TM 5-3740-218-13&P

4-10.

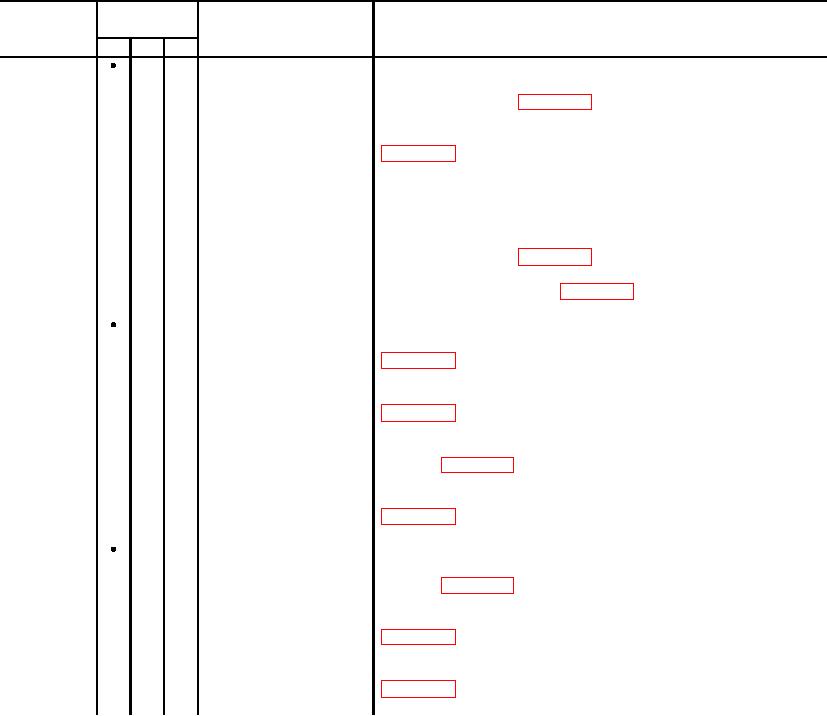

PMCS TABLE

Table 4-1. Unit Level PMCS (Cont)

NOTE: Within designated interval, these checks are to be performed in the order listed.

M-Monthly

S-Semiannually

A-Annually

ITEM

INTERVAL

ITEM TO BE

NO.

INSPECTED

PROCEDURE

MS

A

15

LV Boom and

Check boom assembly (both sides) for obvious

Nozzles

exterior damage such as nicks, dents, or cracks.

Replace as required (para 4-46).

Check plastic nozzles for cross threading, nozzle

ends for obstruction. Replace or clean nozzles

Ensure spraying disc and core seal are properly

installed in quickjet cap.

Ensure quickjet cap is screwed on securely to

nozzle body. Secure cap.

Check for missing or damaged quick-release pins.

Replace as required (para 4-46).

Check quick-release pin mount holes for elongation.

Replace boom as required (para 4-46).

16

ULV Boom and

Check boom assembly for external damage such as

Rotary Atomizers

nicks, dents, or cracks. Replace as required

Check rotary atomizers for freedom of rotation and

obstruction. Clean or replace as required

Check hydraulic fittings for Class III leaks and

hoses for damage. Repair leaks or replace hoses as

required (para 4-48).

Check attaching hardware such as clamps and pins

for damage and security. Replace as required

17

Hopper Assembly

Check left and right hopper assemblies for exterior

damage such as dents or cracks. Replace as

required (para 4-53).

Check capacitive light switch and harness for

proper installation, damage, and security. Replace

(para 4-54) or tighten as necessary.

Check hydraulic cylinders and fittings for Class III

leaks. Repair leaks at fittings or replace cylinder

Check chutes for foreign objects. Clean as required.