32. Length of Thread Engagement. After calculating

the tubing size necessary to withstand the stresses

be used to determine the maximum permissible

involved, the second most important calculations are

pressure when the tube size is specified. For example,

those for determining the length of engagement of

the maximum pressure permissible with a tube whose

threads. Threads are designed in accordance with

dimensions are 1.500 outside diameter and 1.248 inside

Bureau of Standards specifications. The length of these

diameter may be found as follows:

threads may be calculated by using equation (11). (The

derivation of equation (11) is given in appendix III.)

Assuming that there are triaxial stresses, P/Y=0.170 is

obtained from the tables in appendix II. If the material is

Where:

steel with a value of Y=125,000 psi, then P=0.1770 X

L=length of engagement of threads

125,000 =21,250 psi.

P=maximum internal pressure

e. Conversely, the maximum pressure could have

S3=shear strength

been estimated and the wall ratio taken from the table of

R=major radius of female (max)

d=minor diameter of male (min)

the envelope drawing, the necessary ID can be

This equation includes a 1.5 safety factor to allow for

calculated. The tubing size specified in the military

tolerances and the distribution of stresses within the

standards most closely approximating these dimensions

engagement.

would be used.

Section IV. DESIGN PROCEDURES

33. General. a. Typical procedures are presented here

which, with some variations, are used in the design of

propellant actuated devices. The procedures have

arbitrarily been divided into three categories: gas-

generating devices, stroking devices, and (multi-device)

systems. The design of special purpose devices (such

as cable cutters and gas operated trigger mechanisms)

is similar to that of gas-generating and stroking devices,

so it was not considered necessary to discuss these

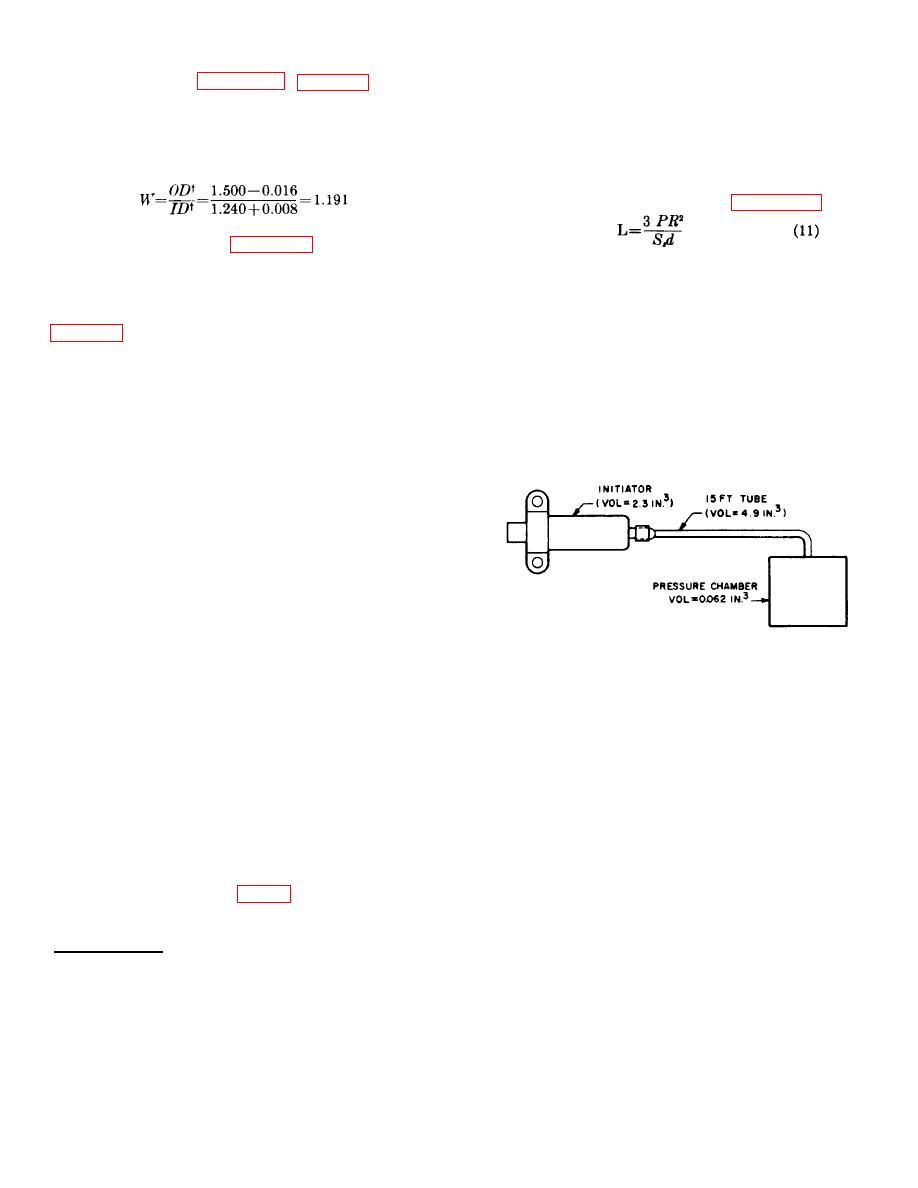

Figure 24. Simple PAD system using an initiator.

separately.

b. The discussion of systems, unlike those for the

b. The ballistician uses these three values to

gas-generating and stroking devices, does not present

estimate the propellant charge necessary to produce the

design procedures, but rather presents material on how

required pressure. The method of estimating this

systems are established and their reliability maintained.

pressure is described in the ballistics design discussion

34.

Gas-Generating Devices.

a.

The design

(chap. 5). The designer then calculates the maximum

requirements for gas-generating devices specify the

pressure which may be developed in the initiator when

pressure that is to be generated and where it is to be

the device is fired "locked shut." (The chamber is closed

measured. For example, an initiator may be required to

so that the internal volume of the chamber must contain

produce a pressure of 500 psi in an 0.062-cubic-inch

all of the gas generated by the burning propellant.) The

chamber at the end of a 15-foot tube. Using the

strength of the walls is calculated from the "locked shut"

envelope specified, the designer estimates the internal

pressure, using the curves or tables described

volume of the initiator, the volume of the tubing to be

previously.

used, and the volume of the chamber in which the

c. To estimate the locked-shut pressure, the "gas

pressure is to be measured (fig. 24).

law" is approximated as shown below:

† The smallest possible OD and largest possible ID are used. The numbers 0.016 and 0.008 are tolerances.

32