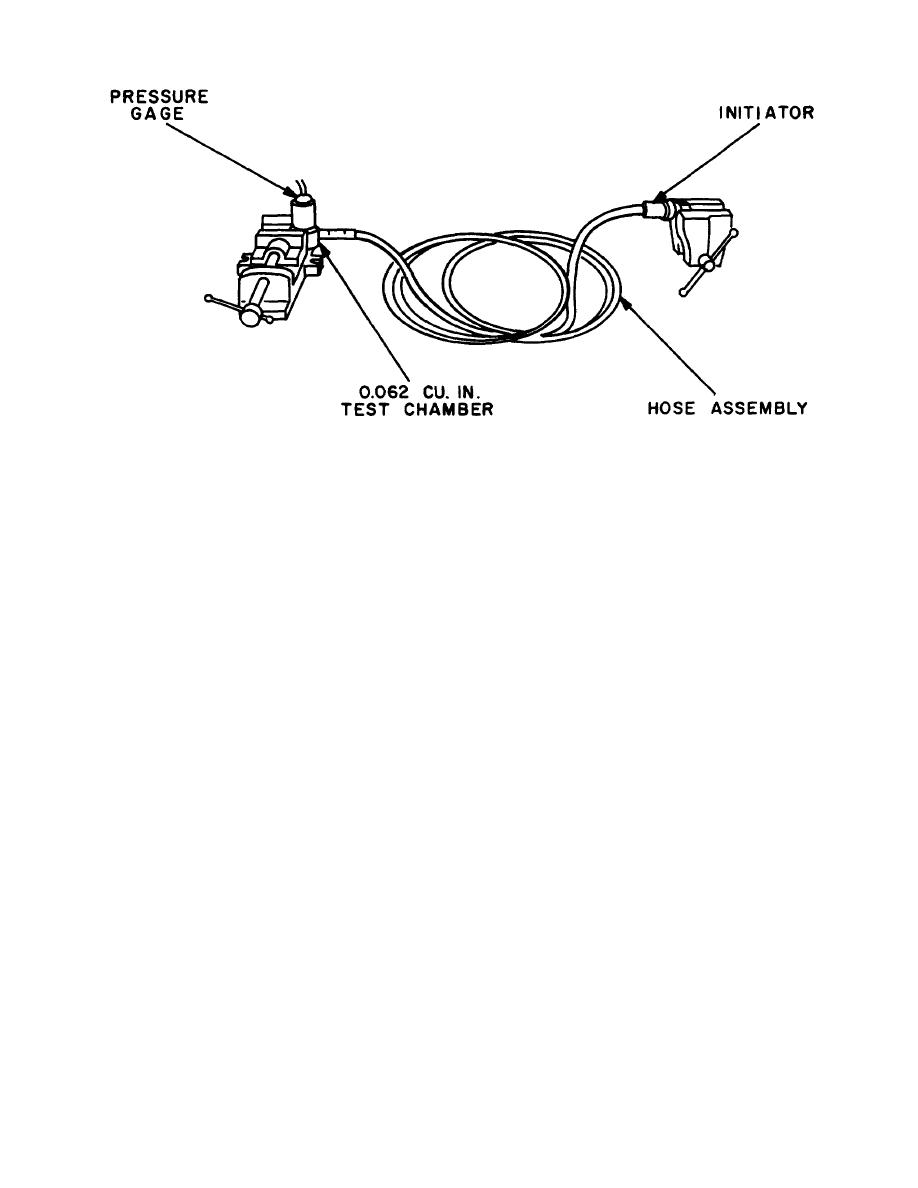

Figure 101. Teat setup for initiators.

controlled pressure of the Krypton gas causes

recorded so that, in the event of malfunction or

radioactive gas to flow through any leakage paths.

failure, the units may be checked against their

Cartridges that have leaked contain radioactive gas and

original dimensions. All cartridges should be X-

emit small amounts of gamma radiation. The radiation

rayed to ascertain proper assembly of primer

is measured, which indicates the amount of material that

components.

has leaked into the cartridge. This process detects leak

(3) The firings which must be conducted and the

rates so small it would take an undetected leak

characteristics which must be recorded are

thousands of years to leak one cubic inch of air into an

determined by the design requirements. The

evacuated chamber.

following ballistic firing program is typical,

This test also may be used to test small propellant

except when a device contains a component or

actuated devices for leaks.

subassembly that is identical to one that is a

part of an already standardized device; then all

95. Development Evaluation Program. a. General.

or a portion of the ballistic firings may be waived

(1) During the development program, newly

by agreement with user.

designed propellant actuated devices are

b. Workhorse Model Evaluation.

evaluated to insure that they meet design

(1 Workhorse models are used to develop the

requirements.

Workhorse models, strong

charge, determine the locked-shut pressure, and

enough to stand repeated firings, are fabricated

check the general operation. The workhorse

from design drawings. These workhorse models

model may include provisions for measuring

are fired to develop the proper charge and to

characteristics which may not be measured in

assure the feasibility of the design. After charge

later models; for example, it may be designed to

development and the elimination of weaknesses

accept pressure pickups or piezoelectric gages

in design through firings and modification of the

to record internal pressure.

workhorse models, several prototype models

(2) Normally, the following test program is utilized.

are fabricated and evaluated.

Workhorse models are fired at 70 F. to

(2) Prior to development firings, it is important that

establish the propellant charge. A minimum of

all devices be given a 100 percent inspection

three rounds are fired

and the dimensions

110