TM 10-5410-228-24

This task covers:

a. Removal/Disassembly

b. Assembly/Installation

INITIAL SETUP

Equipment Conditions:

Tools/Test Equipment:

Shop Equipment, Automotive Maintenance and

Power shut off. Power panel and rear control panel

Repair (Item 38, Appendix B)

tagged.

Gloves (Item 16, Appendix B)

Hydraulic system drained (see para 2.14.3).

Goggles (Item 17, Appendix B)

LMS guard removed (see para 2.13.15).

11/16 Inch Crowfoot Wrench (Item 53, Appendix B)

ABS inflation air hose disconnected

13/16 Inch Crowfoot Wrench (Item 54, Appendix B)

(see para 2.13.7).

15/16 Inch Crowfoot Wrench (Item 55, Appendix B)

Sound guard removed as required (see para 3.9.2).

Torque Wrench (Item 66, Appendix B)

Materials/Parts: (Cont.)

Materials/Parts:

Two O-rings (Item 57, Appendix E)

O-ring (Item 55, Appendix E)

Hydraulic Fluid (Item 24, Appendix C)

O-ring (Item 56, Appendix E)

Rubber Gloves (Item 25, Appendix C)

O-ring (Item 62, Appendix E)

Wiping Rags (Item 39, Appendix C)

Sealant (Item 46, Appendix C)

Four Lockwashers (Item 19, Appendix E)

Two O-rings (Item 63, Appendix E)

NOTE

A small amount of hydraulic fluid will be released when removing tubes. Collect fluid in cup

or small container and clean any spillage with rags.

Remove/disassemble only to the extent necessary to remove or replace defective

assemblies/components. Use standard maintenance shop practices/procedures.

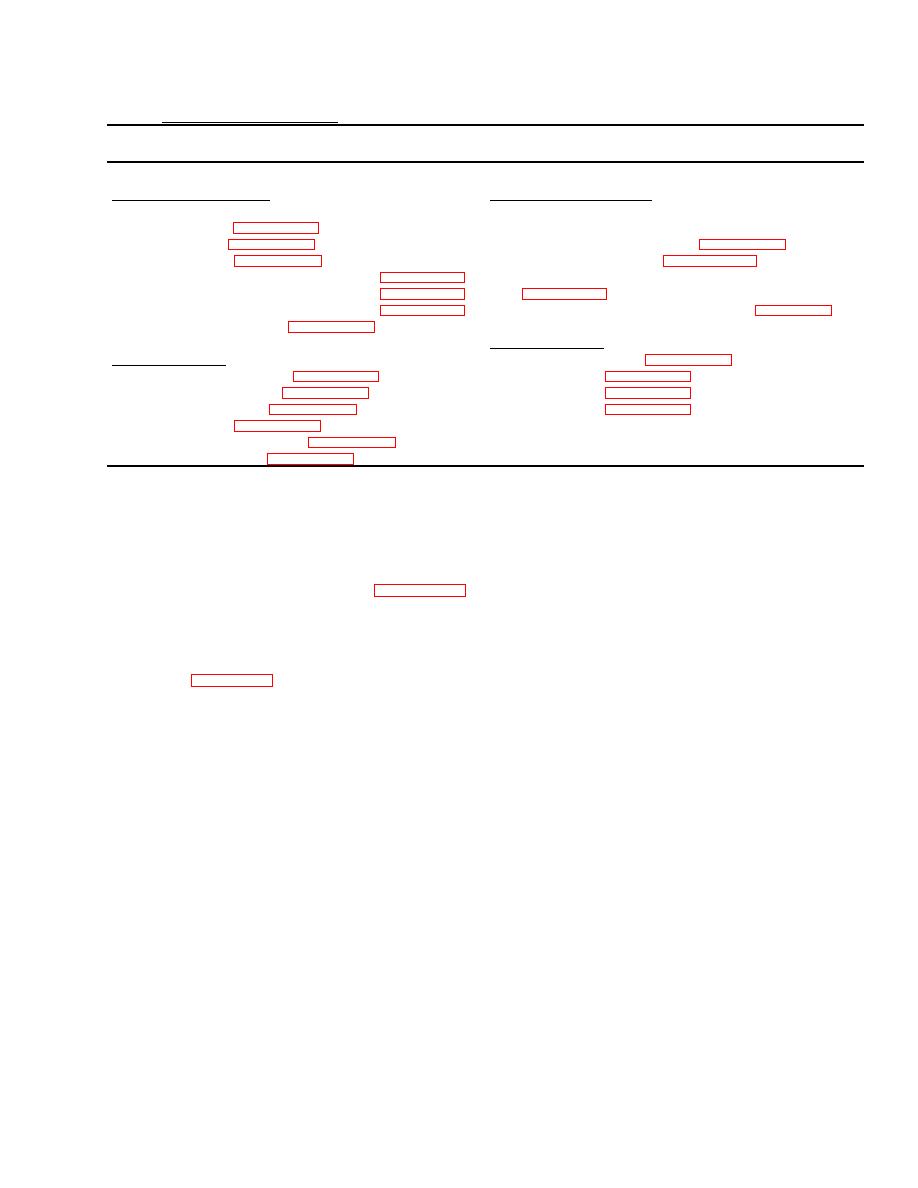

a. Removal/Disassembly (Refer to Figure 3-10)

(1)

Unscrew strainer (1) from close nipple (2) and remove from ECU (3).

(2)

Disconnect tube assembly (4), tube assembly (5), and tube assembly (6) from three unions on

ECU (3) partition wall. Plug unions to prevent contamination of the hydraulic system. Refer to

(3)

Disconnect tube assembly (4) from elbow (7) on hydraulic motor (8). Remove and discard O-ring

(9) from elbow (7).

(4)

Disconnect tube assembly (5) from elbow (10) on hydraulic motor (8). Remove and discard O-ring

(11) from elbow (10).

(5)

Disconnect tube assembly (6) from connector (12) on adapter (13). Remove and discard O-ring

(14) from connector (12).

(6)

Remove three tube assemblies (4, 5, and 6) from ECU (3).

NOTE

Remove two elbows, connector, and adapter from hydraulic motor prior to removing

hydraulic motor and ring compressor from ECU. Otherwise, a vise will be required to hold

hydraulic motor.

Plug open ports on hydraulic motor to keep the hydraulic motor free of contaminants.

(7)

Remove elbow (7) from hydraulic motor (8). Remove and discard O-ring (15) from elbow (7). Plug

open port on hydraulic motor (8).

(8)

Remove elbow (10) from hydraulic motor (8). Remove and discard O-ring (16) from elbow (10).

Plug open port of hydraulic motor (8).