38. Body and Chamber. a. Gas-Generating Devices.

usually is possible to reduce the bending

stresses which occur at the junction of the

(1) The body of a propellant actuated device

cylinder and each closed end by using a

is the enveloping member or housing, and

thick end section and suitable fillets. This

the chamber houses the cartridge. In

is discussed in detail in chapter 6. The

simple propellant actuated devices, such

stresses occurring in gas-generating

as initiators, the body serves as a

devices are triaxial because a longitudinal

chamber as well as the housing.

stress is introduced by the partially or fully

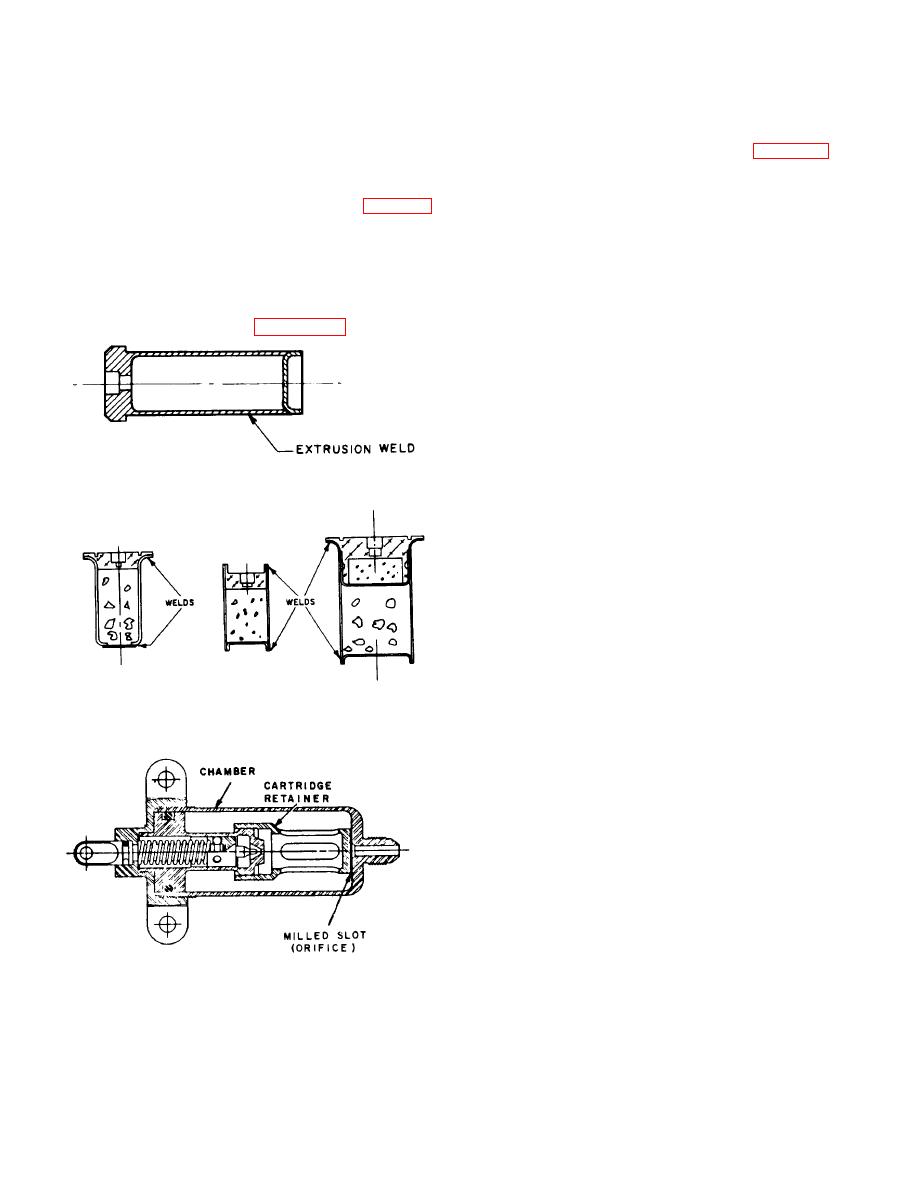

(2) One type of initiator is shown in figure 31.

closed ends.

The cylindrical shape is chosen because it

(3) In some initiators, the cartridge must be

is easy to fabricate.

The physical

supported by a cartridge retainer, since

dimensions are either specified or are

the chamber acts as the body and is

functions of the necessary internal

considerably larger than the cartridge. Tie

volume. Wall thickness is a function of

cartridge retainer fits over the cartridge. It

internal pressure and is calculated as

is cylindrical in shape and has a series of

shown earlier in paragraph 31. It

slots machined in its walls to permit the

cartridge walls to "blow-through" when the

propellant is ignited. The slots in the

retainer serve to contain the burning

propellant and prevent the propellant

grains from being thrown against the

chamber walls and shattered. The base

of the cartridge retainer fits over the exit

Figure 29. Cold welded cartridge

port of the initiator forming a filter. A

series of milled slots in the base of the

cartridge retainer permits the generated

gas to flow through the exit port while

preventing small burning particles of

propellant from passing into the hose or

tubing. Miniature initiators use the body

or chamber as a cartridge retainer and

insert a small filter at the exit port to

prevent the escape of small particles of

propellant. The holes in the filter or the

slots under the cartridge retainer should

have areas which exceed the area of the

Figure 30. Feasible configuration of cartridges with

exit port to prevent their functioning as

lap welds (cold weld type).

flow-restricting orifices.

b. Stroking Devices.

(1) The body design of stroking devices is

similar to that of gas generators, except

that greater strains occur in the absence

of longitudinal stress (undamped-type

stroking devices are subject to biaxial

stresses). In addition, the wall thickness

of the body must not only contain the

internal pressure, but act as a structural

member.

(2) The increase in diameter with pressure

and its effect on sliding fits in the stroking

members must be considered.

In a

Figure 31. Initiator with cartridge retainer.

thruster, the stresses also are complicated

37