sometimes a military requirement: e.g., thrusters.) The

decision on the damper is based on the estimated stroke

time and required velocity or acceleration. Damper

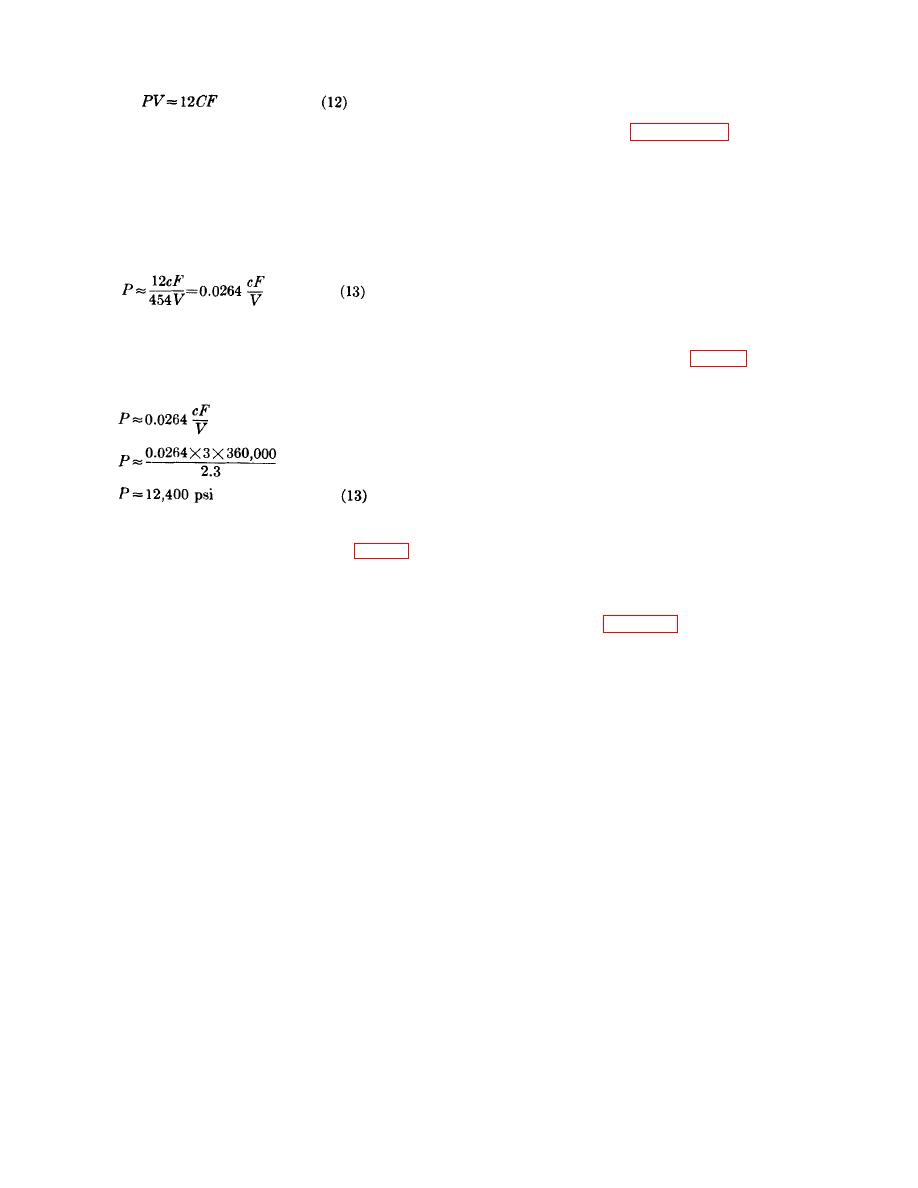

Where:

design is discussed in paragraph 45.

P=maximum gas pressure (psi)

b. The next consideration is the envelope of the

V=volume (in.3)

stroking device. The envelope dimensions may be

C=charge weight (lb)

specified with a complete drawing or only a few

F=the impetus of the propellant (ft-lb/lb)

maximum dimensions may be given. In the latter case,

The factor 12 is used to permit the use of inch units in

the designer determines all dimensions. The designer

the gas law.

Rewriting equation (12) using the

now positions the trunnions on the envelope according

equivalents indicated, and introducing a factor (454) to

to the eventual installation of the device. (The purpose

permit the charge to be given in grams, yields

of using trunnions for mounting is to permit self

alignment; and thus avoid bending loads in stroking

devices.) With all of the above completed, it is then

d. To illustrate the use of this equation, assume an

determined whether the envelope will permit the

initiator is to be designed with an internal volume of 2.3

necessary stroke. Thrusters have been developed with

cubic inches. The ballistician determines that 3 grams

as many as 3 moving tubes (fig. 25) to reconcile the

of propellant of F=360,000 ft-lb/lb is required. Applying

necessary stroke with the specified envelope.

equation (13),

c. It is now possible to compute the initial volume

(available to the powder gases) and the final volume

(the volume at end of stroke or where the tubes

separate) and determine the expansion ratio. The

expansion ratio of a device is the ratio of the final

volume to the original volume. It is customary in

propellant actuated devices to limit the expansion ratio

Since the maximum pressure which can be produced is

to 3 to 1, although several devices have had ratios

12,400 psi, this value and the value of Y corresponding

greater than 4 to 1.

to the material may be used in the curve (fig. 23) to

d. In an effort to enlarge the initial volume of a

determine the wall ratio and, therefore, the thickness of

device (and therefore reduce the expansion ratio), many

the wall.

devices are designed with holes in the walls of the inside

e. It is common practice to fabricate the first model

tubes to permit gas to flow around the tubes as well as

of a device (workhorse model) out of steel and to make

within the tubes. Figure 25 shows a thruster with this

it considerably stronger than necessary so that the

design feature. Gas flowing outside as well as within the

operation of the device and the actual pressures which

tubes also eliminates large pressure differentials and

are generated can be studied. This workhorse model

permits the inside tube walls to be made thinner and

also permits repeated firings whereas the final product,

lighter.

in most cases, is designed as a one-shot item.

e. Ballistics, in conjunction with the design, now

Considerable fabrication cost and time may be saved by

determines the charge and cartridge sizes necessary.

the liberal use of removable portions on original test

These determinations are critical for devices using

models of propellant actuated devices. These portions

pyrotechnic delay elements, since the delay elements

can be removed and modified without necessitating

must fit inside the cartridge case with the propellant.

redesign of the complete device.

The maximum pressure to be developed is also

35. Stroking Devices. a. The design procedure for

determined. If the device is to bypass pressure at the

stroking devices is more complex than that for gas

end of stroke, it must be insured that sufficient energy

generators. After the design requirements have been

remains in the device after completing its stroke to

examined and the stroke length and stroke time

permit the proper energy bypass.

approximated, it must be decided whether to use an

f. The next step is to fit a firing mechanism to the

open or a closed system and whether or not to use a

device and design the individual components. Any

damper to control the stroke. (A closed system is

changes in design that are necessary are made, and a

33