TM 5-3740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

FORMULATION TANK WILL NOT HOLD PRESSURE (Continued)

(1)

If the test pressure gage reads 10 psi or less, replace the pressure regulator and go to Step 3d.

(2)

If the test pressure gage reads more than 15 psi, replace the safety valve and the pressure

regulator and go to Step 3d.

(3)

If the test pressure gage is equal to the tank pressure gage, the tank pressure gage is ok. Go to

3d.

(4)

If the test pressure gage and the tank pressure gage are not equal, replace the tank pressure

gage. Go to Step 3d.

d.

Close the pressure drain valve and pressurize the tank. Let it sit for 5-10 minutes.

(1)

If the tank holds 11-14 psi pressure, the problem is solved.

(2)

If the tank does not hold 11-14 psi, go to Step 4.

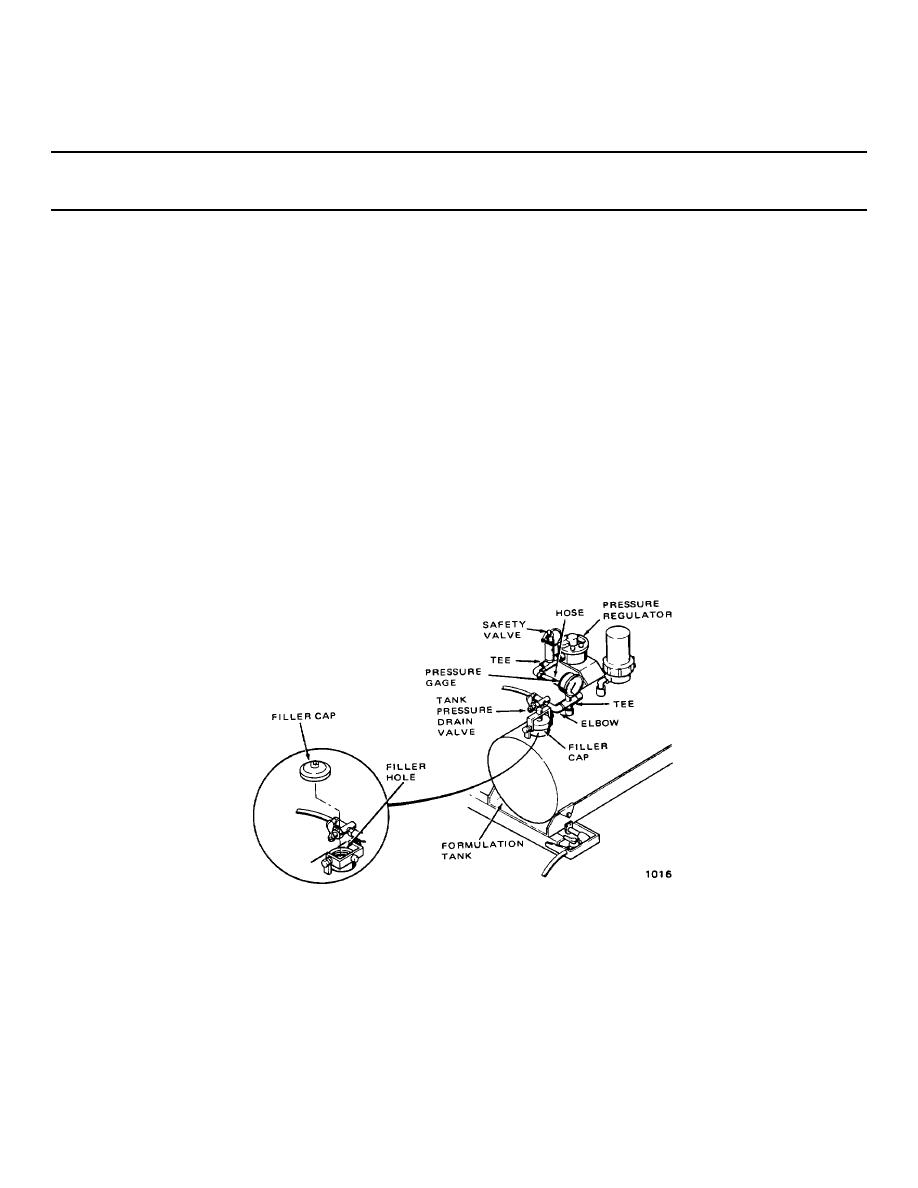

Figure 5-202. Formulation Tank Filler Cap

5-187