inside

primer cavity is located in the bottom of the cartridge

tube to provide a means of locking the block to the tube.

head and has sufficient depth to hold the primer and

Three holes in the block provide a locking position (the

firing plug. The igniter is retained in an annular cavity

position where a slot in the tube and a hole in the block

having a semicircular cross section. The approximate

are aligned) every 30

.

igniter charge may be found using the method described

b. The telescoping tube is a long cylinder, the base

in chapter 4. Black powder is commonly used as an

igniter in propellant actuated devices Assuming that 40

of which has a larger outside diameter than the cartridge

grams of black powder are required for each pound of

end. The base is threaded to accommodate the internal

propellant, the igniter charge for the M3 catapult

threads of the spacer. (The functions of the spacer are

cartridge is:

described later in para. 69.) The outside diameter of the

telescoping tube is enlarged for the last 1 inch (at the

spacer end) to act as a stopping shoulder in arresting

0.408 lbρ x 40 gm/lbρ = 16 gm

the motion of the telescoping tube as it approaches the

stopping shoulder of the trunnion. Eight holes are

This charge, as well as the propellant charge, is subject

located around the circumference of the telescoping

to modification during the evaluation program. For

tube (fig. 58) to permit propellant gas to enter the space

example, the M36A1 cartridge uses 65 grains of igniter.

between the telescoping and inside tubes and equalize

d. A disc and retaining spring are provided at the

the pressures within all three tubes.

base of the head to separate the igniter from the

c. The outside tube is a long cylinder with external

propellant. The igniter is retained in the igniter chamber

threads at each end. The cap is used to close the

by a thin magnesium wafer (igniting charge disc) which

bottom end and the trunnion is attached to the top (the

ignites when the igniter burns. Four flash holes connect

cartridge end of the device).

the primer and the igniter chambers. Figure 56 shows

the cartridge has been standardized as the M36.

d. The sizes of the tubes are calculated using the

equation of von Mises-Hencky, which is plotted in figure

63. Tubes. a. The tubes of the catapult act as both the

23. Catapults generally are not designed to withstand

pressure chamber and the stroking members. The

locked-shut pressures; therefore, the peak pressure

inside tube is a long cylinder with grooves on the outside

assumed in the first order approximations (2,000 psi)

of the tube at each end to accommodate wire (tortuous

may be used in the calculations.

path) seals. The

e. It was assumed previously that the inside tube

had a 1l/2-inch inside diameter and 1/8-inch walls (a

standard wall thickness in tubing of this size), while the

telescoping tube had a 13/4-inch inside diameter and

1/8-inch walls. These nominal sizes are used in the

following calculations. The outside diameter of the

inside tube must be large enough to permit grooves to

be machined in each end for insertion of the wire seal.

Assuming that aluminum will be used for the inside tube

to minimize weight, the pressure ratio (P/Y) is:

Figure 56. Catapult Cartridge, M36

† A 1.15 safety factor to used, since this it a cylindrical part which must withstand Internal pressure without rupturing (see

Design Strength considerations, section III, chapter 4).

74