T.O. 33B-1-1

3-103

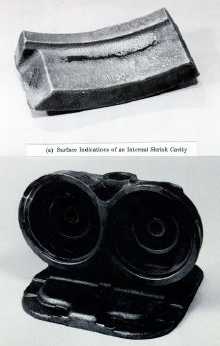

Figure 3-61. Magnetic Particle Indication of Flash Line Tear in a

Partially Machined Automotive Spindle Forging.

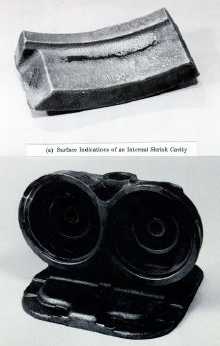

j. Casting Defects. Steel and iron castings are subject to a number of defects which magnetic particle

testing can easily detect. Surface discontinuities are formed in castings due to stresses resulting from

cooling, and are often associated with changes in the cross section of the part. These may be hot tears

or they may be shrinkage cracks that occur as the metal cools down. Sand from the mold can be

trapped by the hot metal and form sand inclusions on or near the surface of castings. Gray iron castings

may be quite brittle, and can be cracked by rough handling. (See Figure 3-62.)

Figure 3-62. Magnetic Particle Indications of Defects in Castings.