T.O. 33B-1-1

5-9

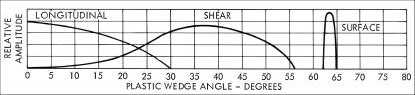

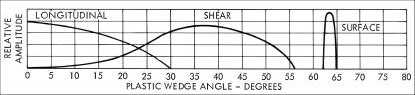

of the refracted beams are determined by Snell's law. Figure 5-11 shows the relative energy for shear, longitudinal, and

surface wave beams in steel for different incident angles of longitudinal waves in plastic. The curves shown were

obtained using plastic wedges on steel. Similar shaped curves can be obtained for other test materials, such as

aluminum and titanium. Similar curves can also be generated for the immersion mode of inspection with the plastic

replaced by water. Refraction angles are greater with water than plastic.

a. The incident angle at which the refracted angle for longitudinal waves reaches 90 degrees is called the

first critical angle. At incident angles equal to or greater than this critical angle, longitudinal waves no

longer exist in the material. Beyond this angle, only shear waves remain in the test material.

Figure 5-11. Relative Amplitude in Steel of Longitudinal, Shear and Surface

Wave Modes with Changing Plastic Wedge Angle.

b. The incident angle at which the refracted angle for shear waves reaches 90 degrees is called the second

critical angle. At incident angles equal to or greater than this, shear waves are no longer generated in

the material. Instead, surface waves are propagated along the surface of the material.

c. Figure 5-11 shows the first critical angle in plastic for steel is approximately 30 degrees; the second

critical angle is approximately 56 degrees.

d. Incident angles useful for shear-wave NDI fall between the two critical angles.

5.1.5.3

Obtaining the Required Refracted Beam.

Field NDI personnel are responsible for using the correct refracted beam angle for a particular application. The

specific procedure details the correct refracted beam angle. However, it is important for the field NDI inspector to

know how the correct angle was obtained. Snell's law is the tool for determining wedge angles for contact testing, or

the angle of incidence in water for immersion testing. The following example shows how Snell's law is used to

determine the angle of incidence in plastic needed to generate 45-degree shear waves in aluminum:

f2 = 45°; sin 45 = 0.707

v1 = velocity of longitudinal wave in plastic wedge = 1.05 x 105 in/sec (from Table 5-2)

v2 = velocity of shear waves in aluminum = 1.22 x 105 in/sec (from Table 5-2)

sin

sin

f

f

1

2

1

2

=v

v

;

sin

.

.

.

f

1

5

5

0

707

1

05x10

1

22

10

=

x

or sin

( .

)( .

)

.

.

f1

5

5

0

707

1

05x10

1

22

10

0

608

=

=

x

Therefore, f1 = 37.5° (from Table 5-1)

NOTE

Then determining an angle, use the angle having the sine value closest to the

calculated sine value. For example, if sin f1 = 0.591, Table 5-1 shows sin 36 =

0.5878 and sin 37 = 0.5984. Since 0.5878 is closer to 0.591, select 36.