TM 10-5410-228-10

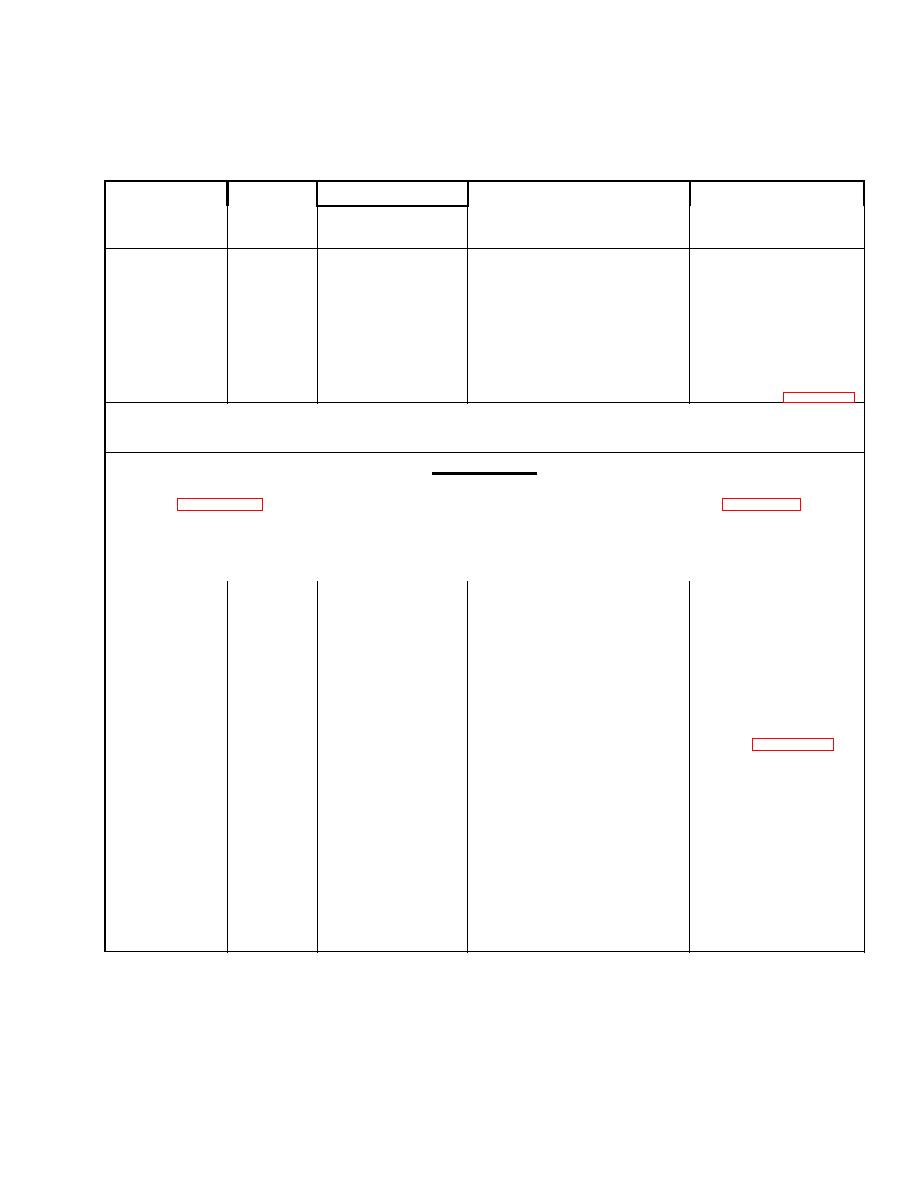

Table 2-1. Operator Preventive Maintenance Checks and Services for CBPS - Continued

B - BEFORE D - DURING A - AFTER H - HOURLY

Location

Item

Item to

Not Fully Mission

No.

Interval

Check/Service

Procedure

Capable If:

130

B

Auxiliary power

Check pump and motor

Pump or motor does

pack A2M1/P2 (in

function properly.

not function properly.

compartment)

131

B

Compartment

Lift cover and check for

Loose or missing

tubing, hoses and

leaks and loose or missing

hardware which

fittings

hardware.

prevent normal

operation. Class III

leak, refer to para 2.20.

NOTE

This ends the before mission operational mode checks.

STATIC MODE

The following items pertain to CBPS when operating in static mode. ABS deployed according

to para 2.24.2, using power from ECV (EPG system ON) or 10 kW TQG. Refer to Figure 2-1,

sheets 7 through 11.

NOTE

Check items 39, 89 through 106 and 117, sheet 9, when using internal power (ECV).

Low on fuel; gage shows

H (4)

Fuel tank (gage)

Check fuel gage on cab

1/4 tank of fuel.

instrument panel every four

hours; fill fuel tank per

standard operating

procedures.

39

H (72)

NBC filter

Check reading on NBC filter

Differential pressure

differential gage.

across the NBC filters

is greater than 9 iwg

(refer to para 3.12.5).

89

B

Rib pressure gage

Check reading on gage.

Gage does not read

between 1.5 psi and 2.9

psi.

90

D

Rear control panel

Ensure the following indicator Indicators are

lights are not illuminated.

illuminated.

91

D

DANGER HYD OIL Check indicator.

HYD OVERHEAT

TEMP indicator

indicator illuminated

(red).

92

D

NBC FAN indicator Check indicator.

PRES LOW indicator

illuminated (red).

2-49