T.O. 33B-1-1

3-102

Figure 3-59. Surface of a Steel Billet Showing a Lap.

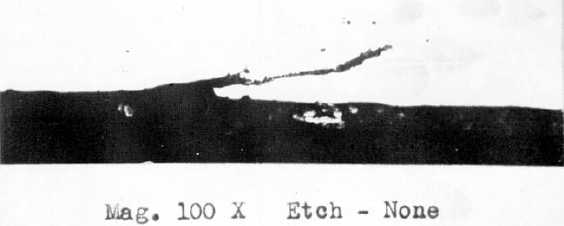

Figure 3-60. Cross-Section of a Forging Lap (Magnified 100X).

h. Burning. Overheating of forgings, to the point of incipient melting, results in a condition which

renders the forging unusable in most cases, and is referred to as burning. However, the real source of

the damage is not oxidation, but the material becoming partially liquefied due to the heat at the grain

boundaries. Burning is a serious defect but is not generally shown by magnetic particle testing.

i. Flash Line Tears. Cracks or tears along the flash line (see Glossary) of forgings are usually caused by

improper trimming of the flash. If shallow they may "clean up" during machining. Otherwise they are

considered defects. Such cracks or tears can easily be found by magnetic particles. (See Figure 3-61.)