T.O. 33B-1-1

3-97

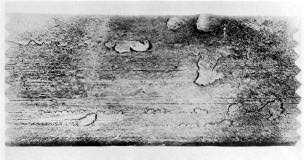

Figure 3-50. Magnetic Particle Indication of a Sub-Surface Stringer of Non-Metallic Inclusions

e. Internal Fissures. Because of the stresses set up in the ingot as the result of shrinkage during cooling,

internal ruptures may occur which may be quite large. Since air does not reach the surfaces of these

internal bursts, they may be fused during rolling or other forming operations and leave no discontinuity.

If there is an opening from the fissure to the surface, however, air will enter and oxidize the surfaces.

In this case fusion does not occur, and they will remain in the finished product as discontinuities.

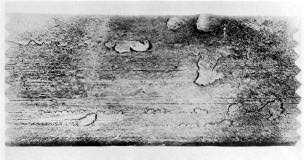

f. Scabs. When liquid steel is first poured into the ingot mold there is considerable splashing or spattering

up and against the cool walls of the mold. These splashes solidify at once and become oxidized. As the

molten steel rises and the mold becomes filled, these splashes will be reabsorbed to a large extent into

the metal. But in some cases they will remain as scabs of oxidized metal adhering to the surface of the

ingot. These may remain and appear on the surface of the rolled product. If they do not go deeply into

the surface they may not constitute a defect, since they may be removed by machining. Figure 3-51

illustrates this condition on a rolled bloom.

Figure 3-51. Scabs on the Surface of a Rolled Bloom

g. Ingot Cracks. Surface cracking of ingots occurs due to surface stresses generated during cooling of the

ingot. They may be either longitudinal or transverse, or both. As the ingot is formed into billets by

rolling, these cracks form long seams. Inspection of billets for seams of this type with magnetic

particles is now common practice in modern mills. Detection at this point permits removal of the seams

by flame scarfing, chipping or grinding without waste of good metal. If not removed before further