TM 10-5410-228-10

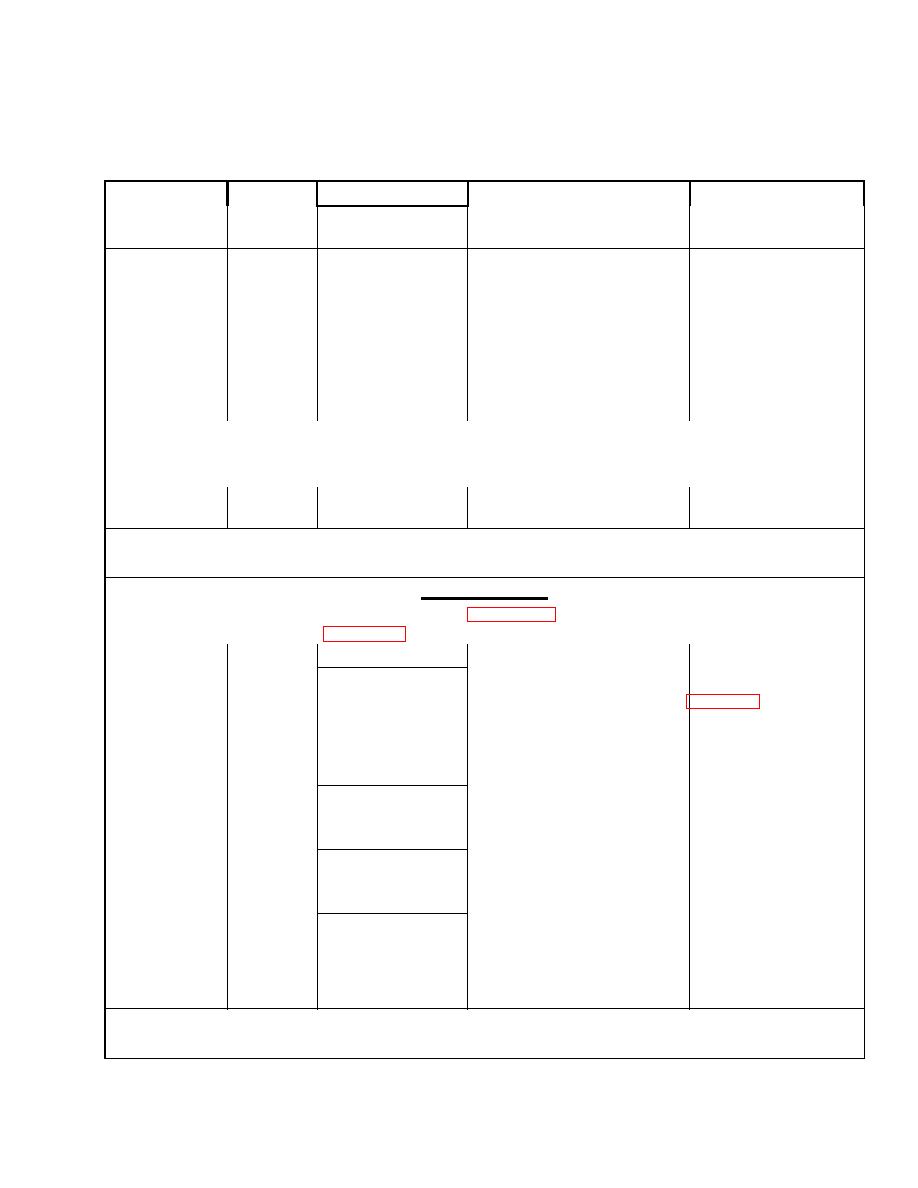

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

105

D

TALP airlock door

Ensure door and adjustable

Door cannot be opened

or closed. Loose or

(inner)

vents open and close and can

be secured. Ensure retaining

missing hardware

clamp and latch function

which prevent normal

properly. Check for loose or

operation.

missing hardware.

106

D

TALP airlock side

Ensure zipper is closed.

Zipper broken or

jammed in open

position.

NOTE

The function of recirculation filter is to filter out residual toxic gases that may have entered

the ABS through entry/exits and by off-gassing from clothing.

117

D

Recirculation Filter Check that recirculation filter Recirculation filter does

operates.

not operate.

NOTE

This ends the during mission operational (static) checks.

AFTER STRIKING

The following is accomplished after striking (para 2.24.3) and when CBPS system is ready to

return to unit. Refer to Figure 2-1, sheets 1, 6 and 7.

ECV - under hood

1, sheet 1

A

Primary hydraulic

Check for leaks and loose or

Class III leak; refer to

pump hoses and

missing hardware.

para 2.20. Loose or

fittings

missing hardware

which prevents normal

operation.

ECU

6

A

Intake filter screen

Check intake filter screen for

Any blockage of air

blockage. Check for leaks.

flow.

LMS

56, sheet 6

A

Straps (each side

Ensure all straps are

and roof)

secured.

HMT

60, sheet 7

A

HMT hookup

Ensure light cable, breakaway Hookup components are

chain and safety chains are

not secured.

connected securely to ECV and

pintle hook is secured with

safety pin.

NOTE

This ends after striking checks.

2-51