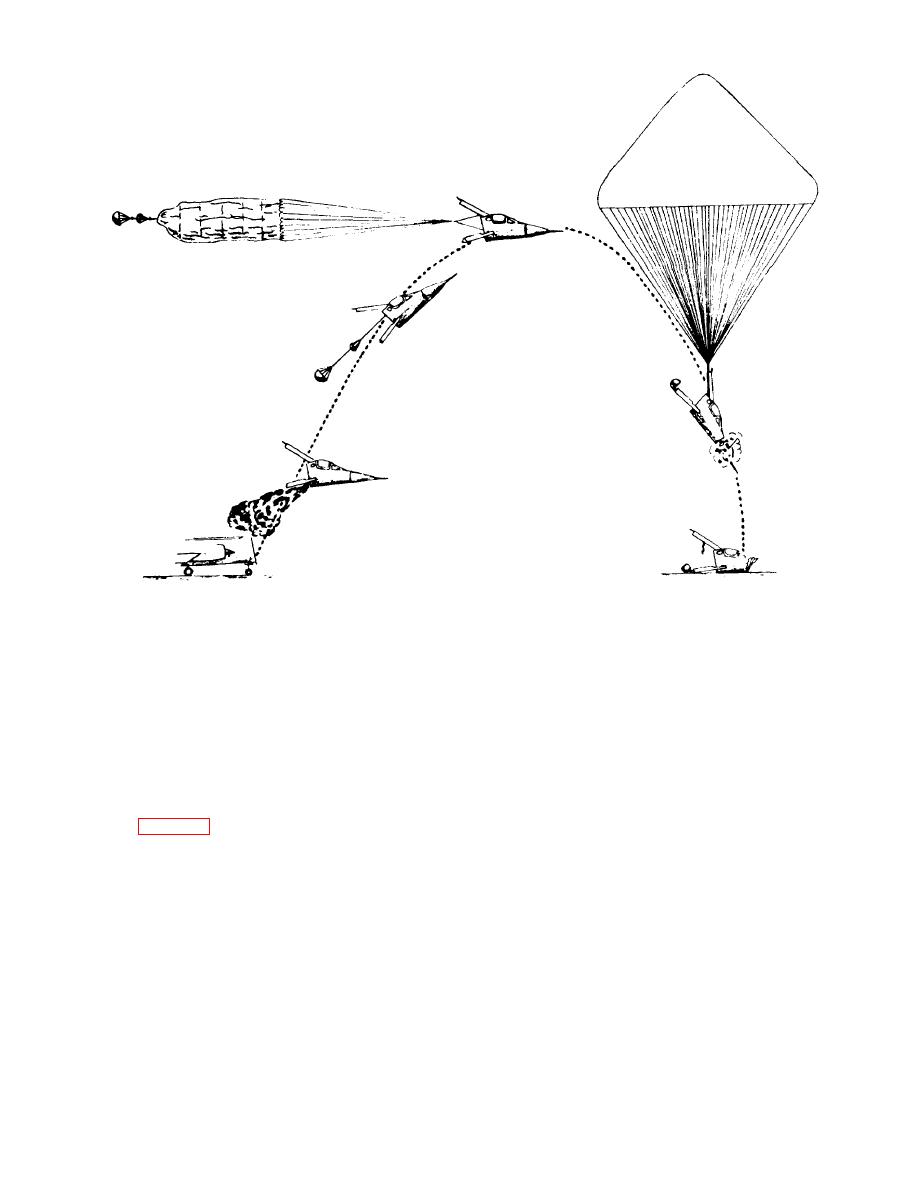

Figure 14. "Off the runway" ejection sequence.

area, the hydraulic fluid is pressurized to

propellant contained in the chamber. As

3,000 psi as the piston is stroked. The

this propellant burns, it ignites the main

fluid is forced through the actuating

propellant charge (sustainer) contained in

mechanism (5) and the spent fluid is

the series of tubes which makes up the

returned to the opposite side of the piston

gas generator. The walls of the propellant

at a low pressure. When the piston

grains are inhibited so the propellant must

bottoms, the shift valve (2) exhausts the

burn from end to end as a cigarette. As

high pressure gas and reverses the

the stub end of the propellant stick burns,

direction of the gas piston. The hydraulic

it ignites a primer cord which ignites the

fluid becomes pressurized in the opposite

propellant in the next tube, and so the

direction, and these cycles continue until

burning continues for 8 minutes.

burnout of propellant in the gas generator

(5) Figure 16 shows the entire auxiliary power

occurs (approximately 8 minutes).

supply system. The gas produced by the

(6) The surge accumulator (6) absorbs surges

burning propellant passes through a filter

of fluid and maintains a constant flow

in the gas generator, through an external

when the pump reverses direction. The

filter and pressure release valve, into a

oil reservoir (7) contains the fluid

shift valve (2), where it is directed into

displaced when the piston rod is in the

one end of a double-acting pump. The

pump chamber and provides back

double-acting pump transforms gas

pressure in the system.

energy (3) to hydraulic fluid energy (4).

By means of a 2 to 1 differential piston

17