TM 5-3740-214-14

Table 2-1. Operator Preventative Maintenance Checks and Services (Continued)

B - Before

D - During

A - After

INTERVAL

FOR READINESS REPORT-

ITEM

ITEM TO BE INSPECTED.

ING, EQUIPMENT IS NOT

NO.

B

D

A

PROCEDURE

READY/AVAILABLE IF:

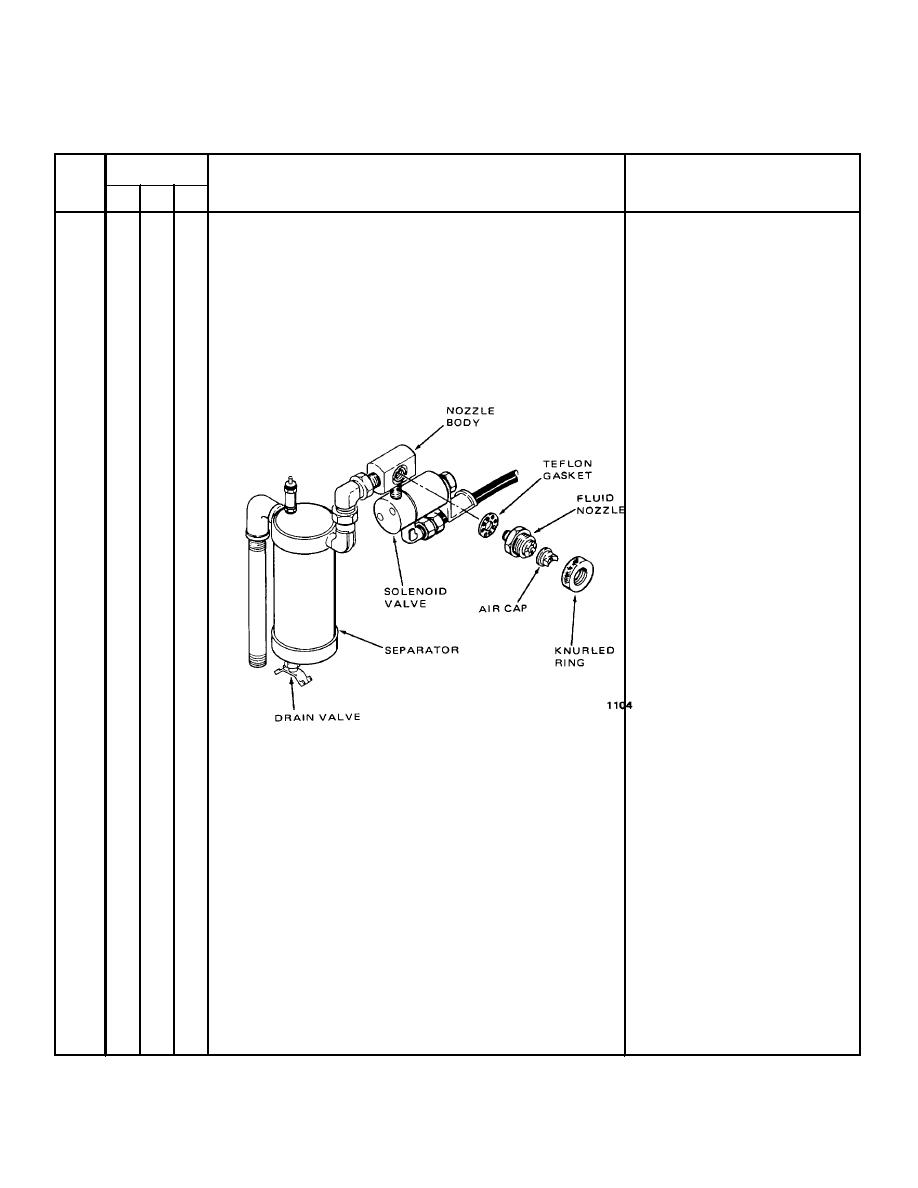

NOZZLE ASSEMBLY (Continued)

(2) Soak the fluid nozzle in acetone (0-A-51 F)to dissolve

the gunk and varnish.

(3) Carefully clean out the fluid nozzle holes with a toothpick

or other soft non-metallic object.

(4) Wipe the fluid nozzle surfaces with a clean rag.

(5) If teflon gasket is stretched out of shape, replace it.

Figure 2-14. Nozzle Assembly

c. Reassemble nozzle assembly.

CAUTION

Do not over tighten the fluid nozzle. This would

damage the teflon gasket and cause air leaks.

(1) Thread fluid nozzle and teflon gasket into nozzle body.

(2) Install air cap and knurled ring. Tighten knurled ring by

hand.

d. Check nozzle assembly for air leaks.

2-11