T.O. 33B-1-1

5-79

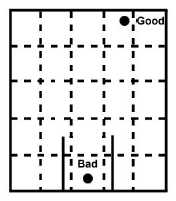

Figure 5-79. Mechanical Impedance Analysis Display.

5.4.6.5

Eddy-Sonic Method.

Since this method is based on the generation of eddy currents in the test part, it will work only on metal structures. The

instrument sends electrical pulses, with frequencies in the low kilohertz range, to a coil in the probe. The resultant

pulsating magnetic field produces eddy currents in the part; the eddy currents cause the part to vibrate, and a

microphone on the axis of the coil detects the sonic vibrations. Unbonds cause changes in the vibrational response of

the part. The detected changes produce an indication on a meter or an LED array. The probe usually has a mechanical

lift-off adjustment that sets the air gap between the coil and the test surface to minimize the noise produced by probe

scanning. This method works best on metallic honeycomb structures with thin skins (0.062 inch or less). Other

methods do as well on such configurations, and because the eddy-sonic is rather limited in its application, it is not

commonly used.

NOTE

For a reliable bond inspection, the inspection surfaces of the test part must be free of

loose paint and foreign matter.

CAUTION

Gradual changes in indications on an instrument display should be evaluated to see

if the part thickness is changing. If the part thickness has changed, recalibration is

required. When possible, scanning should be performed in directions of constant

thickness.

Figure 5-80. Typical Multiple Mode Bond Tester.