T.O. 33B-1-1

4-27

an eddy current inspection for cracks in aluminum alloy 7075-T6, with a conductivity of about 30% IACS uses a

frequency of 200 kHz. To perform a comparable inspection on a titanium alloy, TI 6-4 with a conductivity of about 1%

IACS, a frequency of about 6 MHz would be required.

4.3.3.5.2

Lift Off.

As a test coil is moved away from a part (increasing lift-off) the coupling between test coil and inspection part is

decreased. The magnitude of the impedance change for a specific change in an inspection variable is also decreased.

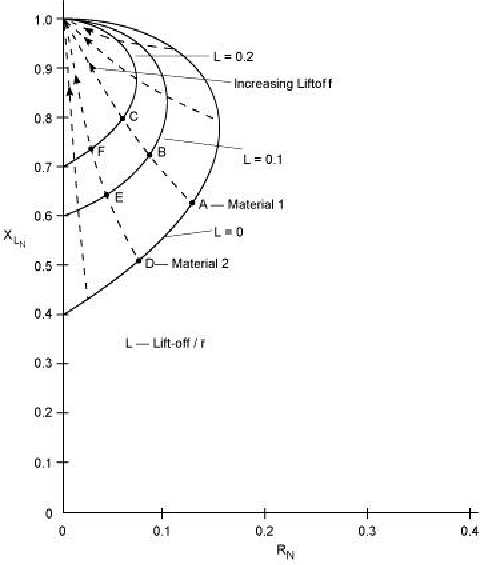

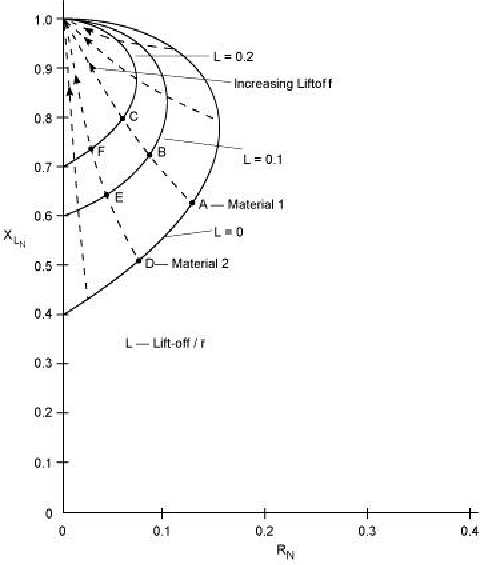

For probe coils, the dotted lines connecting points representing the same material properties but with various amounts

of lift-off have some curvature as evidenced in Figure 4-22. The line ABC represents the increase lift-off for material

1. Line DEF represents the increase in lift-off for material 2. The line from point A to point D represents the increase

in conductivity of material 2 compared to material 1 at one lift-off value. With more lift-off, lines BE and CF are

increasingly shorter, indicating a smaller indicated change in the conductivity.

Figure 4-22. Impedance Diagram Showing the Effect of Lift-Off.

4.3.3.5.3

Relative Magnetic Permeability.

Although increases in conductivity of an inspection part or the test frequency result in a decrease in the normalized

impedance of a test coil, an increase in magnetic permeability results in an increase in impedance.