TM 5-3740-214-14

NOZZLE ASSEMBLY MAINTENANCE (Continued)

(1)

If fluid nozzle is plugged, or partially obstructed, soak the fluid nozzle in acetone to dissolve the gunk

and varnish.

(2)

Carefully clean the air cap holes with a toothpick.

(3)

Wipe the air cap with a clean rag.

(4)

Unplug the fluid nozzle holes with a toothpick.

(5)

Wipe the fluid nozzle with a clean rag.

(6)

Clean air grooves on back of fluid nozzle.

c. Reassemble and install nozzle assembly.

(1)

Attach adjusting nut, nipple, O-ring and swivel elbow to street elbow.

(2)

Attach O-ring, adjusting nut, nipple, and nozzle body to swivel elbow.

(3)

Attach nipple, solenoid valve, and support bracket to nozzle body.

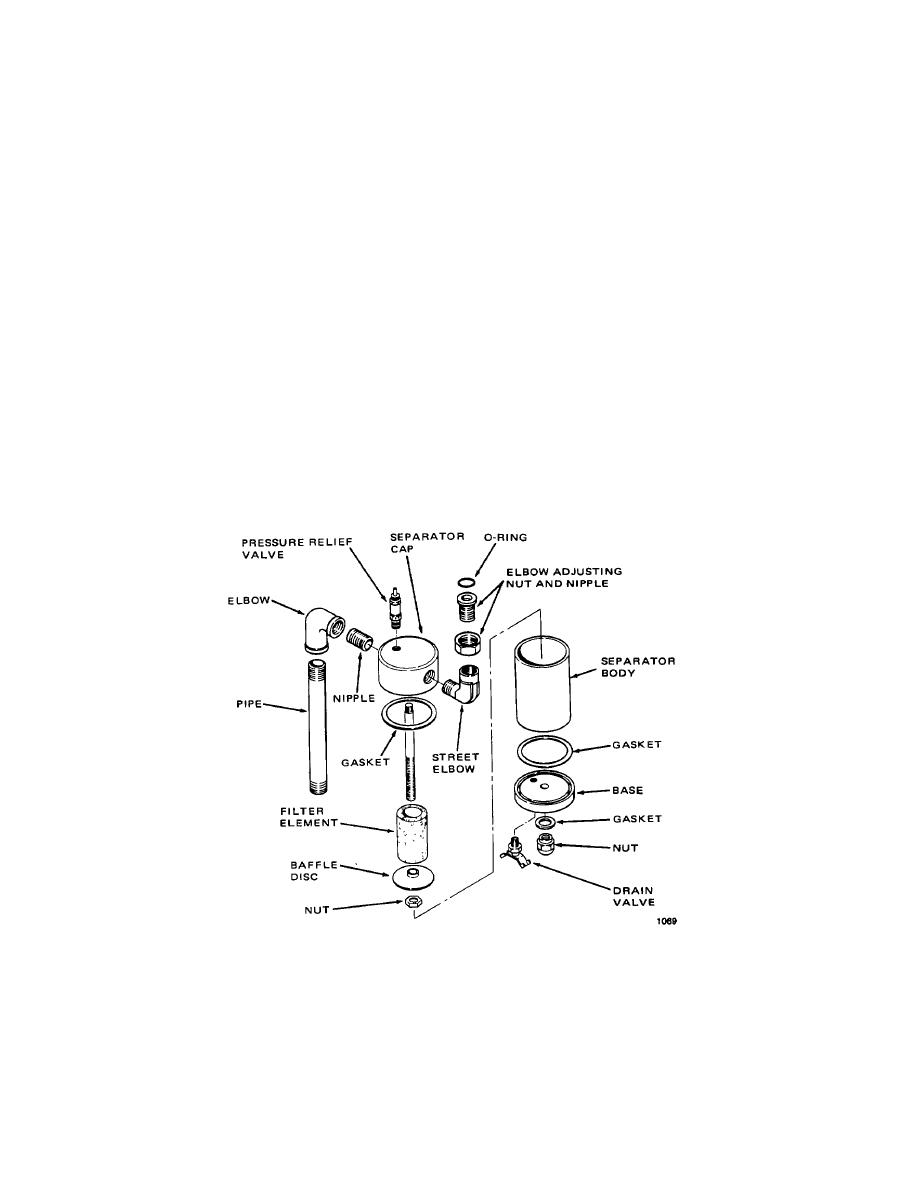

SEPARATOR MAINTENANCE

Figure 4-96. Separator Disassembly

4-87