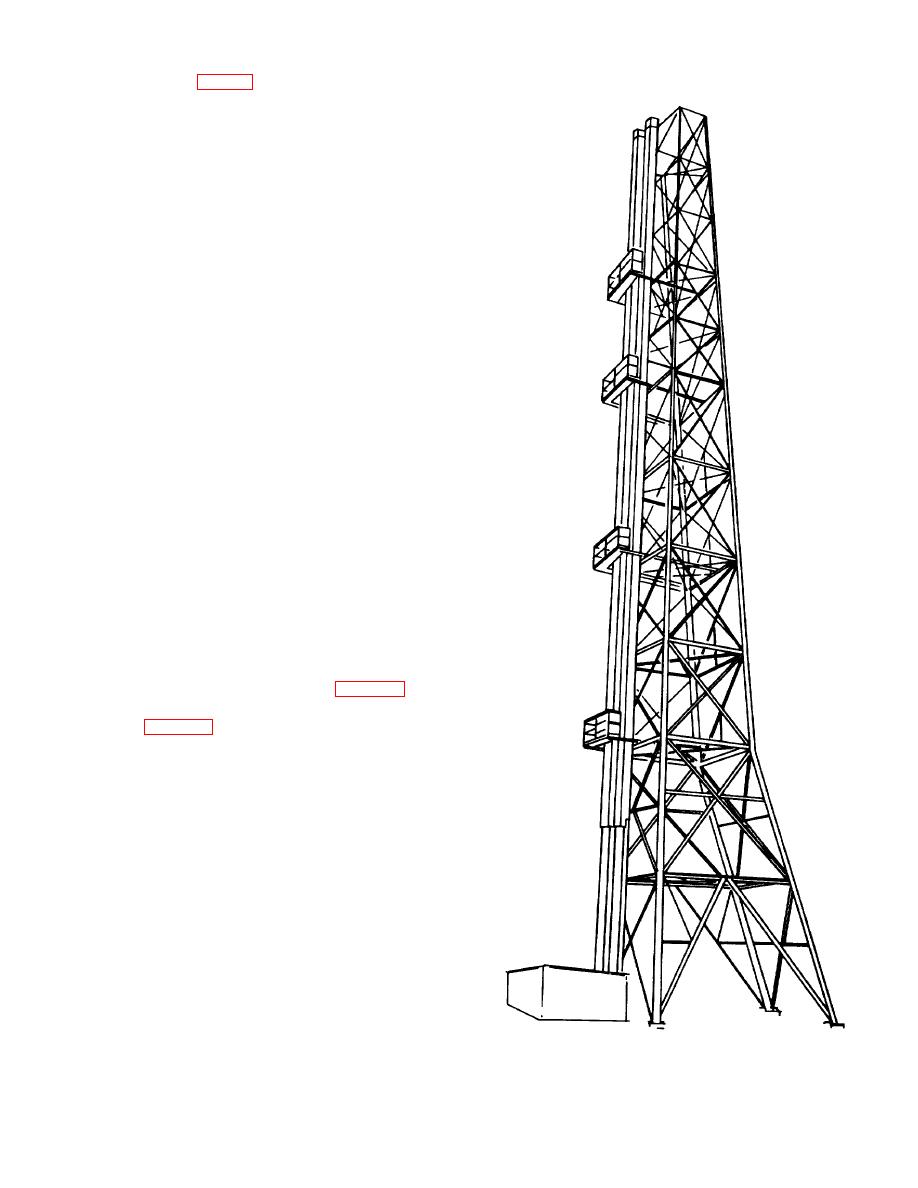

tower (fig. 95) uses a 150-foot vertical

track (comparable to a vertical lathe bed)

on which a carriage travels.

Three

carriages permit a weight range from 60

pounds to 1,200 pounds. One end of the

propellant actuated device is secured to

the base of the tower and the other end is

attached to the carriage.

When the

device strokes, it propels the carriage up

the track. At the 72-foot level, a pair of

brake shoes on the carriage contact rails

and decelerate the carriage. An endless

chain, running the length of the tower, is

normally held fixed but may be driven

upward or downward by an electric motor.

The sprocket on the carriage engages this

chain and by virtue of an included clutch,

may spins freely as the carriage ascends,

but it is prevented from spinning in the

opposite direction; therefore, when the

carriage has reached its maximum height,

it will be held there by the sprocket chain

combination. To lower the carriage, the

chain is driven in the downward direction,

permitting the carriage to fall as rapidly as

the chain descends to its starting place.

The chain may also be driven upward to

raise the carriage for adjusting the

propellant actuated device, under test.

(2) The instrumentation used in tests on the

vertical tower normally includes the

following: a stroke marker and an

accelerometer mounted on the carriage

with

a

quick-disconnect,

and

a

piezoelectric gage, load cell, and a

pressure pickup as shown in figure 96.

(3) Another type of vertical tower is shown in

section of 12-inch ID tubing, supported by

guy struts in two directions. The top of

the tube is capped. There is a large vent

hole at the 15-foot level, and the bottom is

open for installation of the catapult and

instrumentation. The catapult is installed

on a base at the bottom of the tower, and

a weighted piston (simulating the weight

of the canopy or ejection seat and man) is

lowered on the catapult. Upon firing, the

catapult drives the piston up the tube; the

catapult completes its stroke prior to the

tower piston passing the vent hole.

Figure 95. Vertical test tower.

106