T.O. 33B-1-1

3-16

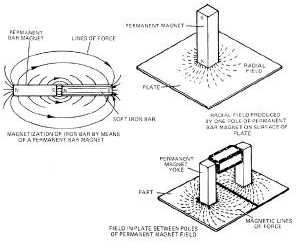

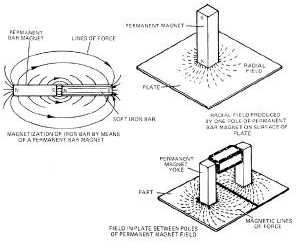

strength is adequate. Outside this limited area, the field spreads out, and cracks favorably located with respect to field

direction may or may not be shown, again depending on the place where they occur. Figure 3-19 illustrates the uses of

permanent magnets for magnetization of parts. This method of magnetization should be used only by experienced

operators who are aware of and understand the limitations of the technique.

Figure 3-19. Magnetization with a Permanent Magnet

3.1.9.11.2

Some of the other drawbacks to the use of permanent magnets are:

a. The strength of the field is not continuously variable.

b. Large areas or masses cannot be magnetized with enough strength to produce satisfactory crack

indication

c. It may be difficult to remove a strong magnet once it is in contact with the part.

3.1.9.12

Special Purpose Equipment.

Special units are those, which have been specifically designed to take, care of unusual situations where standard units

are inappropriate. They may be special as to the method of magnetization or particle application, or be designed to

handle unusual size, shape, or number of parts. They may or may not be automatic. Special units can be further

broken down into two groups:

a. Special-purpose units are those that are built to do a single testing job. This special job may be a

variation in magnetization technique, in the way the magnetic particles are applied, or in the way parts

are handled. They may be for a single-purpose in which case they are to test a single type of part and

no other possibly by a special processing technique. They may be general-purpose, in which case they

are designed to apply a special magnetization or processing technique to a variety of parts.

b. Automatic units are those in which part or all of the handling and processing steps are performed

automatically. Either single-purpose or general-purpose units may be partly or entirely automatic.

Even standard units, by addition of standard accessories, may be made automatic in some of their

functions. The principal purpose of automatic units is to speed up the inspection cycle. This is

accomplished through automation of one or more of the important steps involved in any given testing

operation.