TM 5-3740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

FORMULATION TANK WILL NOT HOLD PRESSURE (Continued)

(1)

If the tank holds the 11-14 psi pressure, the problem is solved.

(2)

If the tank does not hold the 11-14 psi pressure and there are no more leaks, go to Step 3.

Step 3.

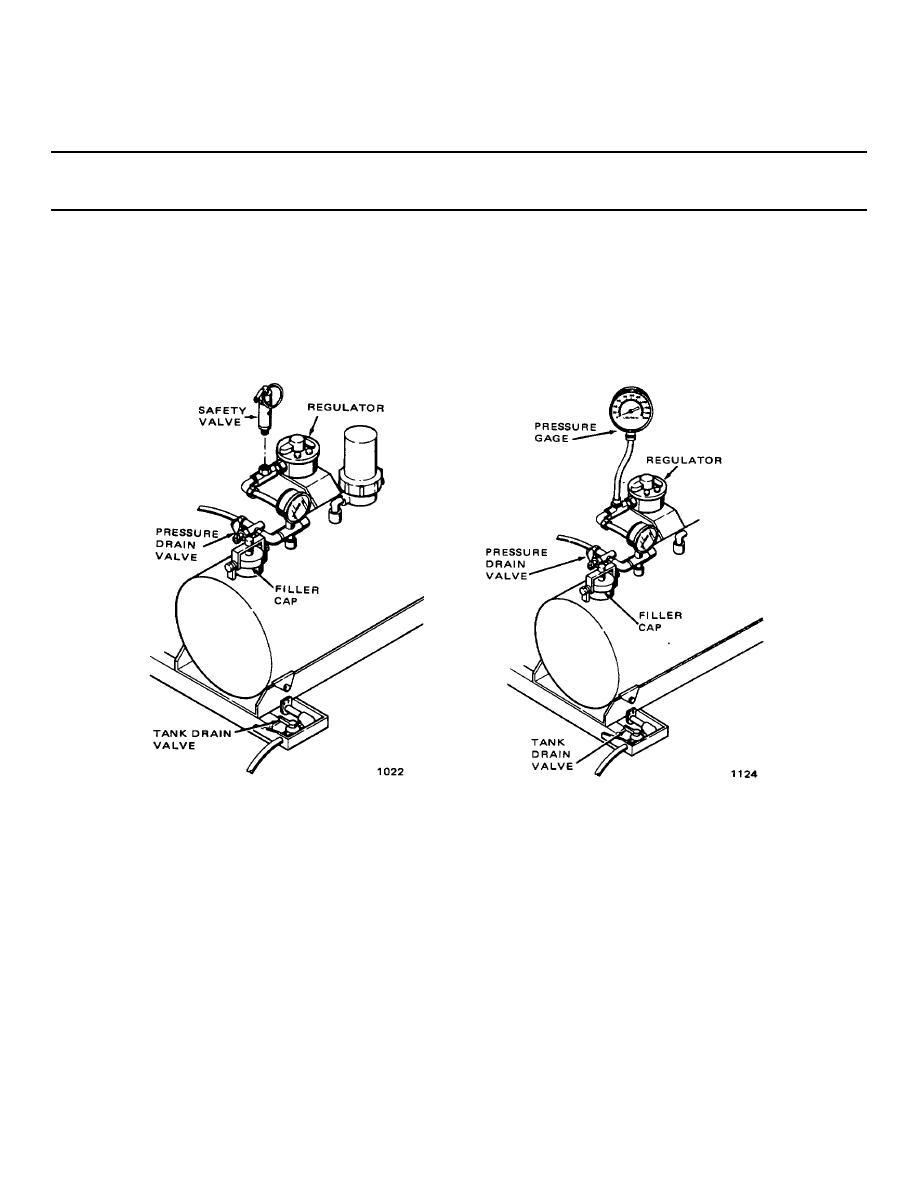

Check the safety valve, the pressure regulator and the tank pressure gage. Use a test pressure gage.

Figure 5-201. Pressure Gage Installation

a.

Remove the safety valve from the tee.

b.

Insert a test pressure gage into the tee.

c.

Start the engine and pressurize the formulation tank.

WARNING

BE SURE to open the pressure drain valve and release the tank pressure before replacing any

parts.

5-186