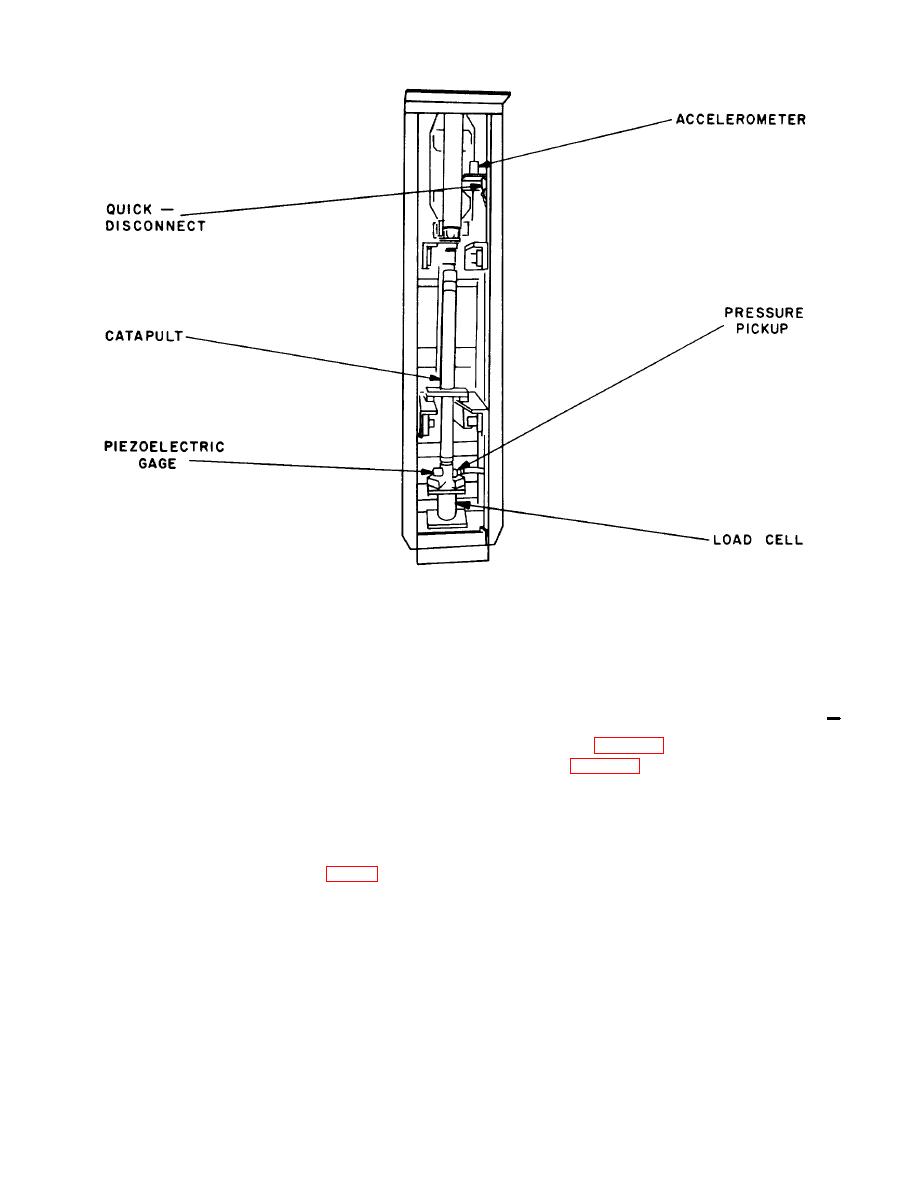

Figure 96. Test tower showing catapult, transducers, and wiring on test track.

be constant. Although many propellant

As the piston continues past the vent

actuated devices (thrusters in particular)

hole, it compresses the air entrapped

operate against varying loads, the load

above it. The compressed air slows the

requirements may be converted into

piston and a spring loaded brake

terms of constant loads for the purpose of

mechanism stops it downward motion

evaluation and development.

The

after stopping.

conversion is possible by estimating Fr as

c. Pressure Cylinders.

in chapter 5.

(1) The vertical tower is effective in testing

(2) Figure 99 illustrates an air cylinder with an

propellant actuated devices with long

inlet at the end farthest from the thruster

strokes and relatively light loads, but

under test and permits injection of air or

many thrusters have short strokes and

gas. This cylinder incorporates an 8-inch

operate against constant loads of

piston (50 square inches) and is used with

thousands of pounds. Pressure cylinders

air pressures as high as 100 psi. Other

were designed to evaluate these thrusters.

cylinders, similar in design to the air

The thruster is positioned (fig. 98) so that

cylinder depicted, use nitrogen instead of

its stroking member moves a piston ill a

air and may be pressurized to 2,000 psi.

cylinder against pressurized air or some

(3) Another model cylinder utilized for testing

other gas. The initial volume of the

thrusters is designed with a double acting

cylinder is so large that the change in

piston which permits air or gas pressure to

volume resulting from the moving piston

be built up on either side of the piston.

is negligible. Therefore, the pressure in

This method allows evaluation of

the cylinder (the load which opposes the

motion of the thruster) can be assumed to

107