T.O. 33B-1-1

4-29

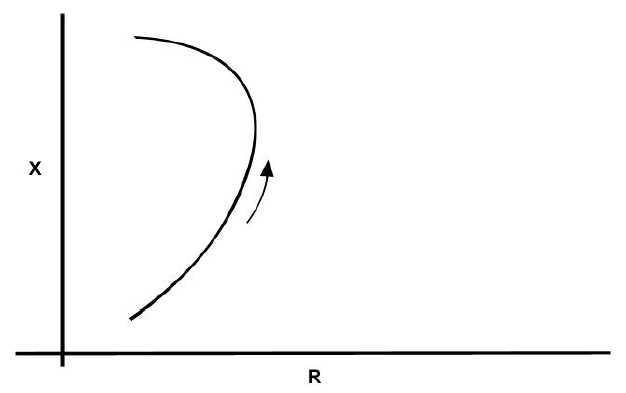

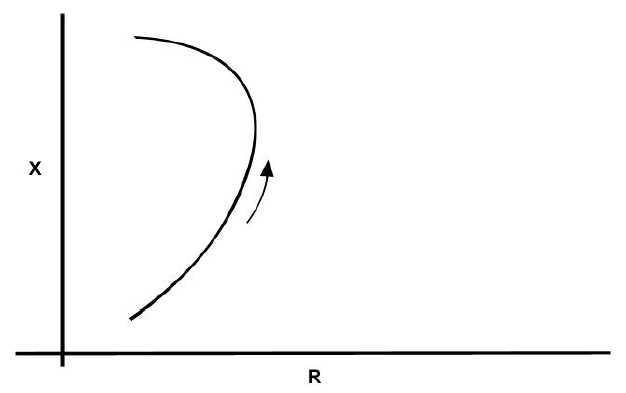

corresponds to a clockwise direction along the loop. The point at which the loop rejoins the curve represents the

effective depth of penetration in the coating.

4.3.3.5.6

Cracks, Lift Off and Conductivity.

The impedance changes due to surface cracks of different depths. The change for cracks will lie between the lift-off

and conductivity (s). As the crack depth increases the response moves further from lift-off and closer to decreasing

conductivity (s).

4.3.4

Heat Treat Condition or Hardness.

Heat treating (or age hardening) a metal changes its hardness and its electrical conductivity. Just as above, the

aluminum alloys have been the most investigated for the hardness/conductivity effect. Again, the impedance change is

along the conductivity curve in the range of 25% IACS to 65% IACS.

4.3.4.1

Temperature

Changing the temperature of a part changes its electrical conductivity. All metals become less conductive as

temperature rises. This would be seen on the impedance plane as a movement along the conductivity curve toward the

zero (air) end of the curve. For aluminum alloys, conductivity decreases about 1% IACS for a 20O F increases in

temperature (see Figure 4-24).

Figure 4-24. Effect of Temperature Increase

If a conductivity meter is being used to check for proper alloy or heat treat condition, the temperature of all parts and

calibration standards must be the same and kept constant. A change in temperature could be interpreted as a change in

alloy or hardness, since all three factors may change the conductivity of a metal.

4.3.4.2

Crack Detection, Nonferromagnetic Materials

As discussed previously, the amplitude of the response from a surface crack increases as the crack gets deeper. When

the crack reaches three standard depths it is interrupting essentially all of the eddy current flow and no increase in