T.O. 33B-1-1

5-11

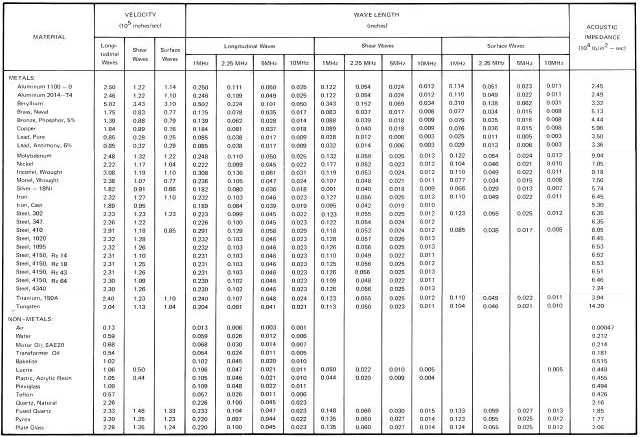

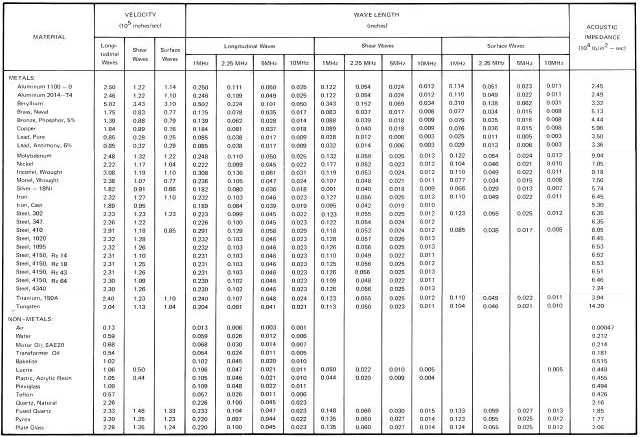

Table 5-2. Ultrasonic Properties of Materials

5.1.6

Ultrasonic System Variables.

An ultrasonic inspection is affected by several variables. The ultrasonic inspection system consists of the instrument,

search unit, wedges or shoes, coupling medium, etc. Discussion of variables related to the test part and to

discontinuities follows in the paragraphs describing system variables. It is important that the operator be familiar with

and recognize the effects of all these variables.

5.1.6.1

Frequency.

For flaw detection using the contact method, frequencies between 2.25 and 10 MHz are commonly used. The higher

frequencies in this range provide greater sensitivity for detection of small discontinuities, but do not have the

penetrating power of the lower frequencies. The higher frequencies are also more affected by metallurgical

discontinuities in the structure. Signals from these discontinuities can often interfere with the detection of relevant

discontinuities, such as small cracks. The size of the defect that must be detected should be the prime consideration

when selecting the frequency. If the defect size of interest is large, a low frequency, such as 2.25 MHz, can be used for

greater penetration if required. Under favorable conditions, defects must have at least one dimension equal to or

greater than ½ the wavelength in order to be detected. For example, straight beam inspection of aluminum (1100-0) at

2.25 MHz with a wavelength of 0.111 inch requires a defect be 0.066 inch or larger in order to be detected. At 5 MHz,

the minimum defect size is 0.025 inch. At 10 MHz, it is 0.012 inch.