TM 10-5410-228-24

3.9.4

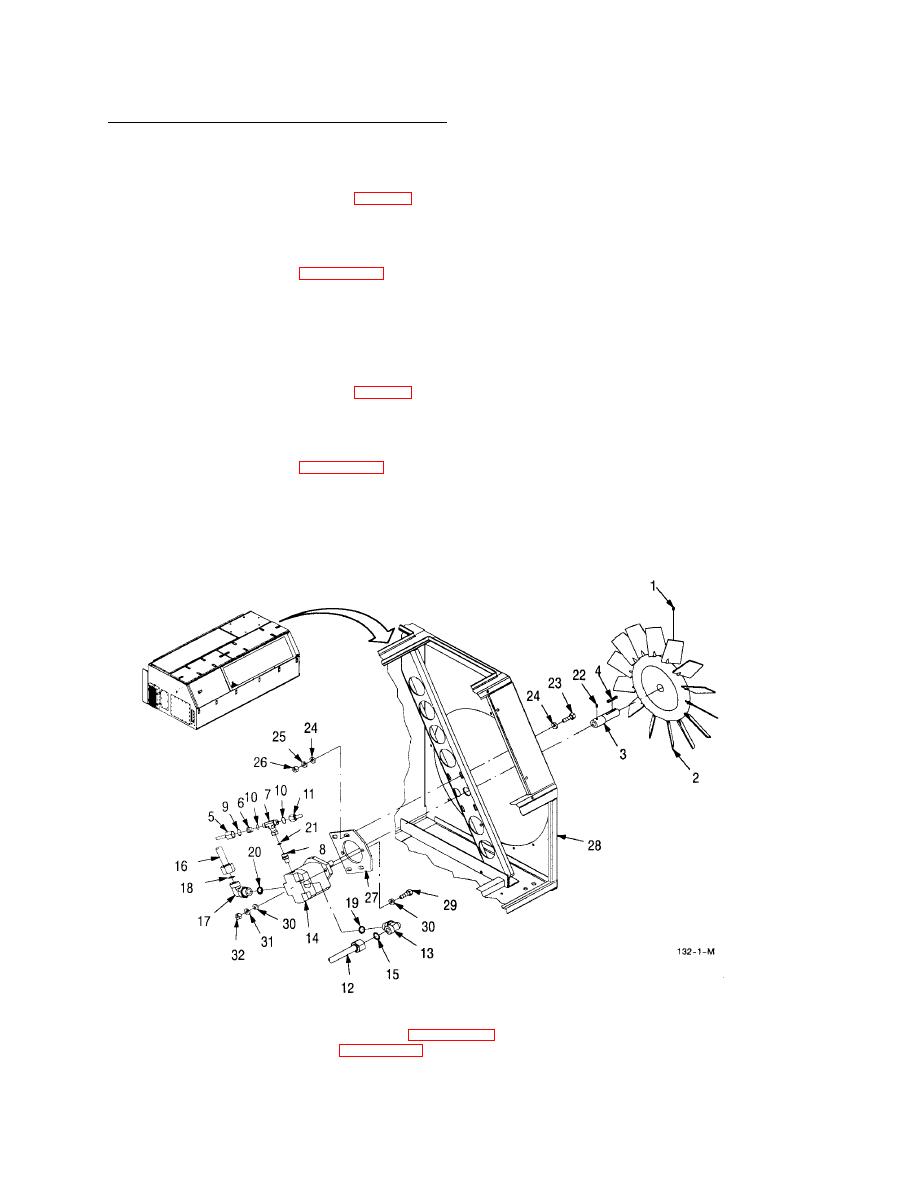

Condenser Fan/Motor Replacement Continued.

(28) Torque tee (7) and reducer (6) to 320 25 in.-lb (27 2 ft-lb).

(29) Torque two tube assemblies (5 and 11) to 320 25 in.-lb (27 2 ft-lb).

(30) Lubricate O-ring (15) (Item 58, Appx E) with a light coating of hydraulic fluid and install new

O-ring (15) on elbow (13). Ensure O-ring (15) is seated and retained properly.

(31) Remove plug from tube assembly (12). Check tube assembly (12) sealing surfaces for damage or

material build up. Clean any material build up with clean, lint-free cloth. If required, replace

tube assembly (12) per para 3.9.11.

(32) Coat male threads of elbow (13) with hydraulic fluid and install tube assembly (12) on elbow

(13), finger tight. Adjust position of tube assembly (12) and elbow (13) as required.

(33) Torque elbow (13) on hydraulic motor (14) to 1,680 75 in.-lb (140 6 ft-lb).

(34) Torque tube assembly (12) on elbow (13) to 1,080 45 in.-lb (90 4 ft-lb).

(35) Lubricate O-ring (18) (Item 58, Appx E) with a light coating of hydraulic fluid and install on

elbow (17). Ensure O-ring (18) is seated and retained properly.

(36) Remove plug from tube assembly (16). Check tube assembly (16) sealing surfaces for damage or

material build up. Clean any material build up with clean, lint-free cloth. If required, replace

tube assembly (16) per para 3.9.11.

(37) Install tube assembly (16) on elbow (17), finger tight. Adjust position of tube assembly (16) and

elbow (17) as required.

(38) Torque elbow (17) on hydraulic motor (14) to 1,680 75 in.-lb (140 6 ft-lb).

(39) Torque tube assembly (16) on elbow (17) to 1,080 45 in.-lb (90 4 ft-lb).

Follow-on maintenance: Fill hydraulic reservoir per para 2.14.3, apply system power and check for leaks,

close or install ECU doors and covers per para 2.14.1, remove ECU work platform (reference TM 10-5410-

228-10).

3-54