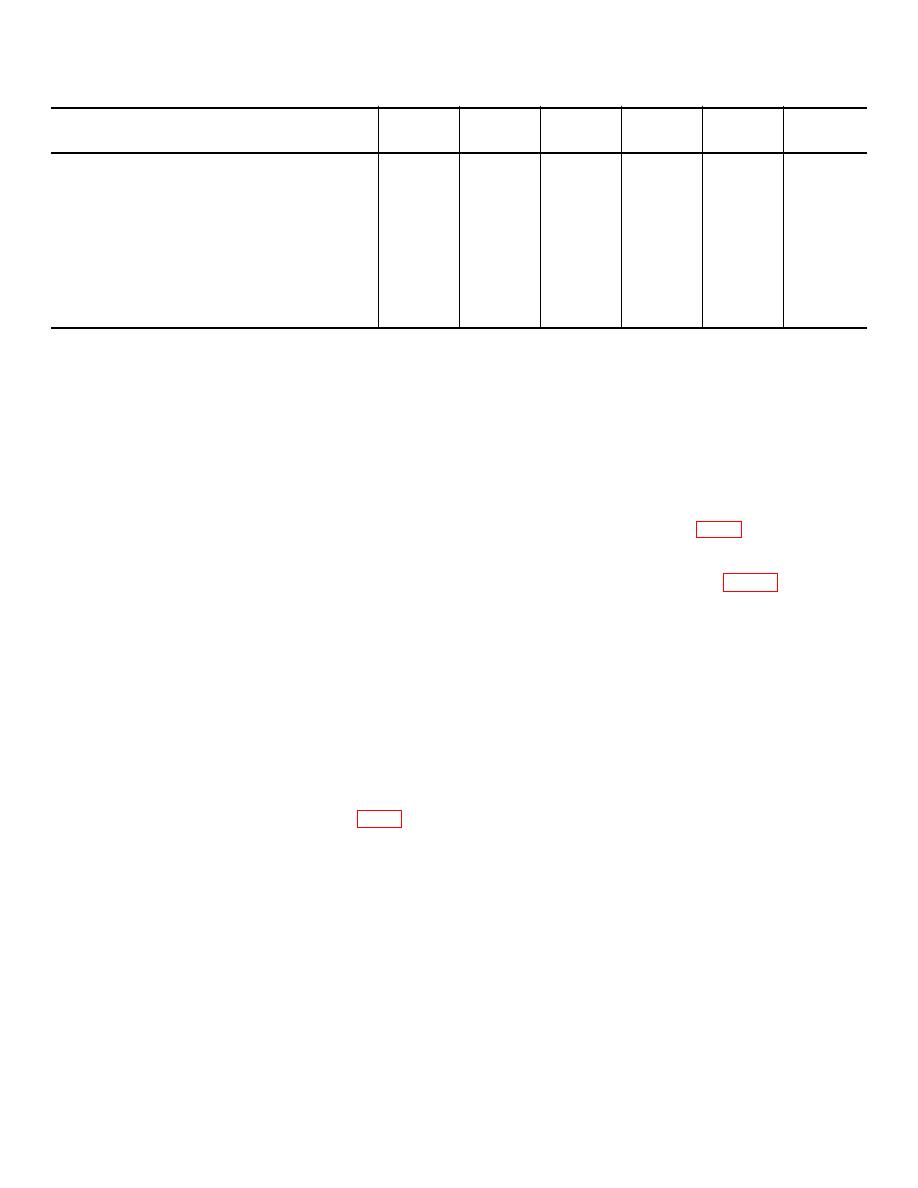

Table VI. Comparative Data for Removers

Stroke

Weight

Peak

Stroke

Method

Weight of

(in.)

propelled

thrust

time

of

device

(lb)

(lb)

(sec)

initiation

(lb)

T18† ................................................................

12

320

6,000

------

Gas

19.0

M4 ...................................................................

19

300

4,100

0.1

Gas

3.8

M5 ...................................................................

19

1,000

8,100

0.15

Gas

3.9

M1A1 ...............................................................

23

311

3,040

0.13

Mechanical

2.1

T13E1 ..............................................................

23

1,000

5,500

0.2

Gas

------

T19† ................................................................

24

230

6,000

------

Gas

25.5

M3 ...................................................................

26

311

3,145

0.15

Gas

4.4

T8 ....................................................................

26

300

3,100

0.15

Gas

4.3

M2A1 ...............................................................

28

311

3,145

0.15

Gas

4.4

† Electromechanical-ballistic canopy remover-actuator.

flexible hose or tubing to initiate other

human physiological limitations are not a

propellant actuated devices.

In this

factor. The only limit on acceleration and

application, the thruster ensures the

rate of change of acceleration is the

proper sequencing of operations.

An

strength of the aircraft structure.

example is one of the T25 thrusters used

(2) Electro-mechanical

removers,

not

in the F-106B aircraft escape system.

illustrated, utilize an aircraft's electrical

This thruster unlocks the canopy and, at

power system to allow operation of the

the completion of stroke (after the canopy

canopy in normal use. In emergencies,

is unlocked), bypasses gas to fire the

jettisoning of the canopy is accomplished

canopy remover (fig. 6). Each thruster is

by means of a ballistic system initiated by

designed to operate against specific

the pilot or other crew member.

constant or varying forces.

d. Thrusters.

(1) The thruster was developed to exert a

body, an outside tube (slug), a firing mechanism, and a

thrust, through a short stroke, to move a

cartridge. When the cartridge fires, the expanding

weight or to oppose a force. The device

propellant gas ejects the slug and extracts the load to

consists of a chamber, piston, firing

which it is attached. A series of electrically and gas

mechanism, and a cartridge. Thrusters

initiated ejectors has been developed to eject drag

have been used for operations such as

parachutes. Table VII presents comparative data on the

seat positioning, stowing of equipment,

size and performance of existing ejectors. This table

hatch or canopy unlock, and canopy

like all of the others, is presented merely to show the

ejection. Thrusters are closed devices;

range of devices already developed as a guide for

that is, the main piston does not separate

determining the feasibility of proposed devices.

from the device under any operating

Ejectors are applicable to many missile and drone

condition including "locked-shut" and "no-

recovery systems and have potential Use as automatic

load" firings.

mortar, grenade, or rocket launchers and for chest type

(2) Buffer or damper mechanisms (fig. 5) are

reserve parachute deployment.

used occasionally in conjunction with

thrusters and, in some cases, are made

9. Special Purpose Devices. a. General. A number

an integral part of the thruster. They are

of propellant actuated devices have been developed for

used to restrict the velocity and

"special" applications. Included in this category are

acceleration of the propelled load

cutters, releases, and electric ignition elements.

because

of

structural

or

human

b. Cutter. Cable cutters have been developed that

physiological limitations. Thrusters have

sever cables (such as electrical cables) prior to the

been developed that function in their

removal or ejection of a canopy or seat, or the firing of a

usual manner, but also at the end of a

missile. Although most cable cutters were developed to

stroke, bypass gas through high-pressure

sever a single cable, a cutter (T3) was designed to sever

8