T.O. 33B-1-1

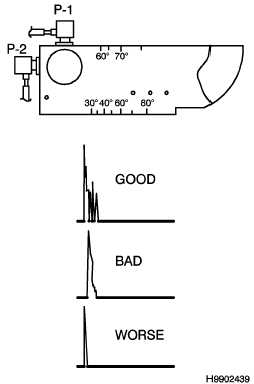

Figure 1-14.

Use of IIW Block to Check Entry Surface Resolution

1.8.2.4.3

Checking Entry Surface Resolution with ASTM Blocks.

a.

Use an ASTM block with a #5 FBH, or other size if specified. Choose a block with a metal travel

distance according to the frequency being used (see Table 1-8).

b.

Maximize the separation between the initial pulse and the hole signal.

c.

Check that the hole signal is actually the indication of the first echo from the hole by noting the

position of the hole signal on the calibrated distance scale of the waveform display. The distance

should be the actual depth of the hole.

d.

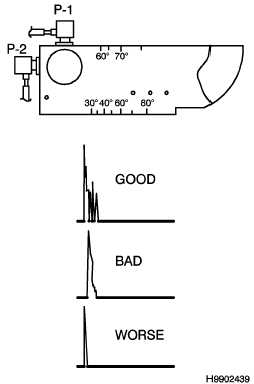

Evaluate the waveform patterns.

1.8.2.5

Distance Calibration of A Scan.

1.8.2.5.1

Straight Beam Distance Calibration for Weld Inspection (IIW Block).

a.

Position the search unit on an IIW block at P-1, P-2 or P-3 as shown in Figure 1-15. This distance

between multiple back ref lections is as follows:

(1)

1.00 inch at P-1

(2)

4.00 inch at P-2

(3)

8.00 inch at P-3

1-62

Change 2