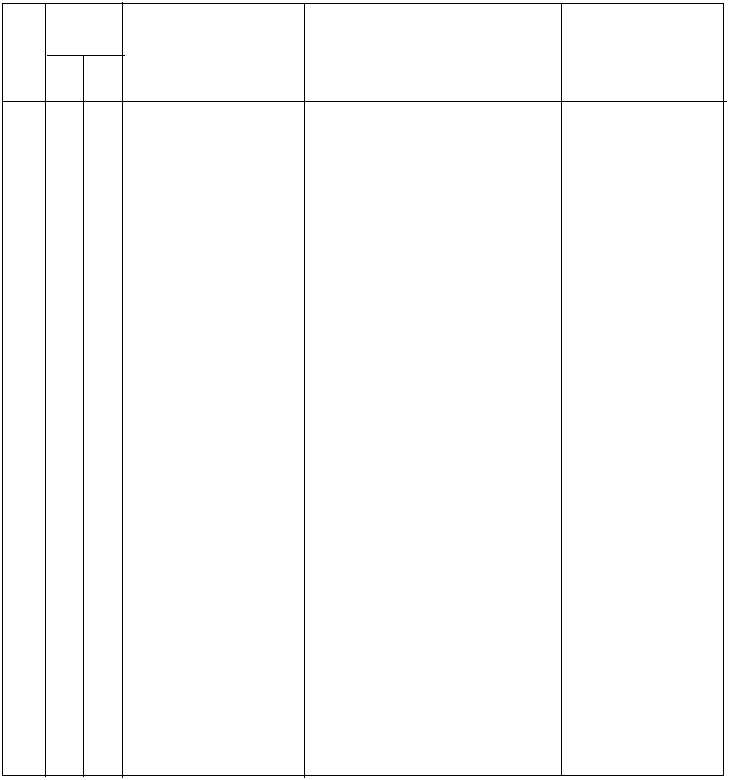

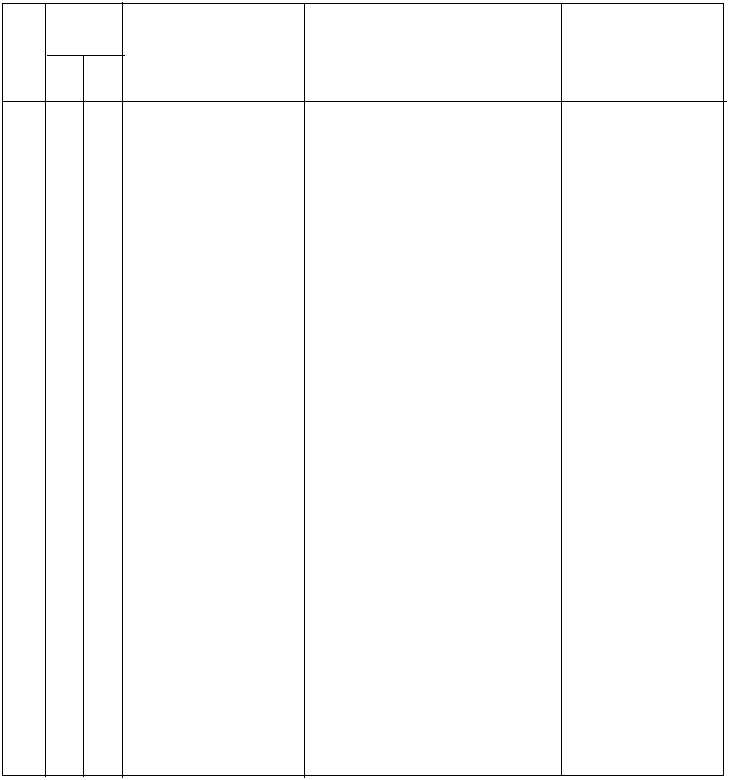

TM 10-8415-208-12

Table 2-1. Operator Preventive Maintenance Checks and Services for the STEPO-I (Cont)

B - Before Operation

D - During Operation

INTERVAL

Item

Item To Be

Procedures

Equipment Is

No.

Inspected

Check For And Have Repaired

Not Ready/

B

D

Or Adjusted As Necessary

Available If:

20

•

Face Piece

Inspect for cuts, holes or any

Cuts, holes or

other damage and ensure inlet

damage is found or

and outlet valves are installed.

inlet and outlet valves

are missing.

21

•

Ensure lens is clean.

Dirty lens.

22

•

Breathing

Inspect breathing tube for

Damage is found or

Tube

damage and ensure the cover

cover not tied on.

is tied at both ends.

23

•

Face Piece

Ensure warning light lamp is

Lamp not installed.

Light

installed.

CAUTION

Equipment corrosion hazard. Remove

the battery from the EBA battery box

when the unit is not in use. Failure to

remove the battery may cause

equipment damage from corrosion and

require replacement of the EBA.

24

•

Battery

Ensure "D" size battery is installed.

Battery is missing.

25

•

Cylinder

Check the pressure gauge to

Cylinder is charged

ensure the cylinder is charged

below the full mark.

to approximately 2500 psig.

26

•

Cushion

Ensure cushion cover is

Cushion cover not

Cover

installed.

installed.

NOTE

PMCS steps 27 through 43 are checked

only when using the rebreather system.

Rebreather

System

(Rebreather

System Mode)

27

•

Rebreather

Visually ensure unit is clean.

Unit is dirty.

28

•

Bypass Button

Depress the bypass button to

The bypass button

ensure it operates properly.

fails to operate.

29

•

Face Piece Lens

Ensure lens is clean.

Lens is dirty.

2-10