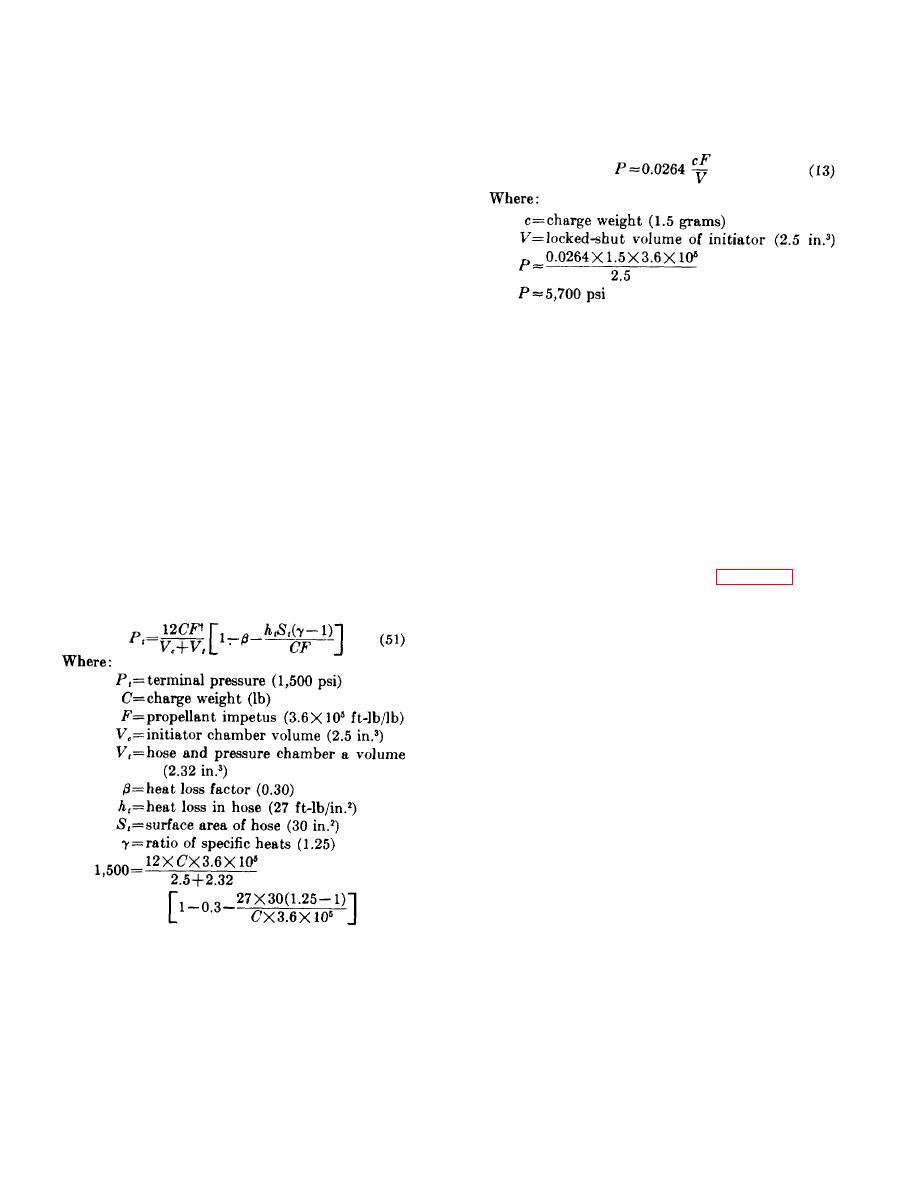

1,500 = 9.0 X 105C(0.7 - 56 X 10-5C-1) C = 3.2 X 10-3

Lanyard travel .....................3/4-inch.

Generated pressure.............1,500 psi in a 1.00 in.3

pounds = 1.5 grams

chamber at end of a

e. With this calculated charge, the locked-shut

4-foot hose.

pressure may be estimated with equation (13).

Ignition delay ......................2 seconds.

84. First Order Approximations . a. The propellant

charge must be calculated prior to estimating the peak

pressure which the device must be designed to

withstand. The propellant charge can be calculated on

the basis of the pressure which is to be generated in the

pressure gage chamber and the volumes of the pressure

chamber, hose, and initiator chamber.

b. The volume of the pressure gage chamber is

f. The device, therefore, should be designed to

specified as 1.00 cubic inch. The volume of the hose

withstand a maximum locked-shut pressure of 5,700

can be calculated by multiplying the cross-sectional area

psi.‡ The approximations from which the charge is

(0.0276 sq in.) by the length of the hose in inches, and

calculated must be accurate enough so that a total

the volume of the initiator can be estimated from the

redesign of the components will not be necessary when

envelope dimensions.

the actual locked-shut pressure is determined.

c. The initial volume of the chamber (2.5 cu in.) is

computed from its dimensions, taking into account the

85. Component Layout. a. A rough estimate of

firing pin, housing, and cartridge retainer.

When

envelope size has been obtained during the first-order

calculating initial volumes, the case volume is included

approximations. The firing mechanism and cartridge

in the initial volumes, since the instant the cartridge

are designed to fit into the estimated envelope. The

fires, the cartridge case opens and it becomes part of

mounting flange, chamber, cap, firing pin, firing pin

the internal volume.).

housing, cartridge, cartridge retainer, initiator pin,

d. The computed volumes and equation (51) are

initiator spring, and firing pin release balls are designed

used to determine the propellant charge. Since it

in conjunction with the estimated envelope and firing

generally is desirable to burn the propellant as rapidly as

mechanism and cartridge designs. Figure 76 shows the

possible, a fast-burning propellant, such as M2, is

layout of components of the initiator.

selected. The charge weight is computed as follows:

b. The initiator is operated mechanically by

exerting a 20- to 35-pound pull on the initiator pin.

The firing pin is locked to the initiator pin by 3 balls.

Withdrawing the initiator pin retracts the firing pin,

compressing the initiator spring. When the firing-pin-

release balls pass from the smaller to the larger

diameter bore in the firing-pin housing, the balls leave

the initiator pin locking groove, permitting the initiator

pin and firing pin to separate and the compressed

initiator spring to drive the firing pin toward the primer.

The firing-pin-release balls are returned to their original

position in the recess as the firing pin moves into the

smaller diameter bore. As the firing pin completes its

travel, the firing pin tip passes through the small hole in

the forward end of the firing pin housing, striking the

cartridge. The motion of the firing pin is arrested by the

† A factor of 12 is introduced to permit Pt to be expressed in psi.

‡ A workhorse model is fabricated to withstand a pressure far in excess of 6,000 psi and charge-verification firings

are conducted. The calculated charge, 1.5 grams of M2 propellant, is the first charge used In the workhorse model.

After the charge has been modified to meet the design requirements, locked-shut firings determine the actual pressure

which the initiator must withstand.

91