TM 10-5410-228-24

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Tools/Test Equipment:

Equipment Conditions:

Shop Equipment, Automotive Maintenance and

Power shut off, power panel and rear control panel

Repair (Item 38, Appendix B)

tagged.

Gloves (Item 16, Appendix B)

ECU covers and doors opened or removed

Goggles (Item 17, Appendix B)

(see para 2.14.1).

11/16 Inch Crowfoot Wrench (Item 53, Appendix B)

Hydraulic system drained (see para 2.14.3).

13/16 Inch Crowfoot Wrench (Item 54, Appendix B)

ECU work platform installed (reference

15/16 Inch Crowfoot Wrench (Item 55, Appendix B)

TM 10-5410-228-10).

1-1/8 Inch Crowfoot Wrench (Item 57, Appendix B)

1-3/8 Inch Crowfoot Wrench (Item 60, Appendix B)

References:

TM 10-5410-228-10

1-7/8 Inch Crowfoot Wrench (Item 63, Appendix B)

Torque Wrench (Item 66, Appendix B)

Materials/Parts: (Cont.)

Twenty Lockwashers (Item 17, Appendix E)

Materials/Parts:

Drain Pan (Item 28, Appendix B)

Three Lockwashers (Item 18, Appendix E)

Hydraulic Fluid (Item 24, Appendix C)

Twenty-five Tie-down Straps (Item 86, Appendix E)

Wiping Rags (Item 39, Appendix C)

O-ring (Item 67, Appendix E)

Sealant (Item 47, Appendix C)

Locknut (Item 8, Appendix E)

NOTE

Hydraulic tubes are secured using straight thread connectors. Main hydraulic hoses are

identified by their large size and the fact that they have shut off valves in their lines.

Many tubes and hose connections used on the CBPS system contain an O-ring to prevent

unwanted escape and loss of hydraulic fluid. O-rings, identified in Appendix E, are

mandatory replacement parts.

Tubes or hoses may have to be loosened or removed completely when performing

maintenance in the ECU.

A small amount of hydraulic fluid will be released when removing a tube or hose. Drain

excess fluid from hose or tube into cup or container. Clean any spillage with rags.

Remove/disassemble only to the extent necessary to remove or replace defective

assemblies/components. Use standard maintenance shop practices/procedures.

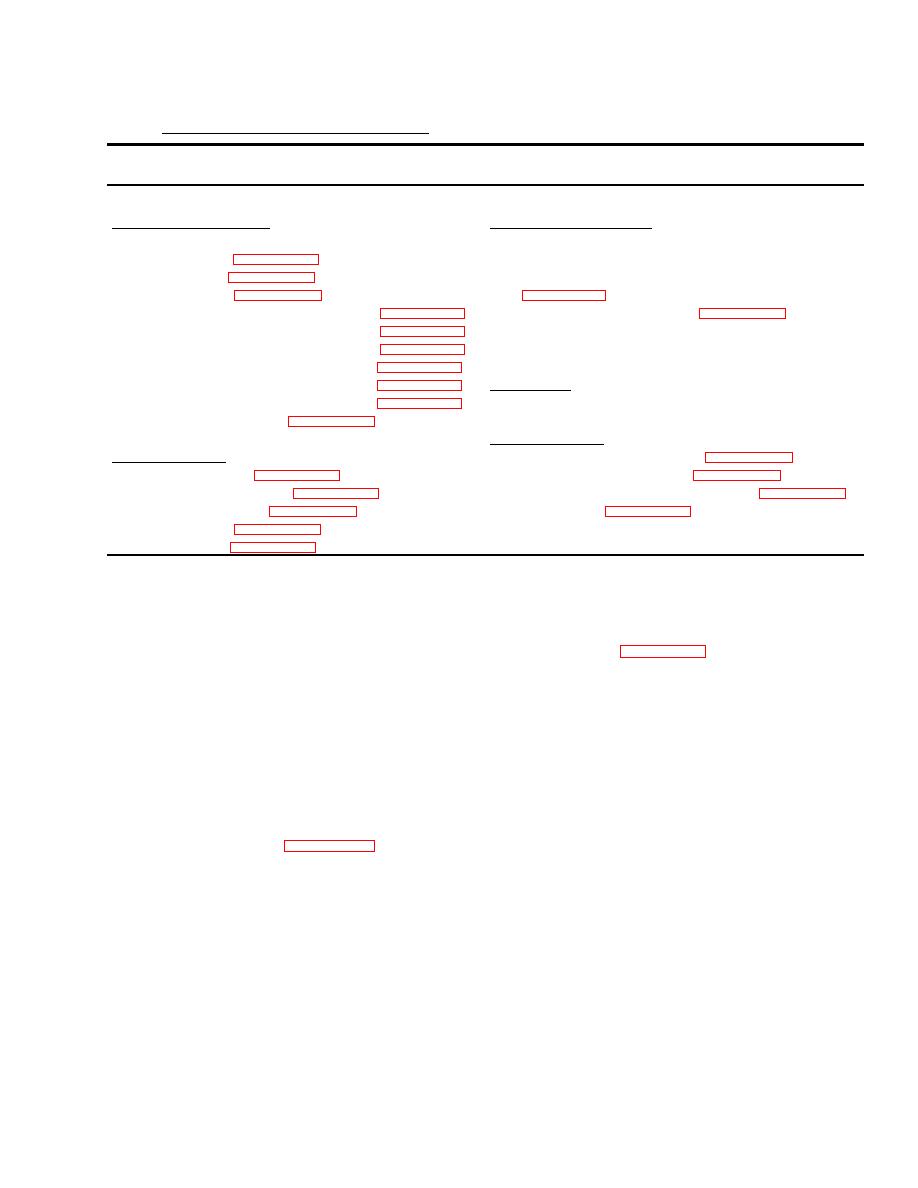

Hydraulic Tubes.

a. Removal (Refer to Figure 3-16)

(1)

Remove nut (1), lockwasher (2), flat washer (3) and screw (4) securing loop clamp (5). Remove

loop clamp (5) from hydraulic tube. Discard lockwasher (2).

(2)

Disconnect tube from fitting or elbow. Remove and discard O-ring.

NOTE

Remove fittings from hydraulic pump/motor before removing hydraulic pump/motor.

Otherwise a vise will be required to hold hydraulic pump/motor in order to loosen fittings.

(3)

Remove fitting, plug or elbow from component. Remove and discard O-ring.

(4)

Plug port of component and open end of tube or hose to keep hydraulic system free of