T.O. 33B-1-1

3-100

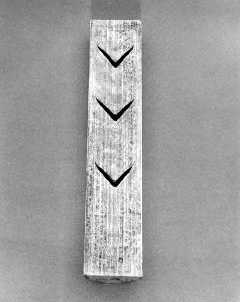

Figure 3-55. Section through Severe Cupping in a 1 3/8-Inch Bar.

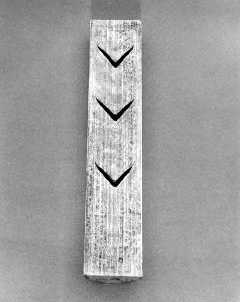

d. Cooling Cracks. When alloy and tool steel bars are rolled and subsequently run out onto a bed or table

for cooling, stresses may be set up due to uneven cooling which can be severe enough to crack the bars.

Such cracks are generally longitudinal, but not necessarily straight. They may be quite long, and

usually vary in depth along their length. Figure 3-56 shows the magnetic particle indications of such a

crack, and also sections through the crack at three points to illustrate the variation in crack depth. The

magnetic particle indication varies in intensity, being heavier at points where the crack is deepest.

(a) Surface Indications.

(b) Cross-Section Showing Depth.

Figure 3-56. Magnetic Particle Indications of Cooling Cracks in an Alloy Steel Bar.