TM 10-5410-228-10

2.21 OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Continued.

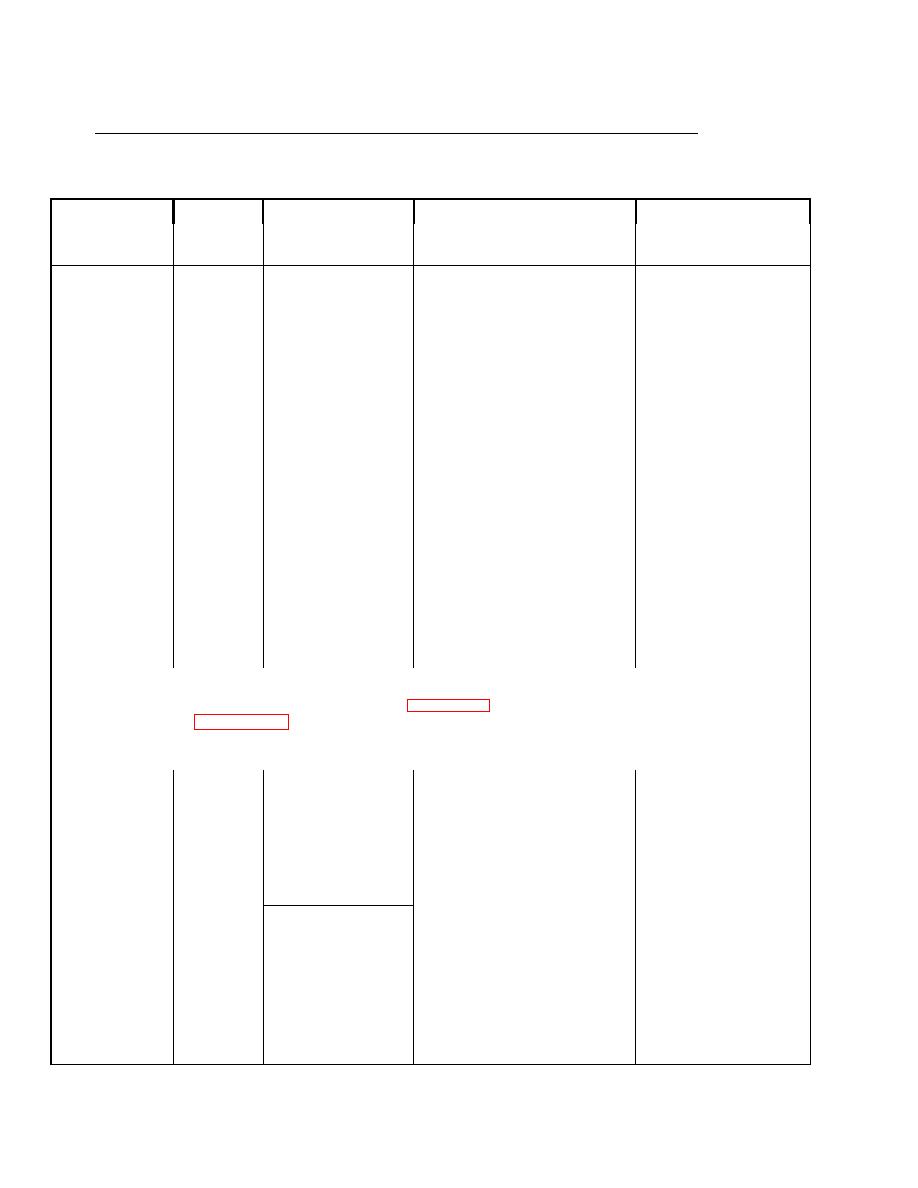

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

116

B

Receptacle panel

Check for loose or missing

Loose or missing

(rear)

hardware. Ensure receptacle

hardware which

panel is functioning properly.

prevents normal

operation.

Cover or housing is

117, sheet 12

B

Recirculation Filter a. Check cover (118), housing

dented, cracked or will

(119), and fan impeller blades

not mate properly;

(120) for dents, cracks and

cracked or loose fan

loose fit.

impeller blades.

Cable has bare wires,

b. Checked electric cable (121)

broken connector or

for bare wires, broken

damaged connector

connector (122) or damaged

pins.

connector pins (123).

c. Check for broken or

ON/OFF switch

damaged ON/OFF switch

damaged or broken.

(124).

d. Remove cover (118) by

Filter element is

releasing four link-lock

missing, punctured or

fasteners (125). Pull filter

water damaged.

element (126) up and check for

punctures or water damage.

NOTE

Shut off ECV and deflate ABS according to para 2.24.3. Deploy ABS using 10 kW TQG

according to para 2.24.2.3. Check operation of air beam inflation and CBPS over

pressurization (NBC mode). Check heating, cooling and venting controls and indicators.

While system is operating, check items 127 through 131, sheet 11.

127, sheet 11

B

Power panel (driver Check air inlet screen for

Loose or missing

side, rear)

blockage. Clean as required.

hardware which

Check for loose or missing

prevent normal

operation. Power panel

hardware. Ensure power panel

is functioning properly.

does not function

properly.

HMT

Damaged power cable

128

10 kW TQG

Ensure power cable and

or connector.

ground lead are connected

and connectors are secure.

Check for damage.

129

B

10 kW TQG

Perform operator's PMCS per

TM 9-6115-642-10.

ECV - outer

(passenger side)

2-48