TM 3-4230-209-30&P

2-32

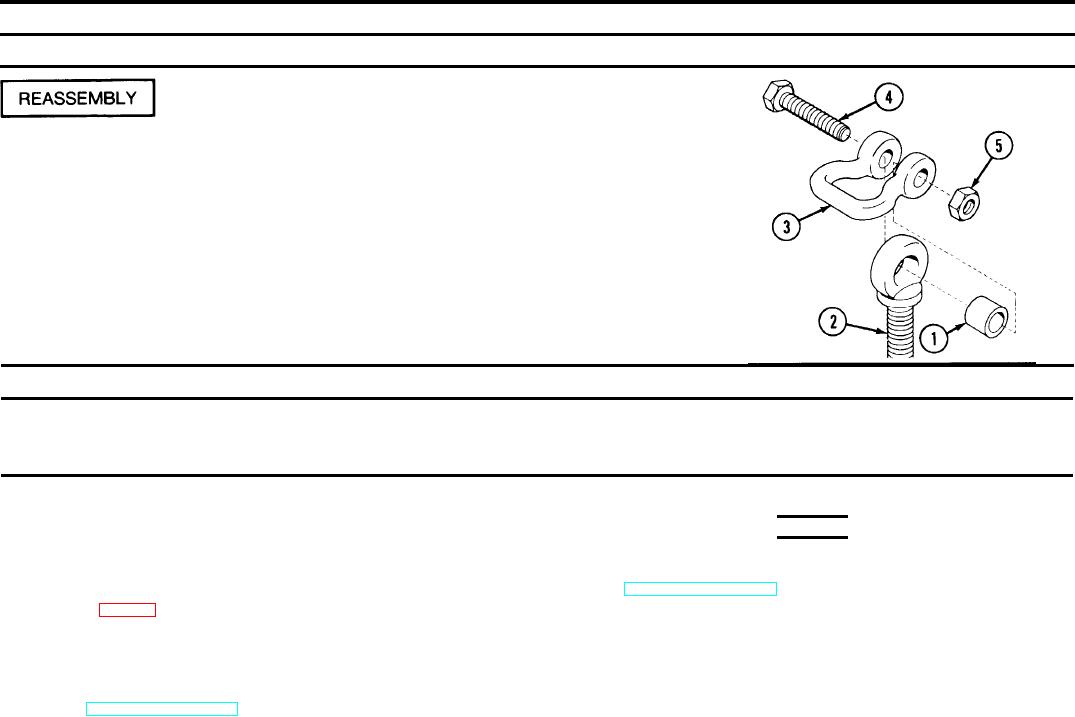

2-13. CLEVIS AND EYE BOLT ASSEMBLY (CONT).

REMARKS

ACTION

LOCATION/lTEM

Clevis and Eye Bolt Assembly/

Insert spacer (1) into large hole in eye bolt (2). Saddle shackle (3) over eye

Spacer (1)

bolt (2), and aline hole in shackle (3) with hole in spacer (1).

Eye bolt (2)

Shackle (3)

Insert new bolt (4) through holes and screw on new nut (5). Tighten nut (5)

Bolt (4)

on bolt (4) snug but not tight. Tack-weld nut (5) to bolt (4) after reassem-

Nut (5)

bly is complete.

Paint clevis and eye bolt assembly with polyurethane coating after

welding.

2-14. PUMP UNIT ASSEMBLY.

This task covers:

c. Reassembly

a. Disassembly

b. Repair

Special Safety Instructions

INITIAL SETUP

Tools and Special Tools

WARNING

Automotive Maintenance and Repair Field Maintenance

Negative battery cable must be disconnected from the battery any time that

Shop Equipment, Basic, Less Power (SC 491 0-95-CL-A31 )

the control panel assembly is being removed or is removed from the pump

unit. See TM 3-4230-209-20&P.

Materials/Parts

Ground wire (fig D-16)

Battery and battery compartment area may be coated with acid due to

Transmitter wire (fig D-17)

spillage and/or fumes. Wear protective clothing when working in this area.

Equipment Condition

Before eating, smoking, or touching your face or clothing, wash your hands

Engine and pump unit protective cover and pump unit panels are removed and

with a solution of baking soda and water, then flush them with clear water.

fuel is drained from fuel tank. Unit maintenance authorized components are

If battery acid gets into your eyes, flush them with clean water. Obtain

removed in TM 3-4230-209-20&P and are not covered in this manual.

medical treatment immediately. Failure to do so may cause blindness.