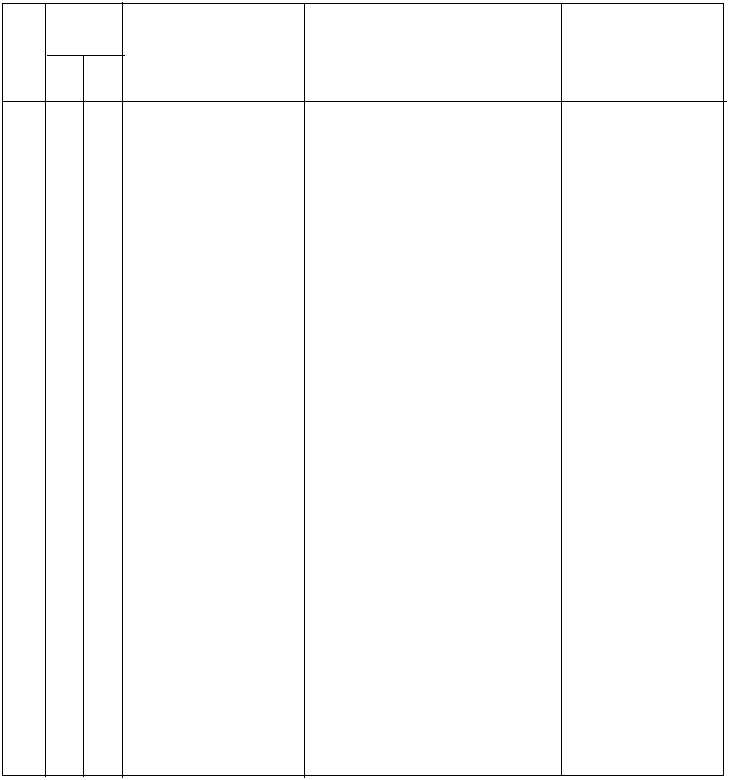

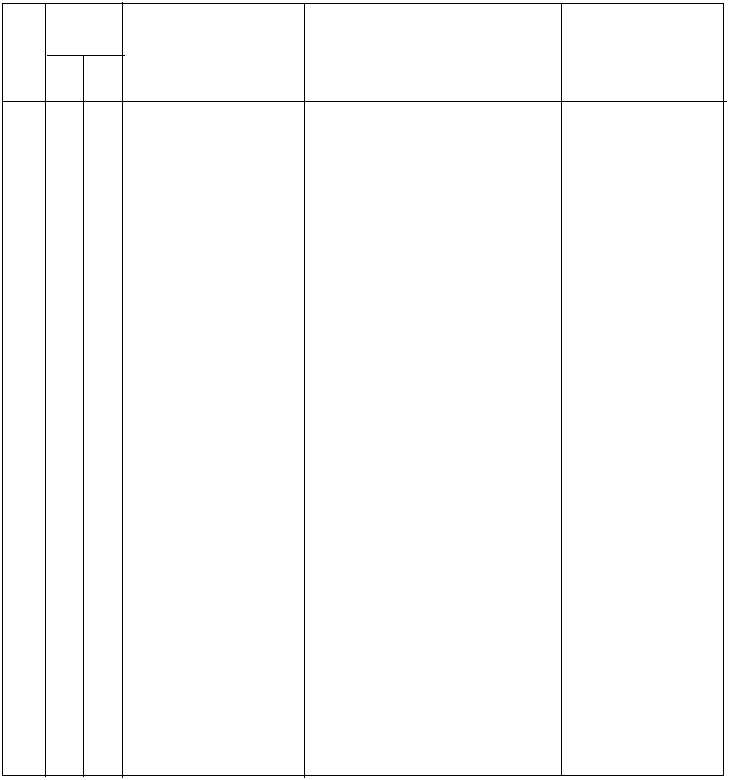

TM 10-8415-208-12

Table 2-1. Operator Preventive Maintenance Checks and Services for the STEPO-I (Cont)

B - Before Operation

D - During Operation

INTERVAL

Item

Item To Be

Procedures

Equipment Is

No.

Inspected

Check For And Have Repaired

Not Ready/

B

D

Or Adjusted As Necessary

Available If:

30

•

Face Piece

Inspect for cuts, holes or any

Cuts, holes or

other damage.

damage is found.

31

•

Air Hoses

Inspect hoses for cuts, holes or

Cuts, holes or

any other damage.

damage is found.

NOTE

The CO2 absorbent will be replaced

after each use or every 12 months.

32

•

CO2

Ensure maintenance tag

Maintenance tag is

Absorbent

indicates C02 absorbent is fresh.

missing or outdated.

33

•

Coolant

Ensure canister is frozen.

Canister is thawed.

Canister

34

•

Oxygen Bottle

Ensure bottle is pressurized

Bottle is below

and indicates 2,400 PSIG.

2,400 PSIG.

35

•

Adjustable

Inspect webbing for rips, tears,

Webbing is ripped or

Straps

missing or broken buckles and

torn or buckles are

cleanliness.

broken or missing.

Ice Vest

(Rebreather

System Mode)

36

•

Drain Valve

Ensure valve is closed.

Valve is left open.

37

•

Battery

Ensure a battery is installed.

Battery is missing.

38

•

Coolant Bag

Inspect bag for rips, tears or holes.

Bag is punctured.

NOTE

The coolant bag holds four (4) pounds of

cube or crushed ice or three (3) gel

packs. Gel packs require 8-10 hours to

fully freeze and provide longer operating

time. Approximately one (1) quart of

potable water is necessary to operate

the ice vest.

39

•

Ensure the required amount of

Ice, frozen gel

ice or gel packs and potable

packs or water are

water are installed.

not installed.

2-11