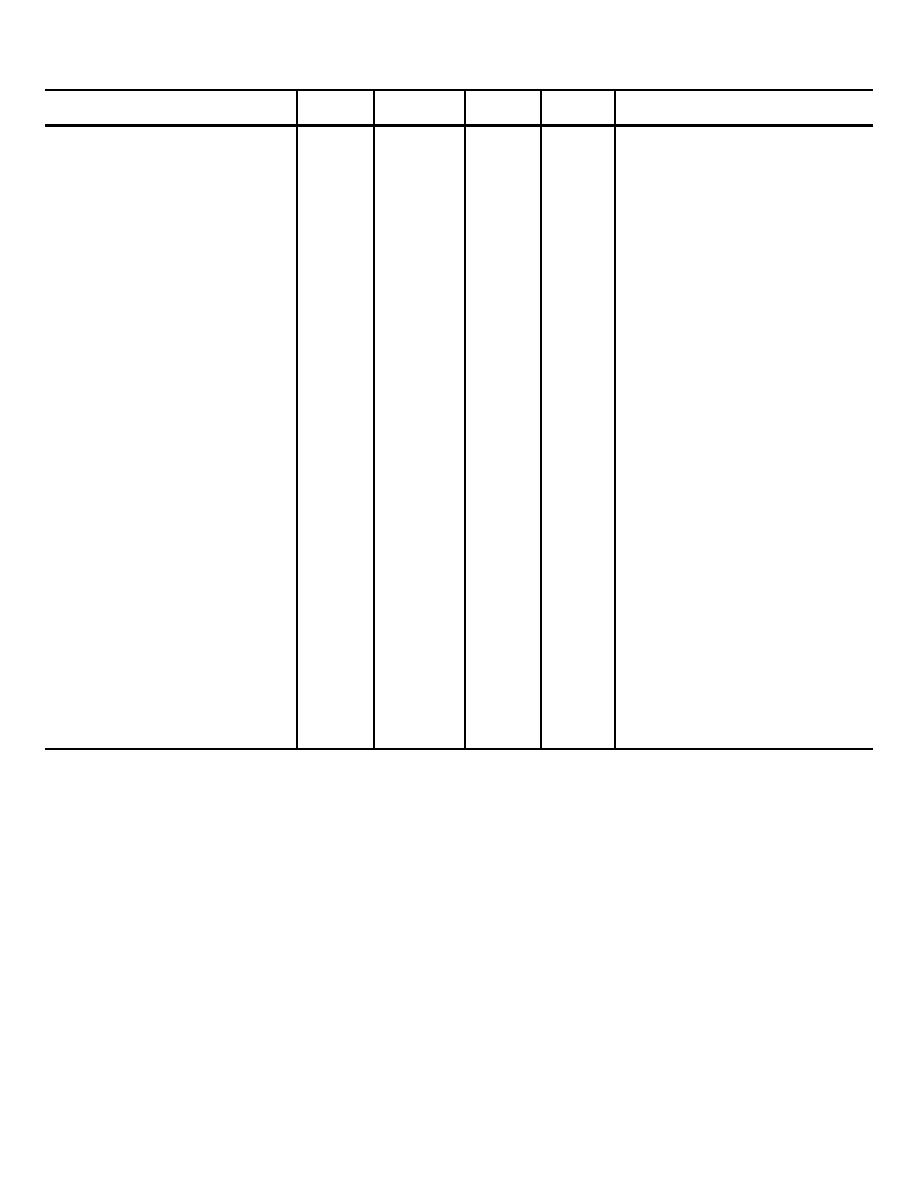

Table XVII. Qualification and Analysis Evaluation Schedule

Test

Temp

Cartridges

Units

Firings

Remarks

( )

F

required

required required

Structural ......................................

-65 ................

2 ..........

70 ................

2 ..........

200 ................

2 ..........

Endurance.....................................

70 ................

2 ..........

Demagnetization ........................... .............

†All

†All ..........

Hydrostatic ....................................

70 ................

†All ..........

Torque ..........................................

70 ................

†All ..........

Environmental............................... .............

..........

Vibration ................................

†All

6

6 ..........

The same 6 units through all

Salt spray ............................... ............. ................ ...........

..........

environmental tests

Sand and dust......................... ............. ................ ...........

..........

High temperature .................... ............. ................ ...........

..........

Low temperature ..................... ............. ................ ...........

..........

Temperature shock ................. ............. ................ ...........

..........

Temperature-altitude humidity

.............

15+6

6

6 Fire all cartridges as well as the 6

cycle.

units.

Firing mechanism..........................

Mechanical .............................

70

................

†All

..........

Gas ........................................

65- 6

................

..........

70

................

6

..........

200

................

6

..........

Electrical ................................

65

................

20

..........

Tested for no-fire and all-fire con

70

................

20

..........

-ditions.

200

................

20

..........

Ignition system .............................

-90

10

10

10

Drop ..............................................

70

3

3

..........

Inert

cartridges

Locked shut ..................................

-65

2

2

2

Use units from drop test.

200

8

8

8

No-load ........................................

65

2

2

2

200

8

8

8

Performance ................................

-65

20

20

20

At least 5 new units for each tem

70

20

20

20

perature group.

200

20

20

20

† "All" means every unit fabricated for qualification and analysis tests.

are disassembled and inspected for signs

chamber to establish a relative humidity

of moisture or deterioration of the

(RH) of 95 to 100 percent. This humidity

propellant or primer charges.

The

is maintained for the remainder of the

remaining cartridges are fired (five at -65

test.

and five at 200 F.) to check their

(2) As soon as possible after completion of

functioning only, so it is unnecessary to

the environmental tests, two units are

record performance data.

Should

disassembled and inspected for signs of

cartridge modification be necessary as a

moisture or deterioration. If moisture is

result of these tests, a new series of tests

detected or if deterioration has progressed

must be initiated.

to the point where the unit may

h. Firing Mechanism Evaluation.

malfunction, the design must be modified

and a new series of tests initiated. If the

(1) Mechanical firing mechanisms generally

two units pass the test, they are

are required to function when the sear

reassembled and all six units are fired at -

(initiator pin) is pulled with a specific

65F.

force. The sear actuation force may be

determined by placing the device in a vise

(3) Five of the cartridges subjected to

and pulling the sear with a spring scale.

temperature, altitude, and humidity tests

113