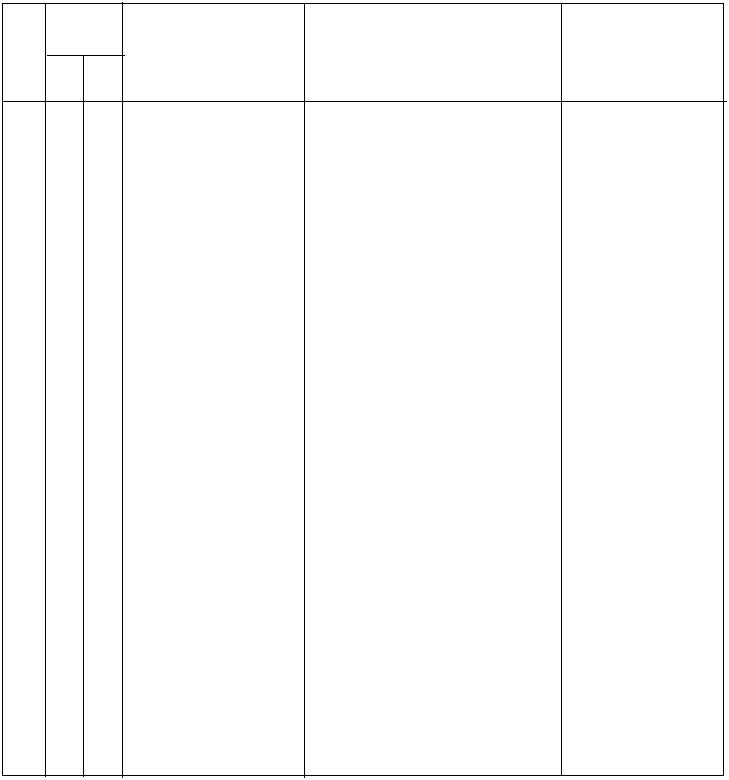

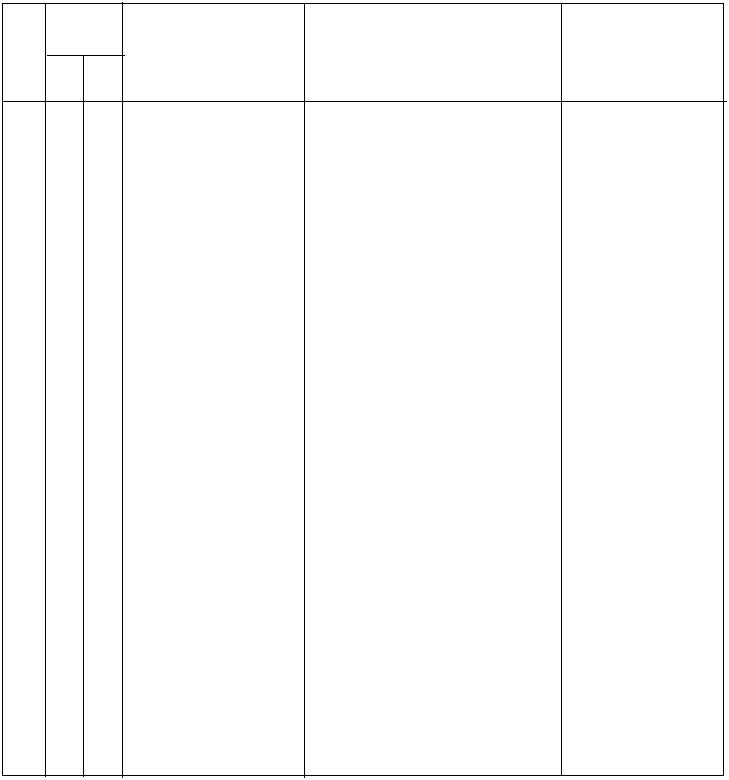

TM 10-8415-208-12

Table 2-1. Operator Preventive Maintenance Checks and Services for the STEPO-I

B - Before Operation

D - During Operation

INTERVAL

Item

Item To Be

Procedures

Equipment Is

No.

Inspected

Check For And Have Repaired

Not Ready/

B

D

Or Adjusted As Necessary

Available If:

Encapsulating

Protective

Suit

1

•

Fabric

Look for holes, cuts, pits, blisters, dela-

Damaged fabric is

mination, tunnels, lumps or imbedded

found.

foreign matter, uncoated areas and

scratches, abrasions, cracks, rips and

tears on the inside and outside of the

suit

2

•

Slide Fastener

Ensure slide fastener is in good working

Non-working slide

order.

fastener.

3

•

Storm Rap

Inspect hook and pile fastener tape to

Loose hook and pile

make sure it is not coming loose.

fastener tape.

NOTE

Damage may appear between the finger

area.

4

•

Glove Assembly

Inspect for a tight assembly, cuts,

A loose assembly or

cracks, rips and tears.

damage is found.

5

•

Seams

Ensure seam areas are not coming

Seams are loose.

loose. Inspect for open seam completely

Blisters, delamination,

through suit, strapping not cemented so

tunnels, loose strap-

it pulls off seam with little resistance,

ping, open seam or

blisters, delamination, tunnels and ex-

exposed stitching is

posed stitching.

found.

6

•

View Window

Inspect for a tight seal and cracks.

Loose seal or cracked

Clean window using a dean, damp cloth

window.

to remove dust and dirt.

7

•

Ensure FEP overlay is in place.

Overlay is missing.

8

•

Passthrough

Inspect suit opening and assembly pre-

Enlarged opening or

Assembly

formed packing for a proper and fight fit.

damaged preformed

packing. Loose fit.

NOTE

Suit plugs are red on one end and larger

than the valves.

9

•

Exhalation

Ensure valves are installed for the tether

Suit arranged for the

Valves/Plugs

system and plugs are installed for the

wrong system.

rebreather system.

Change 1

2-8