TM 5-3710-214-14

Table 2-1. Operator Preventive Maintenance Checks and Services (Continued)

B - Before

D - During

A - After

INTERVAL

FOR READINESS REPORT-

ITEM

ITEM TO BE INSPECTED.

ING, EQUIPMENT IS NOT

NO.

B

D

A

PROCEDURE

READY/AVAILABLE IF:

NOZZLE ASSEMBLY (Continued)

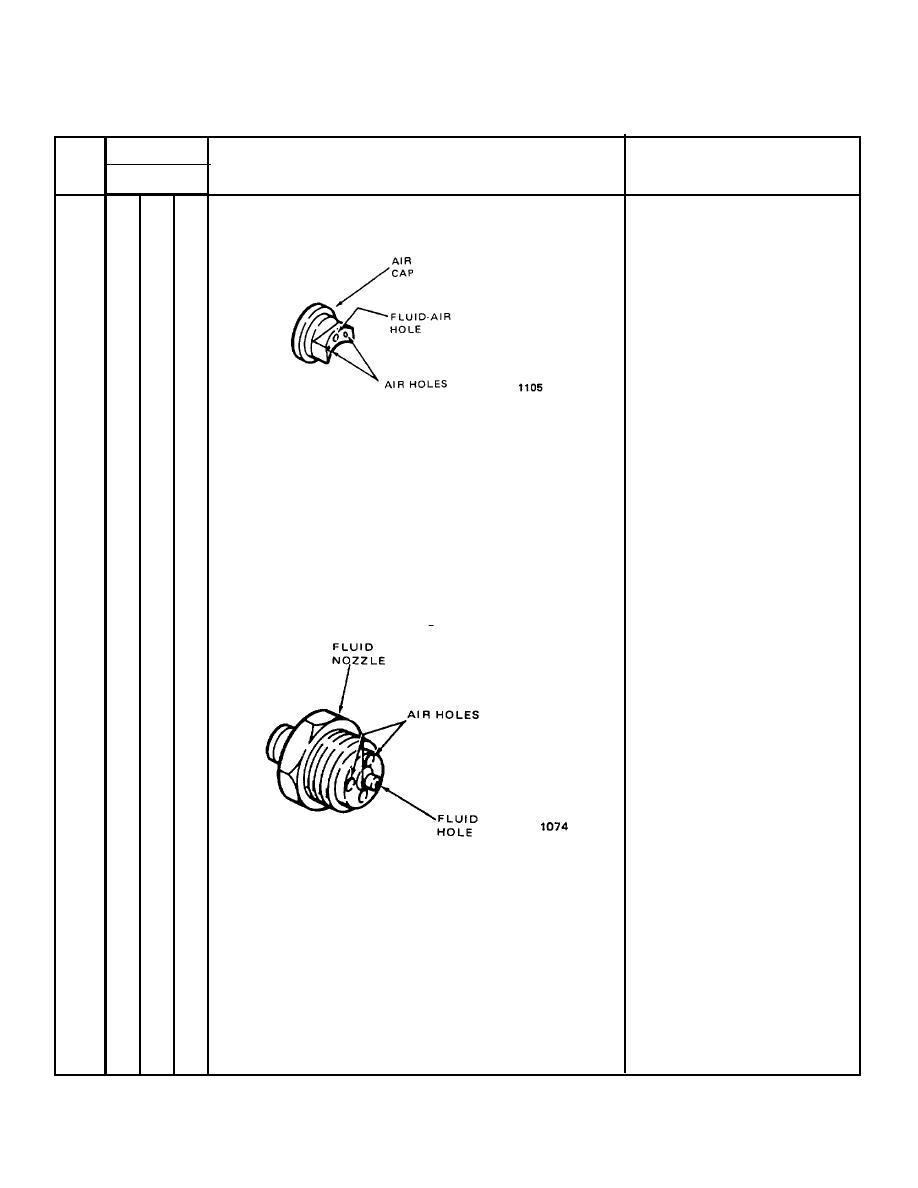

Figure 2-12. Air Cap

a. Make sure air cap holes are not coated with oil

The nozzle assembly is blocked

residue, partially blocked, or plugged.

or leaks

(1) Remove knurled ring and air cap.

(2) Soak the air cap in acetone (0-A-51F) to dissolve

the gunk and varnish.

(3) Carefully clean out the air cap holes with a tooth-

pick or other soft non-metallic object.

(4) Wipe the air cap, the exposed fluid nozzle sur-

faces, and the fluid hole projection with a clean rag.

Figure 2-13. Fluid Nozzle

b. Make sure fluid nozzle is not blocked or plugged.

The fluid nozzle leaks air

(1) Remove fluid nozzle and teflon gasket.

NOTE

Be sure to check the air groove in the back

of the fluid nozzle and clean it as necessary.

2-10